A kind of preparation method of high-purity copper rotating target

A high-purity copper, rotating target technology, applied in the field of rotating targets, can solve the problems of easy deformation, poor rigidity, low material strength, etc., to meet the needs of use, improve stability, and avoid the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

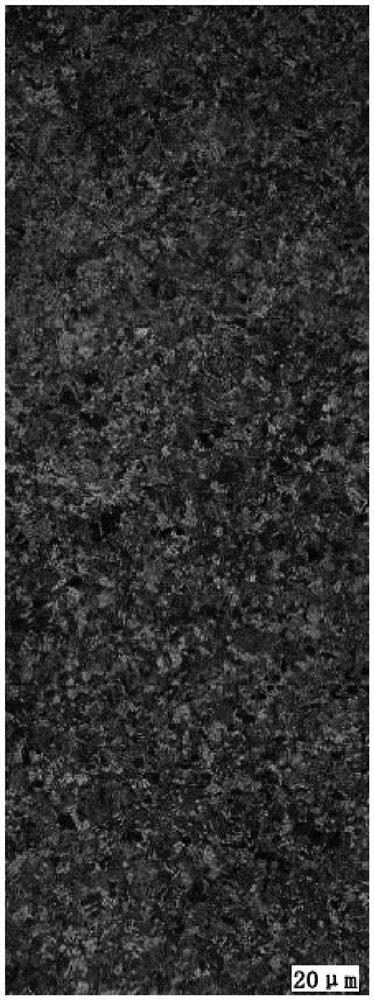

Image

Examples

Embodiment Construction

[0045] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0046] A method for preparing a high-purity copper rotating target, comprising the following steps:

[0047] 1) Ingot pretreatment step: heat and heat-preserve the high-purity copper round ingot, then upsetting, so that the high-purity copper round ingot forms a high-purity copper ingot, and rounds and elongates the high-purity copper ingot to form a round ingot , the round ingot is subjected to preliminary machining to obtain a pretreated copper ingot of a set size; preliminary machining refers to removing the scale of the round ingot and the two ends of the round ingot, including the following sub-steps:

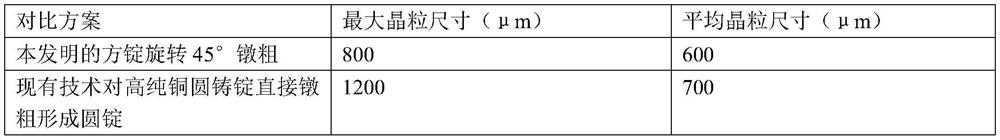

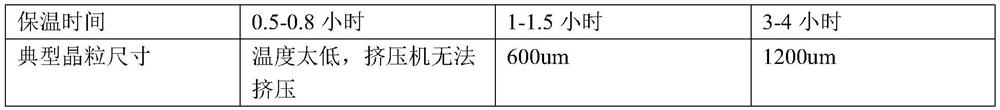

[0048] 1.1) One upsetting sub-step, the high-purity copper round ingot is subjected to three-way forging to obtain a primary square ingot, so that the side length of the primary square ingot is increased by 15% to 20% com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com