Radio frequency chip integrated packaging structure and producing method thereof

A technology of integrated packaging and radio frequency chips, applied in antenna support/mounting devices, semiconductor/solid-state device manufacturing, antennas, etc., can solve problems such as complex processes, inability to integrate antennas, difficulty in packaging radio frequency chips and antennas, etc., and achieve simple process , Reduce the size of the package, and improve the high-frequency electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

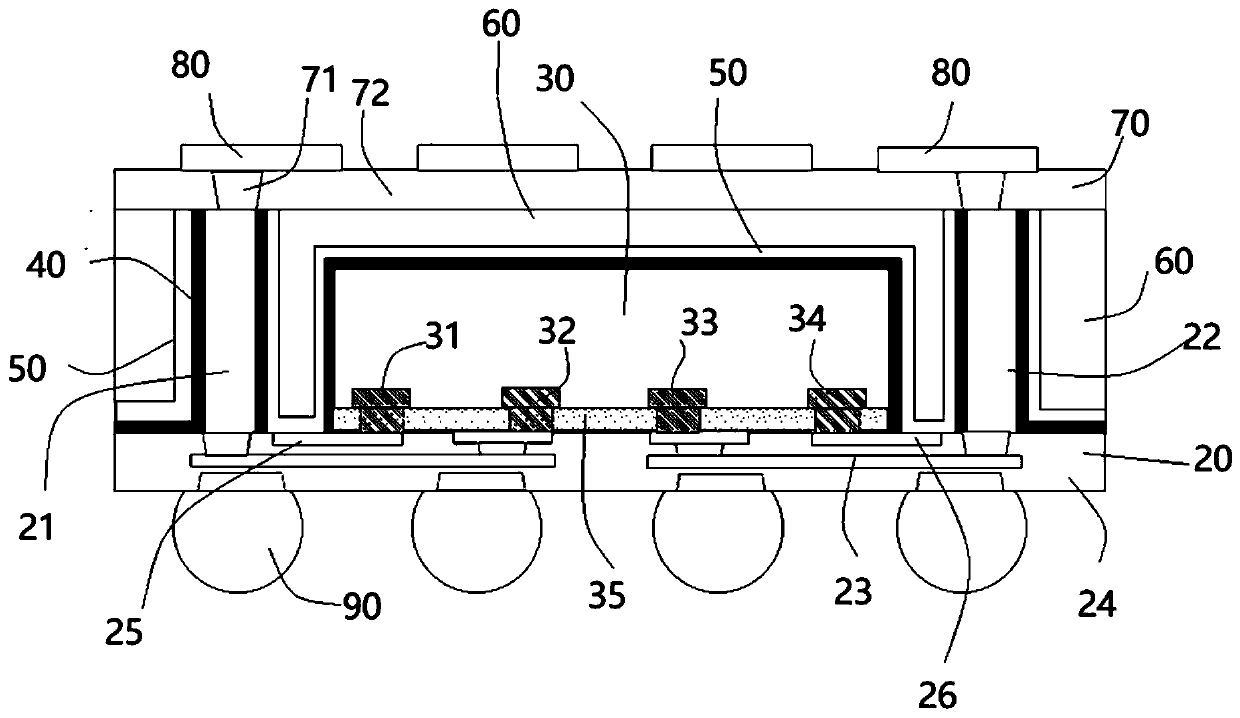

[0065] This embodiment also provides a radio frequency chip integrated packaging structure, such as figure 1 As shown, the integrated package structure of the radio frequency chip includes: a first conductive layer 20; one or more conductive columns (such as figure 1 As shown, the example is the first conductive column 21 and the second conductive column 22), which stand on the first conductive layer 20; the radio frequency chip 30 is attached (for example, bonded) on the first conductive layer 20, The radio frequency chip 30 is located between the first conductive column 21 and the second conductive column 22; the grounding parts 25 and 26 of the shielding layer are located between the first conductive column 21, the second conductive column 22 and the On the first conductive layer 20 between the radio frequency chips 30; the insulating film 40 covers the radio frequency chip 30, the sides of the first conductive pillars 21 and the sides of the second conductive pillars 22, a...

Embodiment 2

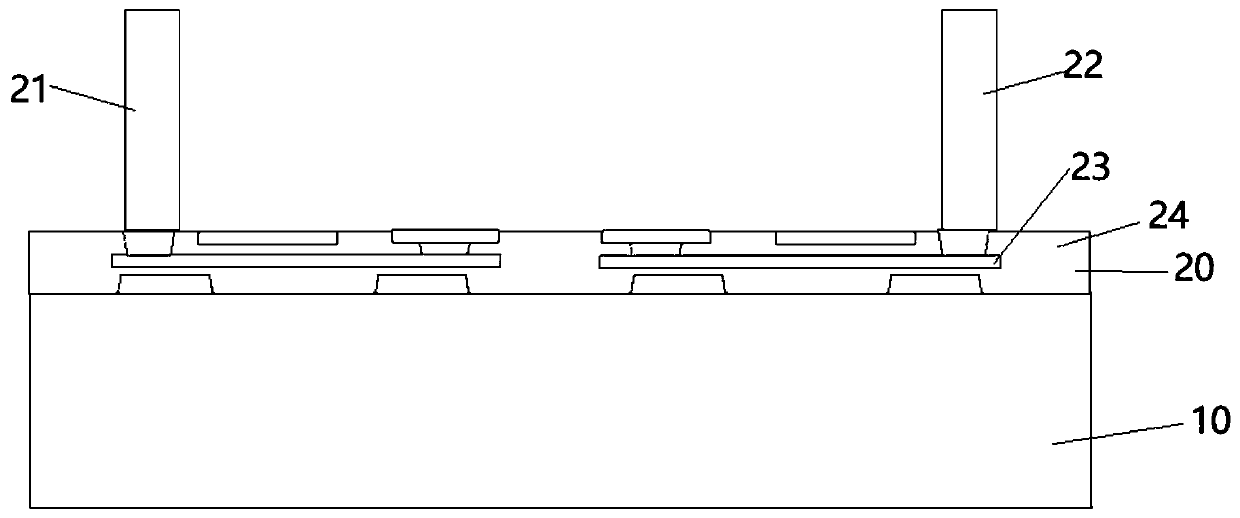

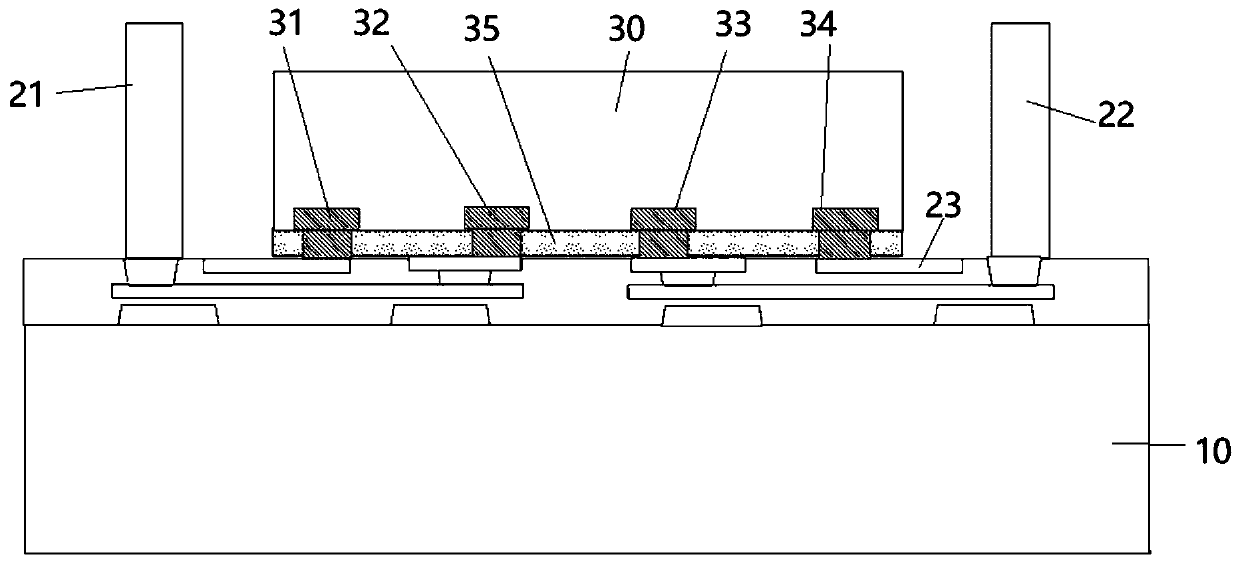

[0073] This embodiment provides the preparation method of the radio frequency chip integrated packaging structure in the previous embodiment, such as Figure 2-9As shown, the preparation method of the radio frequency chip integrated package structure includes: providing a temporary bonding carrier 10, forming a first conductive layer 20 on the first surface of the temporary bonding carrier 10, and forming a first conductive layer 20 on the first conductive layer Form the first conductive column 21 and the second conductive column 22 on the 20; attach the radio frequency chip 30 to the first conductive layer 20, the radio frequency chip 30 is located on the first conductive column 21 and the second conductive layer between the pillars 22; form an insulating film 40, the insulating film 40 covers the first conductive layer 20, the radio frequency chip 30, the first conductive pillar 21 and the second conductive pillar 22; remove the first conductive pillar Part of the insulating...

Embodiment 3

[0086] This embodiment provides the preparation method of the radio frequency chip integrated packaging structure in the previous embodiment, such as Figure 10 As shown, in the preparation method of the radio frequency chip integrated packaging structure described in the previous embodiment, arranging the antenna array 80 on the second conductive layer 70 includes: arranging the first antenna array on the second conductive layer 70 81, forming an antenna plastic layer 83, the antenna plastic layer 83 covers the first antenna array 81, and adopts a compression molding process, a transfer molding process, a liquid sealing molding process, a vacuum lamination process, or a spin coating process to form the antenna Plastic sealing layer 83 ; the material of the antenna plastic sealing layer 83 may include one of polyimide, silica gel, and epoxy resin. The plastic sealing layer of the antenna may also include one or more of low dielectric constant materials such as polytetrafluoroe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com