A single-layer cross-coupled filter

A cross-coupling and filter technology, which is applied in the field of filters, can solve problems affecting filter performance and height increase, and achieve the effects of improving design flexibility, reducing processing and assembly costs, and reducing processing and assembly tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

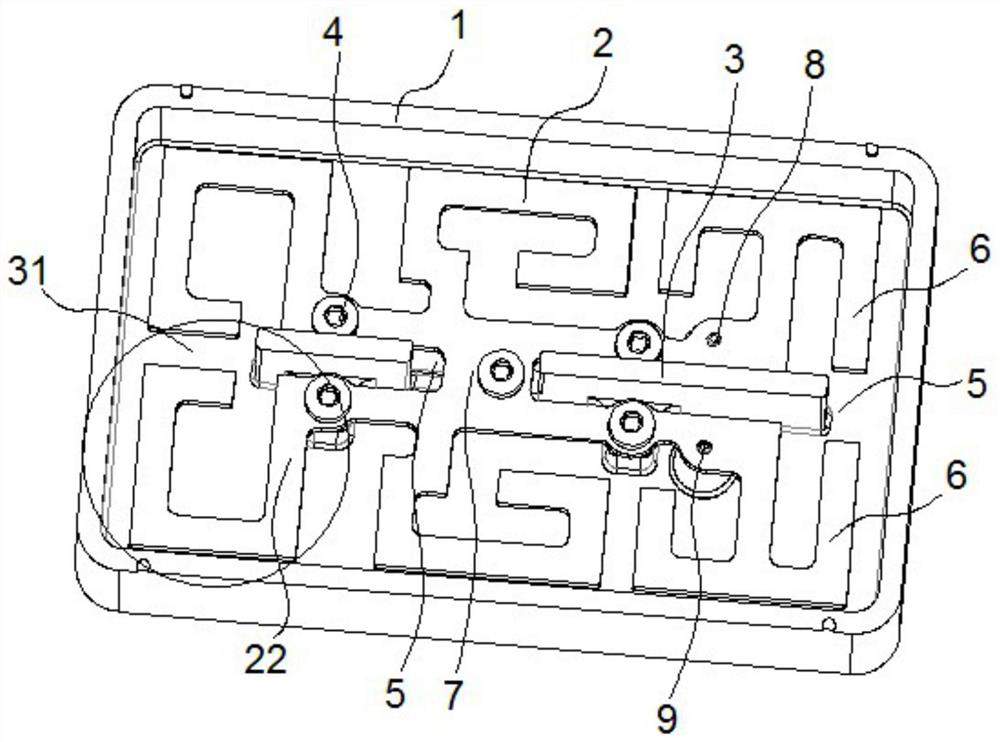

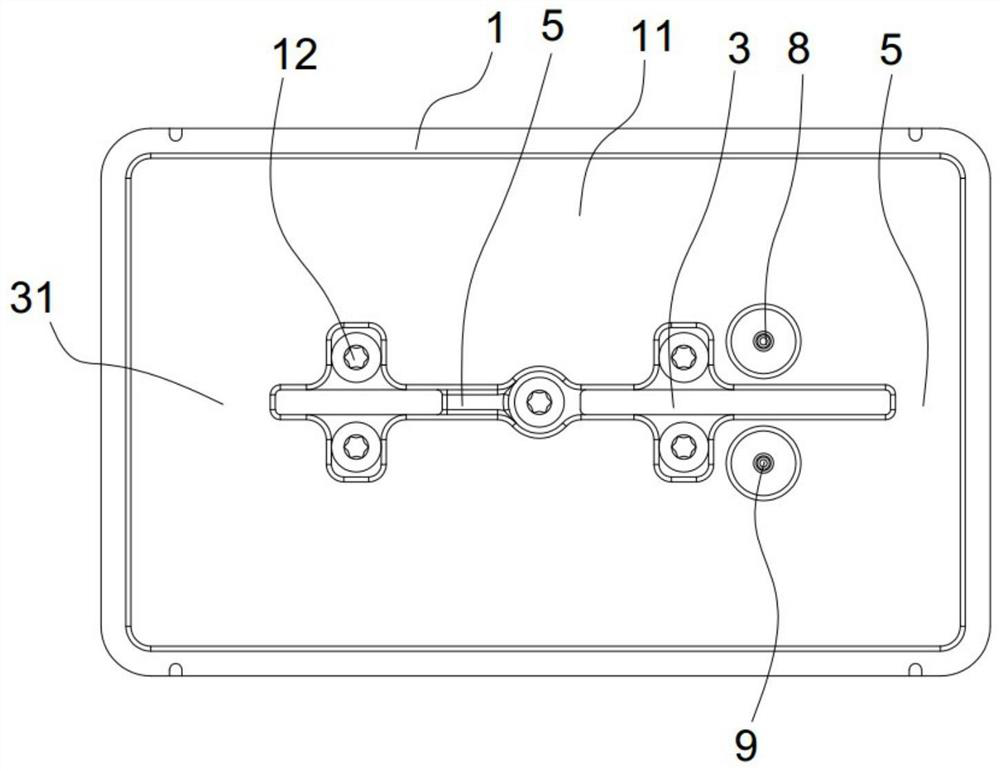

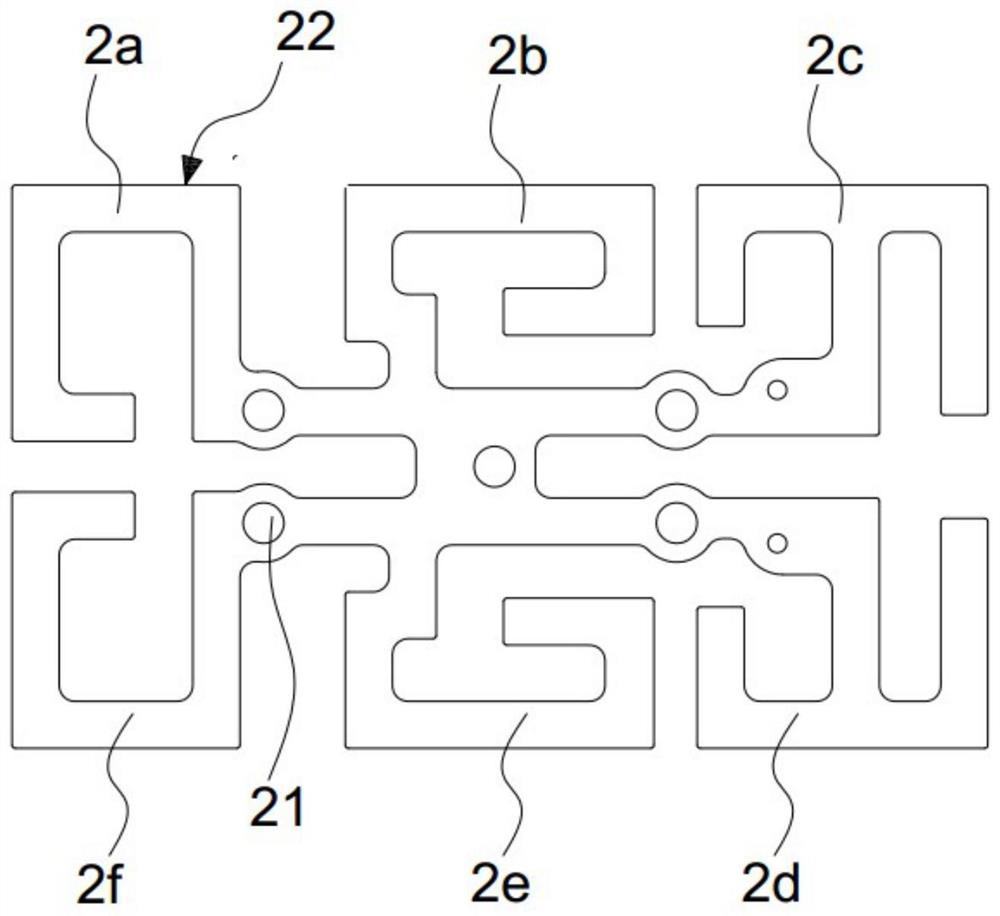

[0034] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0035] A single-layer cross-coupled filter disclosed by the present invention, through the improved design of the resonator shape, a single-layer resonant unit structure composed of the resonator is integrally formed, and non-adjacent parts of the single-layer resonant unit structure Adding cross-coupling between resonators can realize the miniaturization of the filter at the same time: 1. There is no need to add additional conductors to achieve cross-coupling, which reduces processing and assembly costs, as well as processing and assembly tolerances; 2. In non-phase The cross-coupling between adjacent resonators can be controlled separately, so the design and manufacture become simple; 3. Compared with the multi-layer structure, the single-layer cross-coupling reduces the overall heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com