Device and method for disposing industrial waste through multi-stage air flow sorting fixed bed

A technology of airflow separation and industrial waste, which is applied in the direction of separating solids from solids with airflow, combustion methods, chemical instruments and methods, etc., and can solve the problems of single disposal of waste, small amount of disposal, incomplete treatment, etc. To achieve thorough treatment, reduce pollution, and deal with the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

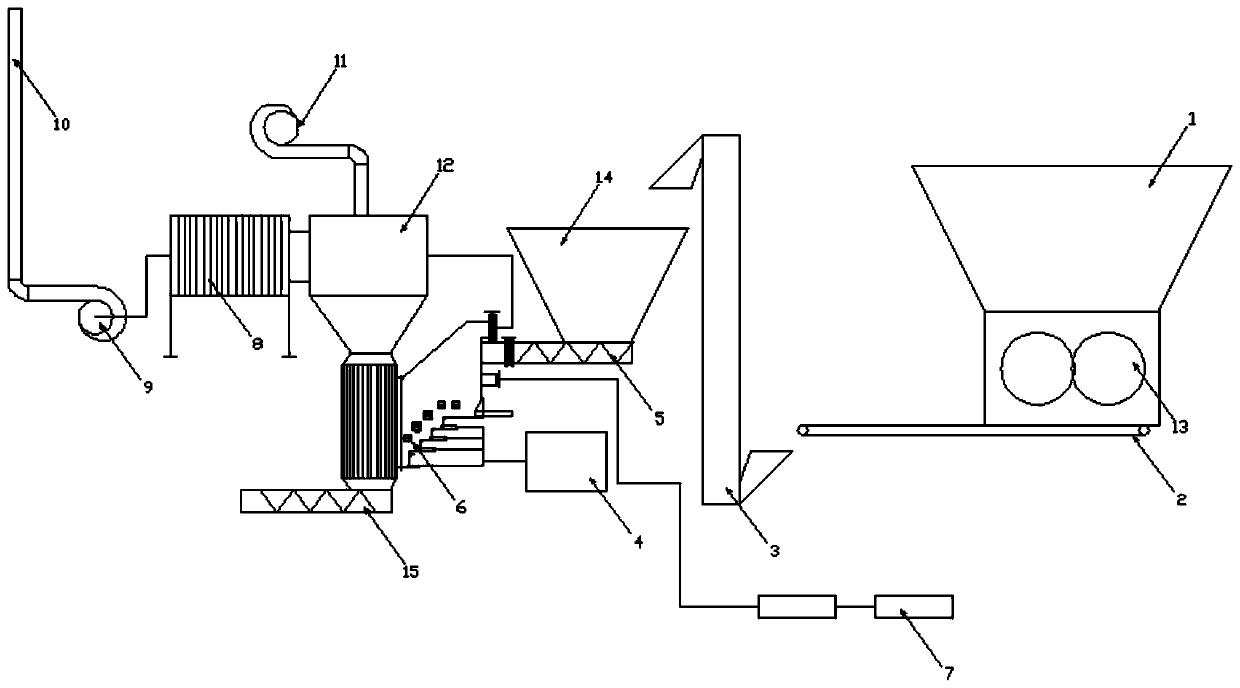

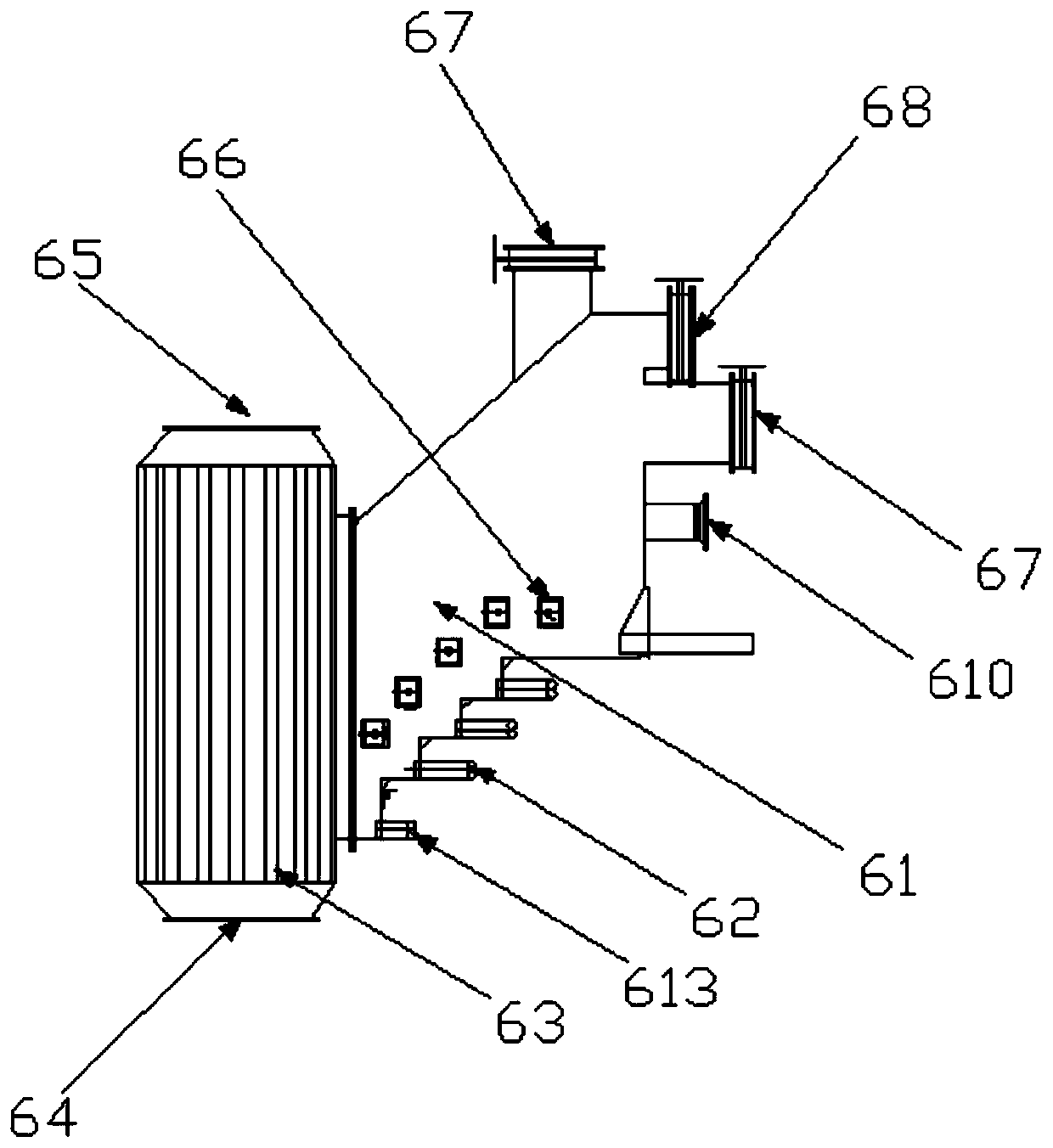

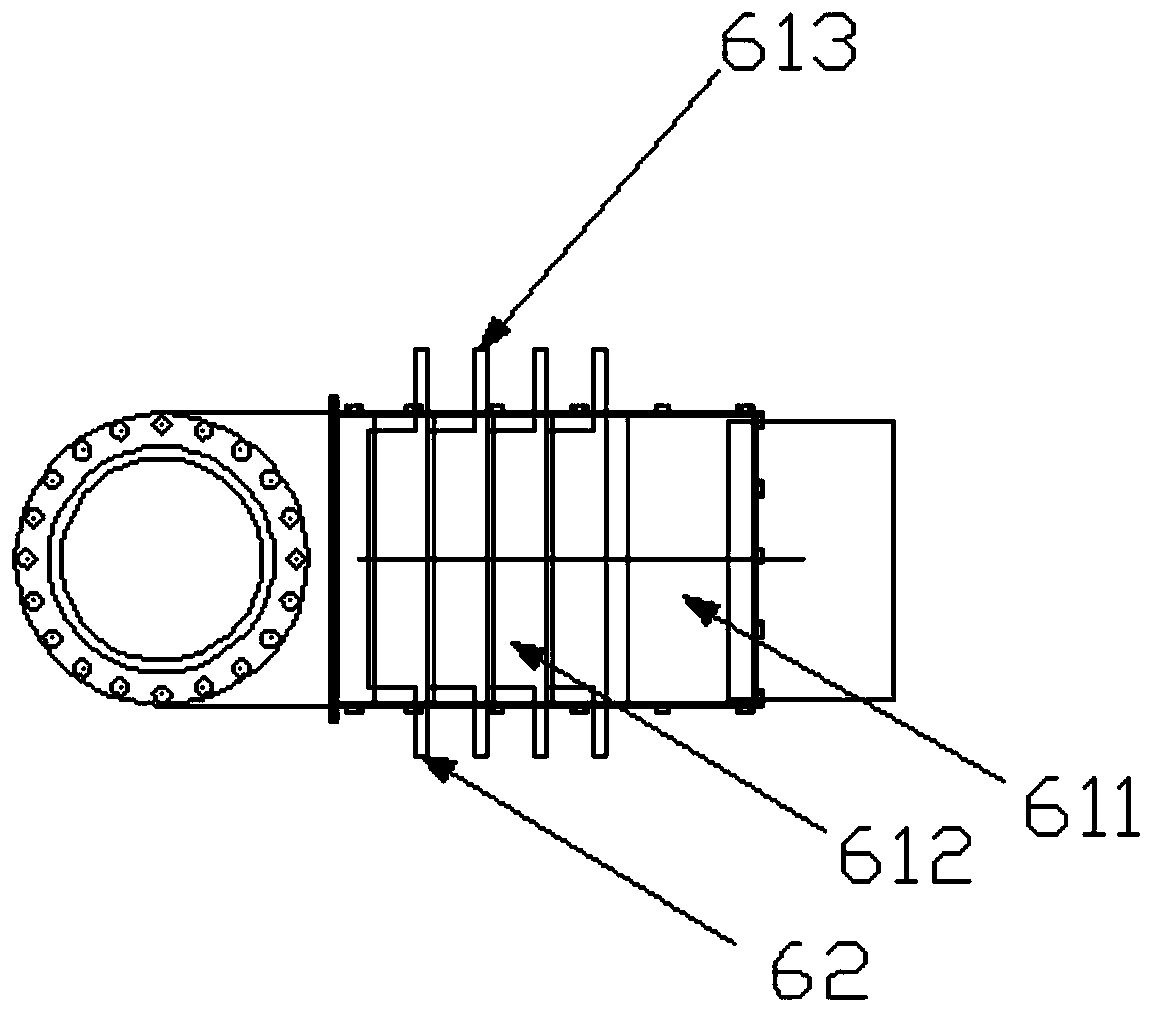

[0022] Such as figure 1 , figure 2 , image 3 As shown, a device for disposing of industrial waste using a multi-stage airflow sorting fixed bed in this embodiment includes an industrial waste storage bin 1, a crushing and mixing device 13, a conveying device 2 and a fuel storage bin 14, and the crushing and mixing device 13 can directly Use the pulverizer that buys on the market, conveying equipment 2 can use existing conveyer belt; Above, the other end of the conveying equipment 2 is located above the fuel storage bin 14 for transporting the crushed industrial waste into the fuel storage bin 14; it also includes: a screw feeder 5, a multi-stage airflow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com