High-definition anti-fog coating

An anti-fog coating, high-definition technology, used in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of fogging of helmet lenses and goggles, affecting drivers or indoor personnel, and easy-to-crack window glass curtains. fog and other problems, to achieve the effect of excellent anti-fog performance, high light transmission performance, and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides the preparation method of this high-definition anti-fog coating, and it comprises the following steps:

[0037] 1) The solvent is divided into four parts: the first part of solvent, the second part of solvent, the third part of solvent and the fourth part of solvent;

[0038] 2) Stir and dissolve the methallyl ether, polyester acrylic monomer, and polyurethane-modified acrylic resin prepolymer with the first solvent at 65-120° C. for 1-3 hours, and then lower the temperature to 40° C. -55 ℃, and keep warm, obtain the first mixture;

[0039] Stirring and dissolving the tetraethylamine perfluorooctane sulfonate and sodium 3-prop-2-enoyloxypropane-1-sulfonate with the second solvent for 15-60 minutes to obtain a second mixture;

[0040] adding nano-copper, nano-titanium dioxide, and nano-alumina to the third solvent, and stirring for 15-60 minutes to obtain a third mixture;

[0041] adding the coupling agent and the leveling agent to t...

Embodiment 1

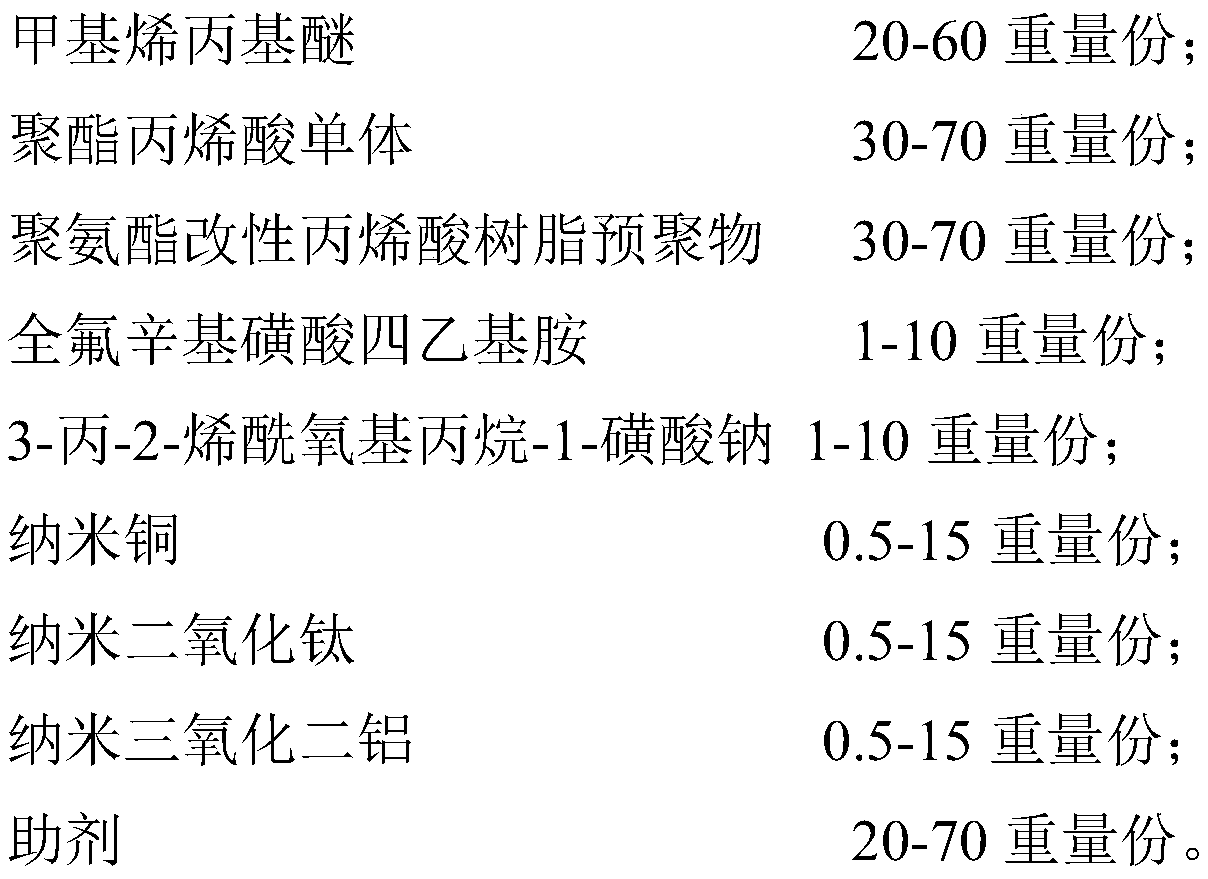

[0047] A high-definition anti-fog coating, which includes the following raw materials in parts by weight:

[0048]

[0049] Wherein, the auxiliary agent includes 2 parts by weight of leveling agent, 3 parts by weight of coupling agent, 3 parts by weight of curing agent and 52 parts by weight of solvent. The leveling agent is a mixture of a fluorine-modified acrylic leveling agent and an organically modified polysiloxane. The coupling agent is a mixture of glycidyl ether silane and vinyl silane. The curing agent is diaminocyclohexane. The solvent is isopropanol.

[0050] The preparation method of this high-definition anti-fog coating, it may further comprise the steps:

[0051] 1) The solvent is divided into four parts: the first part of solvent, the second part of solvent, the third part of solvent and the fourth part of solvent;

[0052] 2) Stir and dissolve the methallyl ether, polyester acrylic monomer, and polyurethane-modified acrylic resin prepolymer with the firs...

Embodiment 2

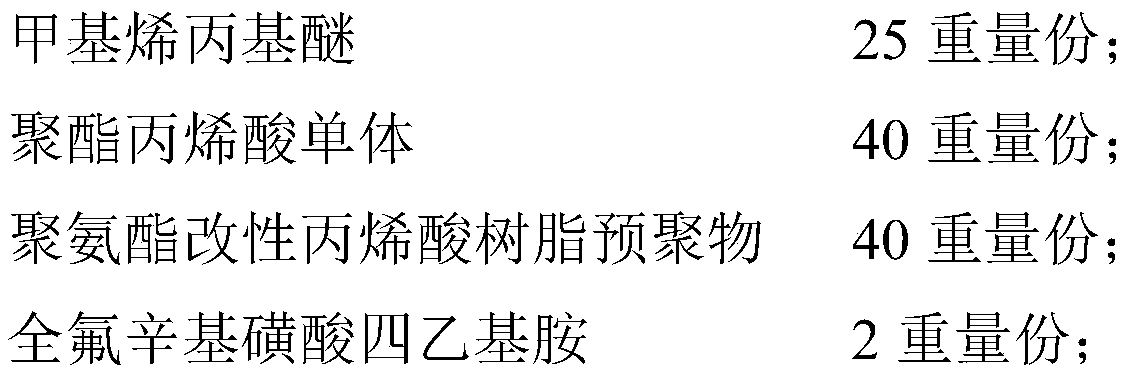

[0059] The difference with embodiment 1 is only that the content of each component is different, specifically:

[0060] The high-definition anti-fog coating includes the following raw materials in parts by weight:

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com