Grounding rod

A technology of grounding rods and grounding devices, which is applied in the direction of connecting contact materials, etc., can solve the problems of long time for grounding operations, grounding resistance that is not as high as the grounding resistance requirements, and difficult operations, so as to improve efficiency, improve soil quality, chip rate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

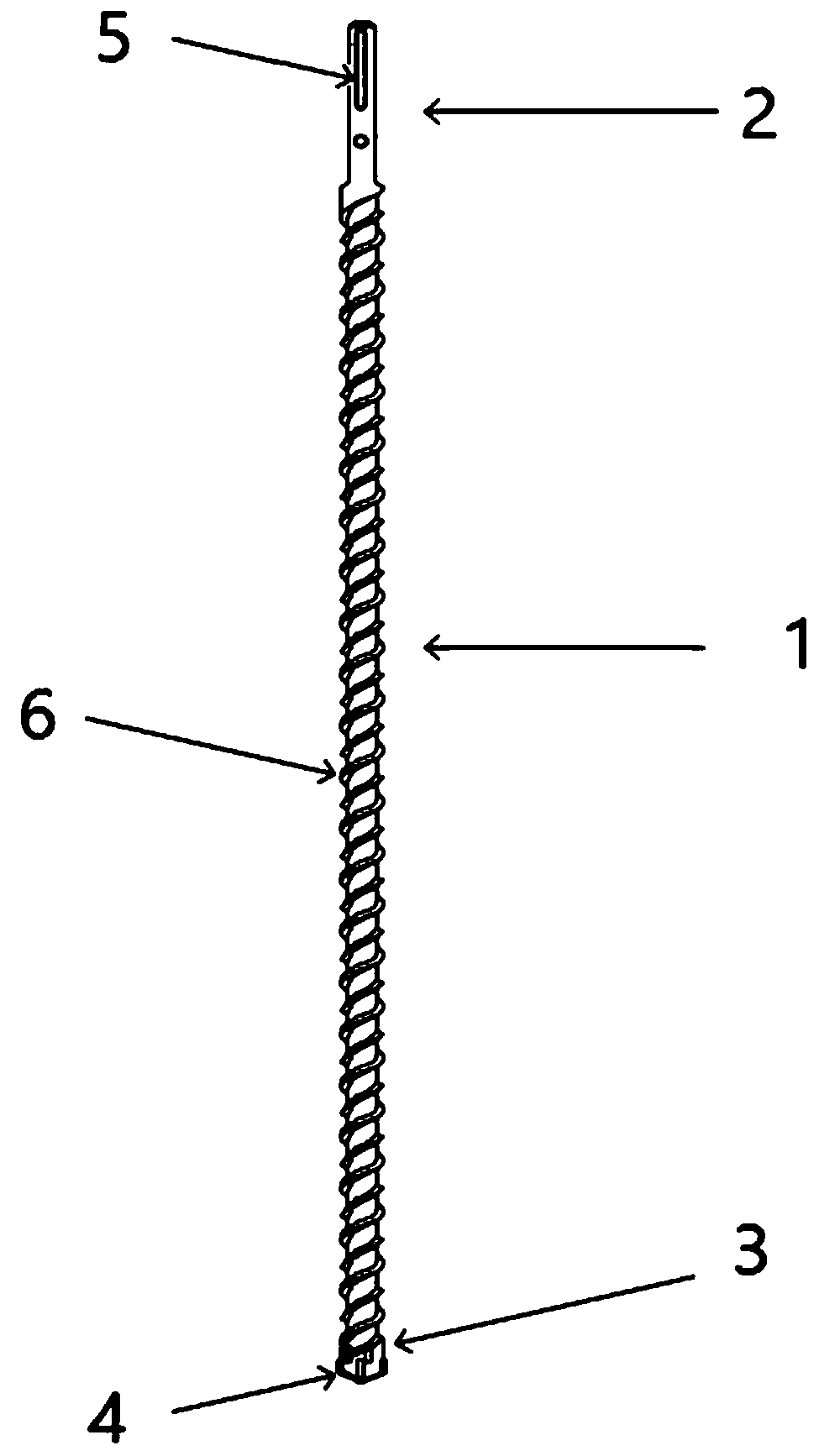

[0027] Such as figure 1 As shown, the present invention relates to a ground rod, which includes a ground rod handle 2 , a ground rod body 1 and a ground rod head 3 . The top of the ground rod body 1 is connected to the ground rod handle 2, and the bottom of the ground rod body 1 is connected to the ground rod head 3, and the three are integrally formed.

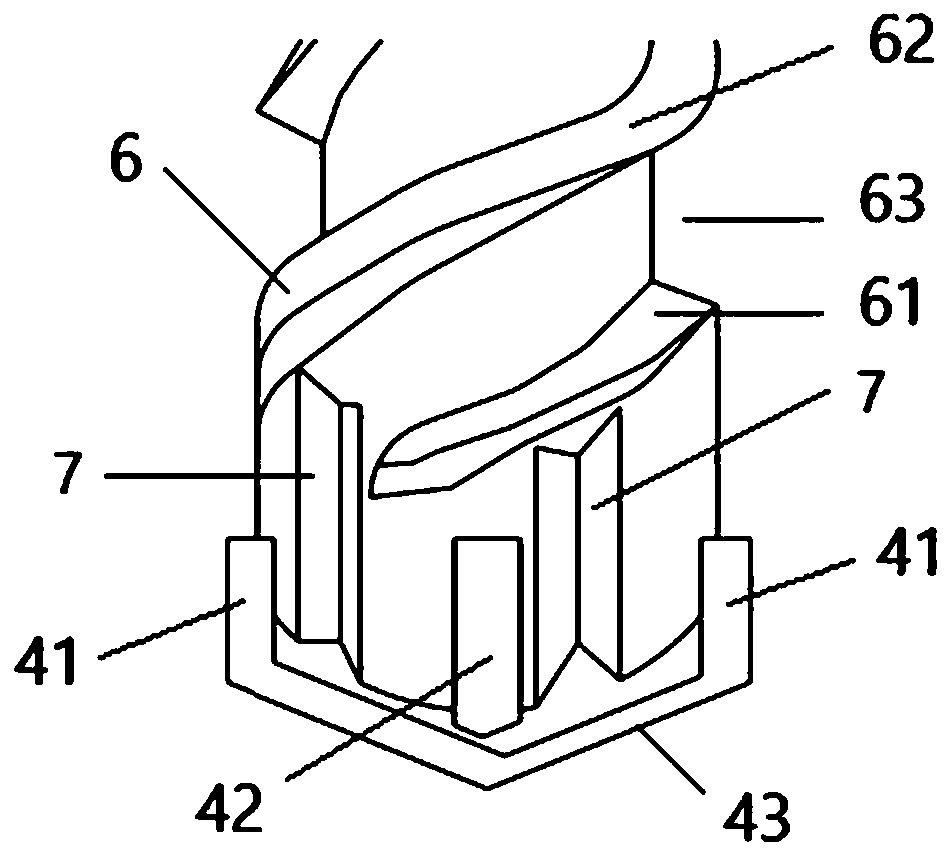

[0028] The grounding rod body 1 is made of special steel rod, which has the characteristics of high hardness, not easily deformed, corrosion resistance and wear resistance. The ground rod body 1 is provided with a protruding spiral texture 6, which is an optimal design after comprehensive verification of a large number of soil properties and chip yield. The spiral texture includes coarse threads 61 and fine threads 62 arranged in sequence, and grooves between adjacent spiral texture tracks form chip removal grooves 63 for discharging soil debris when grounding.

[0029] The ground rod head 3 is arranged at one end of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com