High-strength flexible transparent wear-resistant hardened coating on surface of folding screen and preparation method thereof

A hardened coating and high-strength technology, which is applied in chemical instruments and methods, preparation of organic compounds, coatings, etc., can solve the problem that the wear resistance of the coating cannot achieve better results, the limit of bending times, hardness and coating The flexibility of the layer is difficult to achieve the effect of improving the transparent display effect, improving the wear resistance, and improving the shading coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

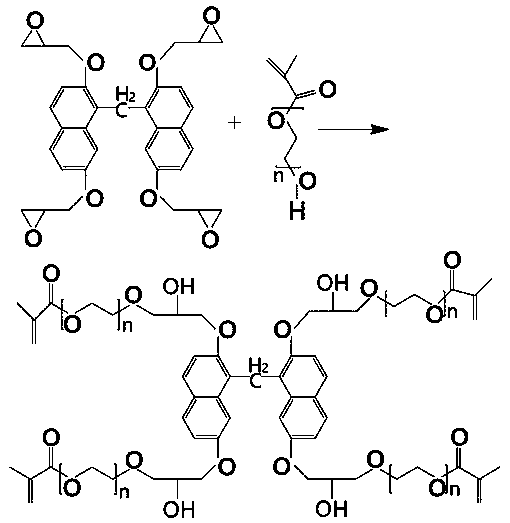

[0025] (1) Synthesis of Naphthalene Cyclic Polyethylene Glycol Acrylate

[0026] In solvent A, add a naphthalene ring-type tetrafunctional epoxy resin (HP-4700 from DIC Japan), polyethylene glycol methacrylate and a basic catalyst, and react at a temperature of 80°C for 1 hour, after purification Naphthalene ring-type polyethylene glycol acrylate can be obtained, wherein the mass ratio of naphthalene ring-type tetrafunctional epoxy resin, polyethylene glycol methacrylate and basic catalyst is 1:1:0.01, and its synthetic route As shown in the following formula:

[0027]

[0028] where n is 5;

[0029] The basic catalyst is triethylamine, and the solvent A is formamide.

[0030] (2) Preparation of UV curing hardening solution

[0031] Uniformly mix naphthalene ring type polyethylene glycol acrylate, diluent, photoinitiator and octavinyl-POSS to obtain UV curing hardening solution, naphthalene ring type polyethylene glycol acrylate, diluent, photoinitiator and The octaviny...

Embodiment 2

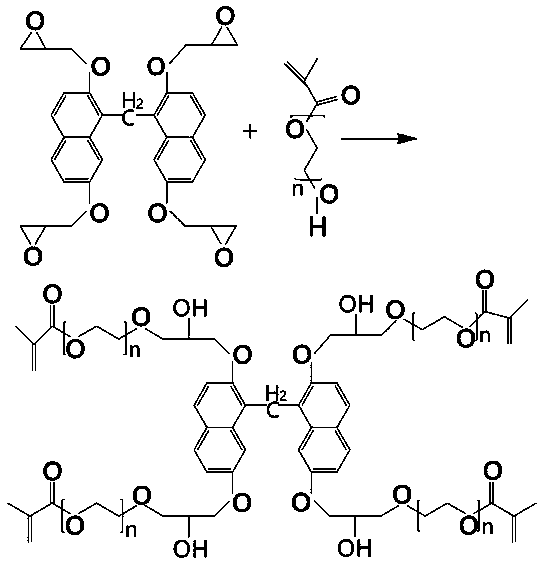

[0035] (1) Synthesis of Naphthalene Cyclic Polyethylene Glycol Acrylate

[0036] In solvent A, add a naphthalene ring-type tetrafunctional epoxy resin (HP-4700 from DIC Japan), polyethylene glycol methacrylate and a basic catalyst, and react at a temperature of 120°C for 4 hours, after purification Naphthalene ring-type polyethylene glycol acrylate can be obtained, wherein the mass ratio of naphthalene ring-type tetrafunctional epoxy resin, polyethylene glycol methacrylate and basic catalyst is 1:5:0.04, and its synthetic route As shown in the following formula:

[0037]

[0038] where n is 15;

[0039] The basic catalyst is sodium hydroxide, and the solvent A is tetramethylethylenediamine.

[0040] (2) Preparation of UV curing hardening solution

[0041] Mix naphthalene ring-type polyethylene glycol acrylate, diluent, photoinitiator and octavinyl-POSS evenly to obtain UV curing liquid, in which naphthalene ring type polyethylene glycol acrylate, diluent, photoinitiator T...

Embodiment 3

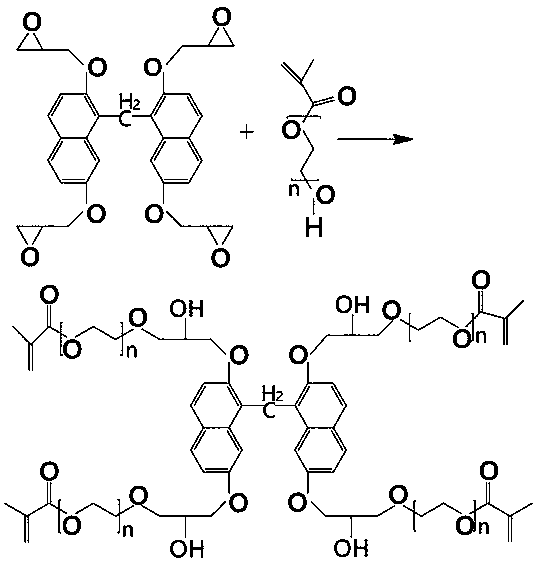

[0045] (1) Synthesis of Naphthalene Cyclic Polyethylene Glycol Acrylate

[0046] In solvent A, add a naphthalene ring-type tetrafunctional epoxy resin (HP-4700 from DIC Japan), polyethylene glycol methacrylate and a basic catalyst, and react at a temperature of 120°C for 4 hours, after purification Naphthalene ring-type polyethylene glycol acrylate can be obtained, wherein the mass ratio of naphthalene ring-type tetrafunctional epoxy resin, polyethylene glycol methacrylate and basic catalyst is 1:1:0.01, and its synthetic route As shown in the following formula:

[0047]

[0048] where n is 10;

[0049] The basic catalyst is potassium carbonate, and the solvent A is dioxane.

[0050] (2) Preparation of UV curing hardening solution

[0051] Mix naphthalene ring-type polyethylene glycol acrylate, diluent, photoinitiator and octavinyl-POSS evenly to obtain UV curing liquid, in which naphthalene ring type polyethylene glycol acrylate, diluent, photoinitiator The mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com