Clothing fabric batch dyeing equipment

A kind of dyeing equipment and fabric technology, which is applied in the field of clothing fabric dyeing, can solve the problems of large quantities, laborious operation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

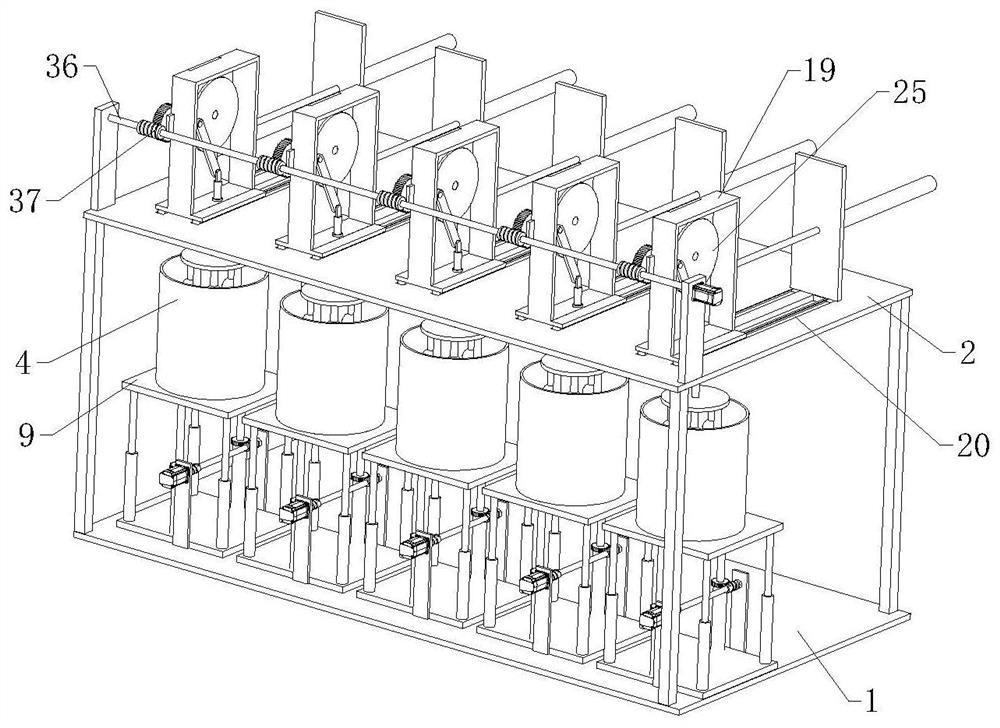

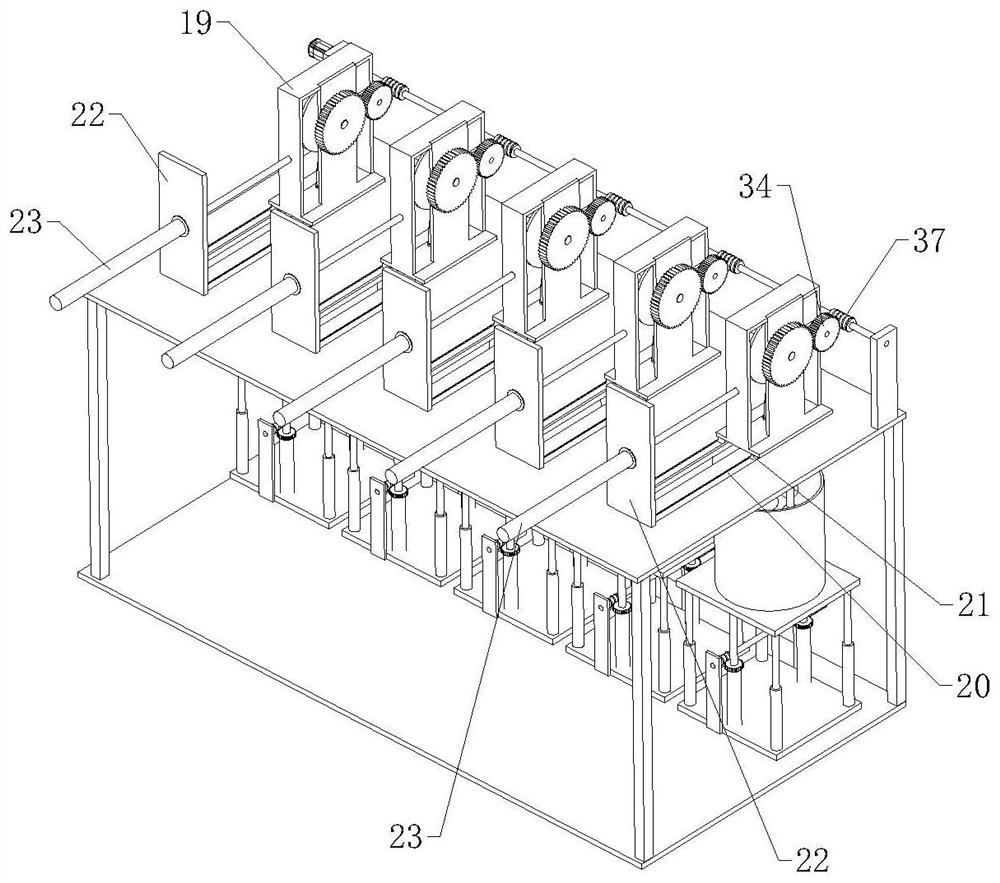

[0065] refer to Figure 1 to Figure 10 Shown, a kind of garment fabric batch dyeing equipment, comprises:

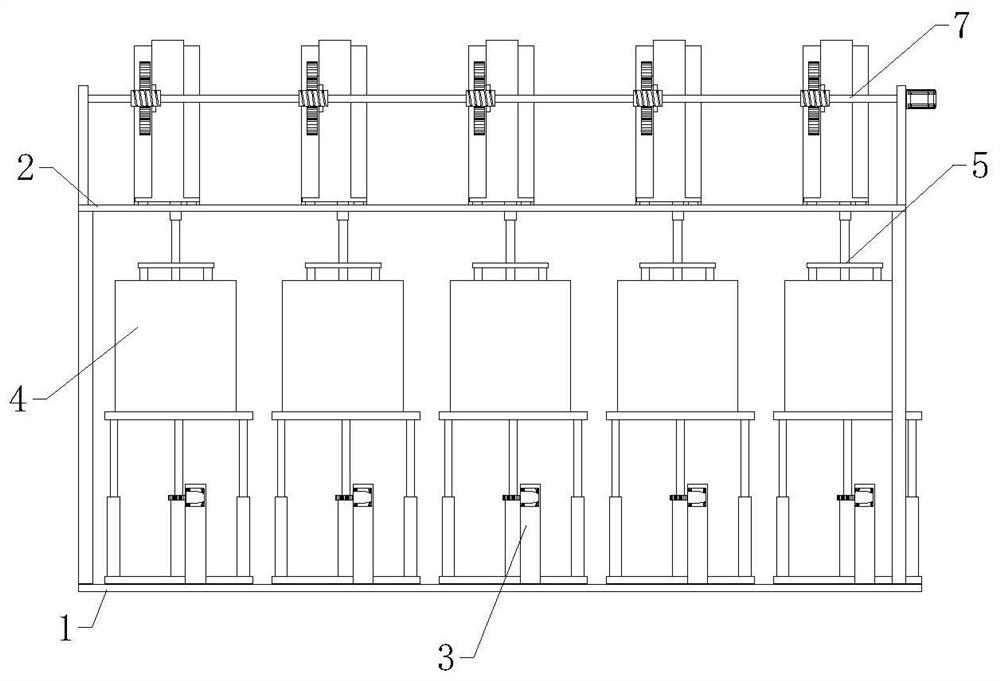

[0066] bottom plate 1;

[0067] The top plate 2 is located directly above the bottom plate 1, and each corner of the top plate is installed on the top of the bottom plate 1 through support columns;

[0068] There are a plurality of lifting mechanisms 3, which are equidistantly distributed on the top of the bottom plate 1 along the length direction of the bottom plate 1;

[0069] Dyeing cylinder 4, its quantity is identical with the quantity of lifting mechanism 3 and is placed on each top plate 2 correspondingly one by one;

[0070] Press-in mechanism 5, its quantity is the same as the quantity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com