3D biological printing ink as well as preparation method and application thereof

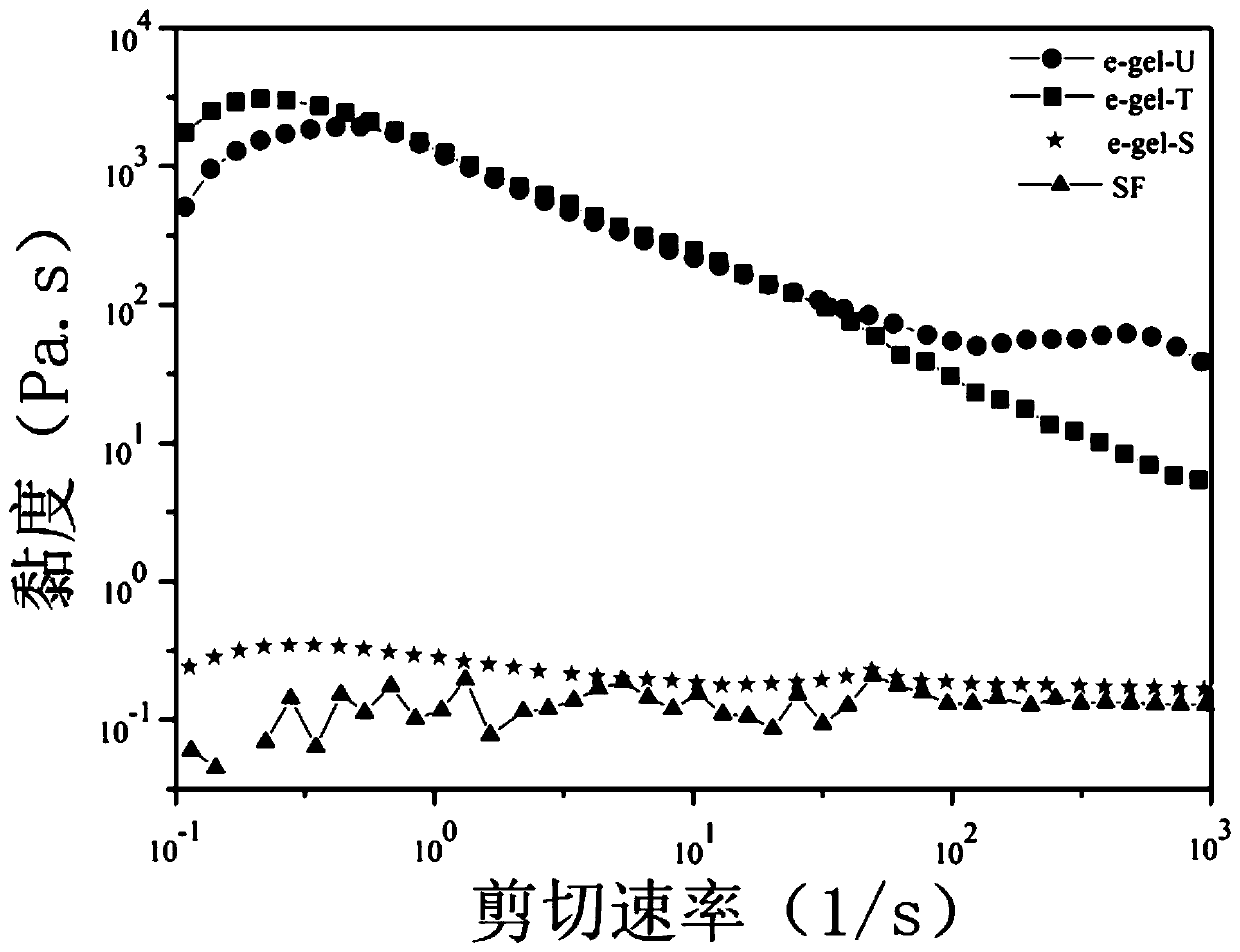

A bioprinting and 3D printing technology, applied in the field of 3D printing, can solve the problems such as the failure to fully display the biological properties of silk fibroin materials, the reduction of silk fibroin content, the adverse effects of chemical reagents on the long-term growth behavior of cells, and achieve excellent biological properties. , Improve printability, optimize the effect of rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, a preparation method of 3D bioprinting ink for 3D bioprinting bone defect scaffold is provided, the method comprises the following steps:

[0051] Step 1, preparing silk fibroin aqueous solution;

[0052] Silk fibroin aqueous solution is obtained after degumming, dissolving, dialysis and centrifugation. Degumming, dissolving, and dialysis processes all adopt common technical means in this field. For details, reference can be made to the literature Rockwood D N, Preda R C, Yücel, Tuna, et al.Materials fabrication from Bombyx mori silk fibroin[J].Nature Protocols,2011,6(10) :1612-1631.. Wherein, the molecular weight cut-off of the dialysis bag used in the dialysis process is 3500kDa. The concentration of the finally prepared silk fibroin aqueous solution is 10wt%.

[0053] Step 2, the silk fibroin aqueous solution is made into a silk fibroin electrogel under the action of a stable electric field;

[0054] The silk fibroin aqueous solution prepared ...

Embodiment 2

[0059] In this example, the pure silk fibroin 3D bioprinting ink 3D printing gel scaffold prepared in Example 1 is provided.

[0060] Put the pure silk fibroin 3D bioprinting ink prepared in Example 1 on the 3D printer, open the 3D printer control panel, set the temperature of the nozzle to 5°C, and place the pure silk fibroin 3D bioprinting ink on the nozzle for temperature pre-control for 15 minutes , so that the pure silk fibroin 3D bioprinting ink reaches the preset nozzle temperature. Use the platform to receive the printed holder, and the temperature of the platform is set to 5 °C. 3D print the pure silk fibroin gel scaffold according to the model set by the 3D printer, see the 3D printed pure silk fibroin gel scaffold Figure 5 , the number of layers is 10.

Embodiment 3

[0062] In this embodiment, the application of a pure silk fibroin 3D printing scaffold in 3D bioprinting bone defect materials is provided, including:

[0063] The pure silk fibroin gel scaffold prepared in Example 2 was frozen at -20°C for four to five hours, and then placed in a freezer at -80°C for overnight freeze-drying to obtain pure silk fibroin 3D printing Freeze-dried scaffolds.

[0064] Using scanning electron microscope (SEM) to observe the above-prepared 3D printed scaffold, the freeze-dried scaffold has a micron-scale microporous structure inside, and its structure is detailed in Figure 6 .

[0065] The 3D printing scaffold prepared above was used for in vitro cell culture. The cultured cells were pre-osteoblast MC3T3 cells, and the cultured cells were labeled with fluorescent proteins. Figure 7 It is the confocal image of the 7th day of cell culture. It can be seen from the figure that a large amount of fluorescence is displayed inside and on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com