A kind of high toughness, impact resistance, high flexibility epoxy potting glue and preparation method thereof

An impact-resistant, potting adhesive technology, applied in the field of potting adhesives, can solve problems such as insufficient cross-linking density, lower heat resistance, and insufficient rigidity of cured products, and achieve stable curing rate, small heat release, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

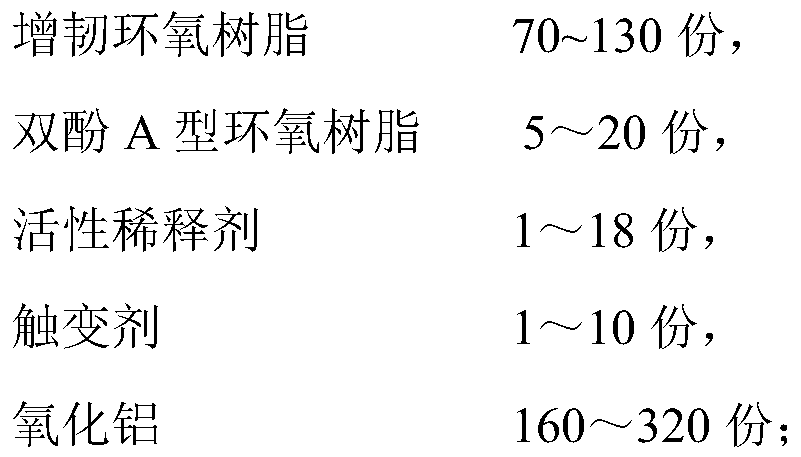

[0039] A high-toughness, impact-resistant, high-flexibility epoxy potting adhesive of the present invention, comprising A component and B component with a mass ratio of 10:1, wherein A component is composed of the following raw materials:

[0040]

[0041] Component B consists of the following raw materials:

[0042] Mixture of Huntsman D230 and T403 35g;

[0043] Hyperbranched curing agent (complex of hyperbranched polyethyleneimine and isophorone diamine) 25g and DMP-302g.

[0044] The preparation method of the high toughness, impact resistance and high flexibility epoxy potting glue of the present embodiment comprises the following steps:

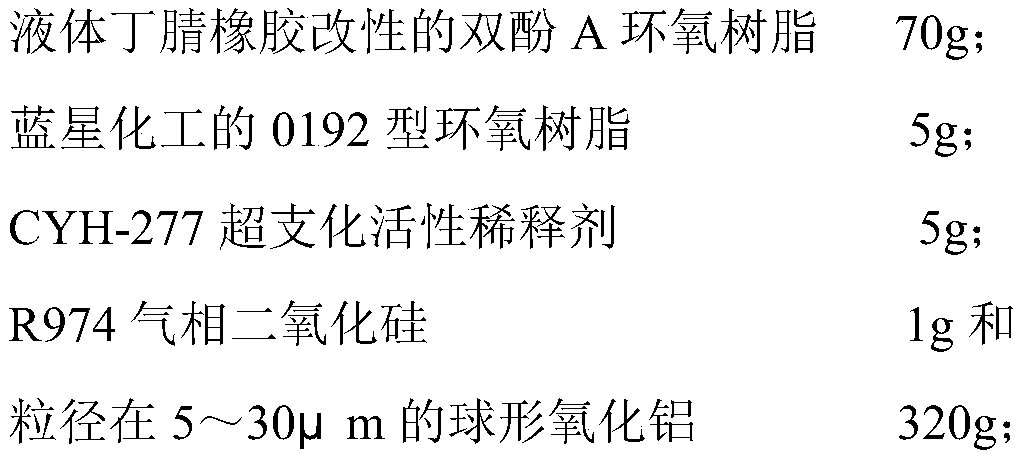

[0045] (1) Preparation of matrix resin component system (component A): add 70g of liquid nitrile rubber-modified bisphenol A epoxy resin to the high-speed disperser kettle, and then add 5g of Bluestar Chemical’s 0192 type After the CYH-277 hyperbranched reactive diluent of epoxy resin, 5g is mixed homogeneously, then add the R974 fume...

Embodiment 2

[0049] A high toughness, impact resistance and high flexibility epoxy potting compound of the present invention, comprising A component and B component with a mass ratio of 15:1, wherein A component is composed of the following raw materials:

[0050]

[0051] Component B consists of the following raw materials:

[0052] Mixture of Huntsman D2000 and T403 20g;

[0053] Hyperbranched curing agent (complex of hyperbranched polyethyleneimine and isophorone diamine) 40g and triethanolamine 3g.

[0054] The preparation method of the high toughness, impact resistance and high flexibility epoxy potting glue of the present embodiment comprises the following steps:

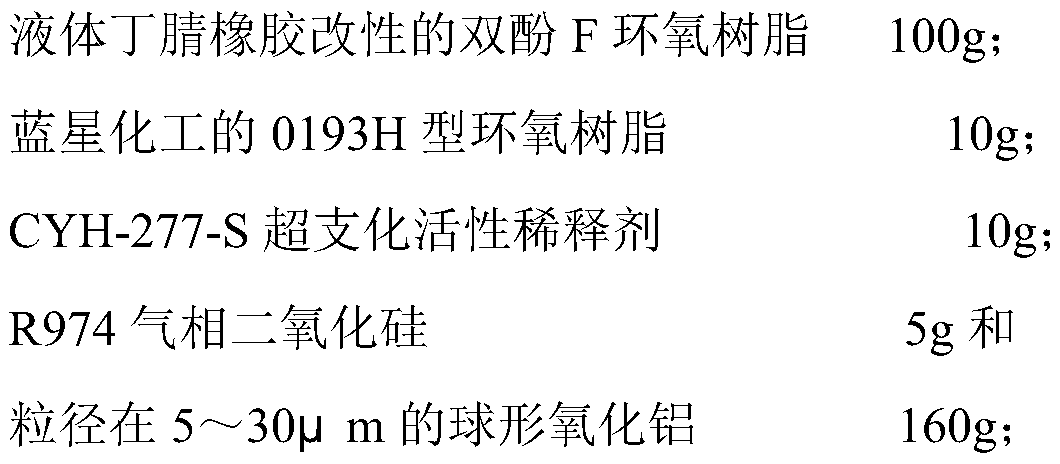

[0055] (1) Preparation of the matrix resin component system (component A): add 100g of liquid nitrile rubber-modified bisphenol F epoxy resin to the high-speed disperser kettle, and then add 10g of Bluestar Chemical’s 0193H type Epoxy resin, 10g of CYH-277-S hyperbranched reactive diluent are mixed evenly, then add 5g...

Embodiment 3

[0059] A high-toughness, impact-resistant, high-flexibility epoxy potting adhesive of the present invention, comprising A component and B component with a mass ratio of 20:1, wherein A component is composed of the following raw materials:

[0060]

[0061] Component B consists of the following raw materials:

[0062] Huntsman ED-600 and EDR-176 mixture 50g;

[0063] Hyperbranched curing agent (complex of hyperbranched polyethyleneimine and isophorone diamine) 50g and resorcinol 5g.

[0064] The preparation method of the high toughness, impact resistance and high flexibility epoxy potting glue of the present embodiment comprises the following steps:

[0065] (1) Preparation of matrix resin component system (component A): add 130g of liquid nitrile rubber-modified bisphenol A epoxy resin to the high-speed disperser kettle, and then add 20g of Bluestar Chemical’s 0191H type Epoxy resin, 18 parts of CYH-277-S hyperbranched reactive diluent are mixed evenly, then add 10 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com