Composite material propeller layering angle optimization method based on multi-objective genetic algorithm

A multi-objective genetic and composite material technology, applied in the fields of genetic law, design optimization/simulation, calculation, etc., can solve the problems of relying on finite element software, lack of versatility, and large amount of calculation, so as to meet the requirements of flexible search process and objective function. low, the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

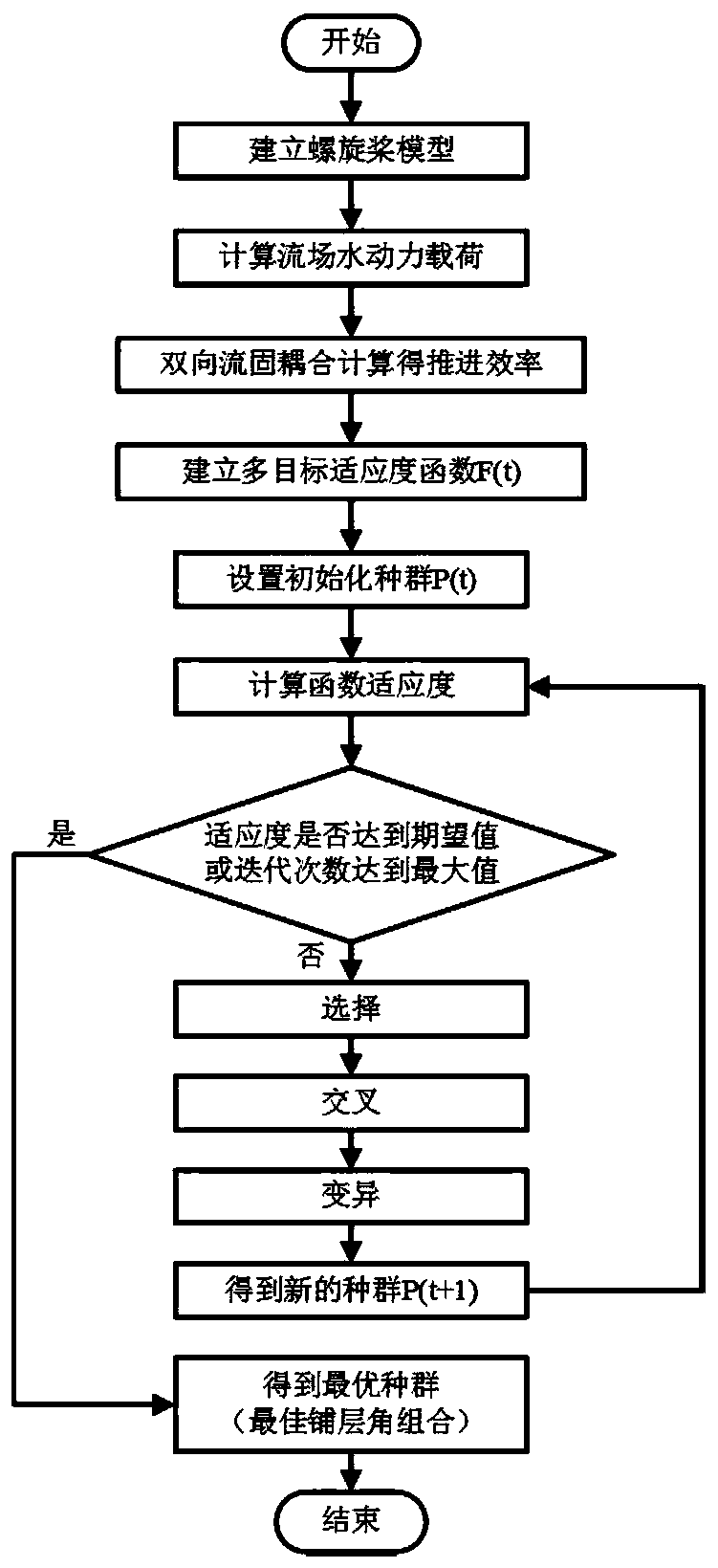

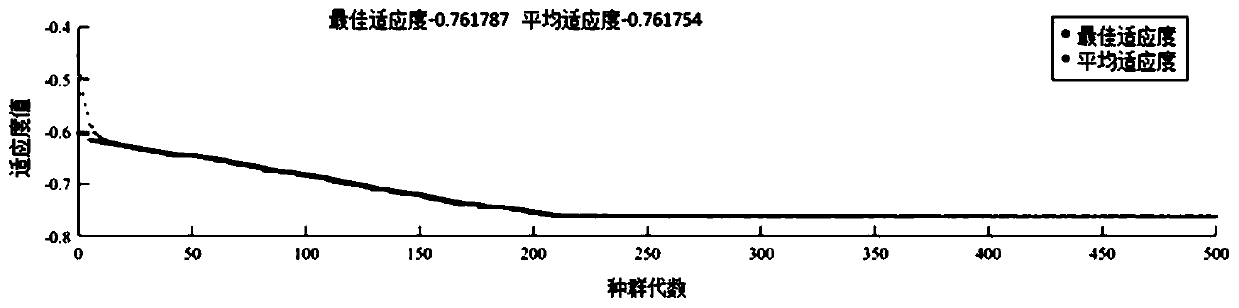

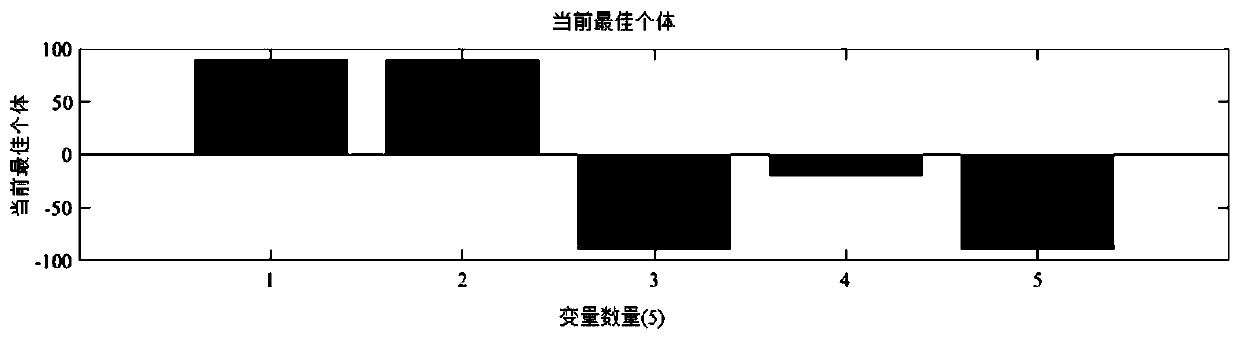

[0031] Take the SEIUN-MARU high-slope ship propeller (HSP) as an example, such as Figure 1-3 As shown, the method for optimizing the ply angle of the fiber composite marine propeller disclosed in this embodiment, the specific implementation steps are as follows:

[0032] Step 1: Establish a composite material propeller model based on the ACP module in the selected WorkBench platform, define the angles of each layer of the composite material laminate with the middle surface of the metal propeller blade as the symmetry center to complete the fiber composite material layup, and import the pressure of the metal propeller blade The surface and suction surface models are used to constrain the shape of the composite material layup, and finally the establishment of the finite element model of the composite material propeller is realized.

[0033] The fiber composite lay-up method includes unidirectional or braided lay-up method.

[0034] Step 2: Import the finite element model of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com