Positive electrode active material, positive electrode plate and sodium ion battery

A positive electrode active material and positive electrode sheet technology, applied in the direction of active material electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor actual capacity and cycle performance, hinder the commercialization of sodium-ion batteries, etc., and achieve high charge and discharge The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Next, a preparation method of the positive electrode active material in the present application will be described. According to this preparation method, the above-mentioned cathode active material can be obtained. The preparation method comprises the following steps:

[0046] S10. Add copper salt, iron salt, manganese salt and optional salt containing M element into the solvent according to the stoichiometric ratio to prepare a mixed solution.

[0047] S20, adding a precipitating agent and a complexing agent into the mixed solution to obtain a reaction solution, and adjusting the pH value of the reaction solution within a predetermined range.

[0048] S30, make the reaction solution carry out co-precipitation reaction at a predetermined temperature and stirring rate, separate and collect the obtained co-precipitation product, wash the precipitation product several times with an appropriate amount of solvent, and dry at a predetermined temperature to obtain the transiti...

Embodiment 1

[0098] Preparation of cathode active material

[0099] S10. According to the stoichiometric ratio, copper sulfate, ferrous sulfate and manganese sulfate are dissolved in deionized water under the protection of an inert atmosphere to prepare a mixed solution, wherein the total concentration of metal ions is 1.5 mol / L.

[0100] S21. Disperse the precipitating agent sodium hydroxide in deionized water to prepare a precipitating agent solution, wherein the concentration of sodium hydroxide is 4 mol / L. Ammonia water with a concentration of 1mol / L was used as complexing agent solution.

[0101] S22. Add the precipitating agent solution and the complexing agent solution to the mixed solution to obtain a reaction solution, and control the pH value of the reaction solution to 11.2.

[0102] S30, making the reaction solution react at 60°C and a stirring rate of 800rpm for 30h, separating and collecting the obtained coprecipitated product, washing the precipitated product several time...

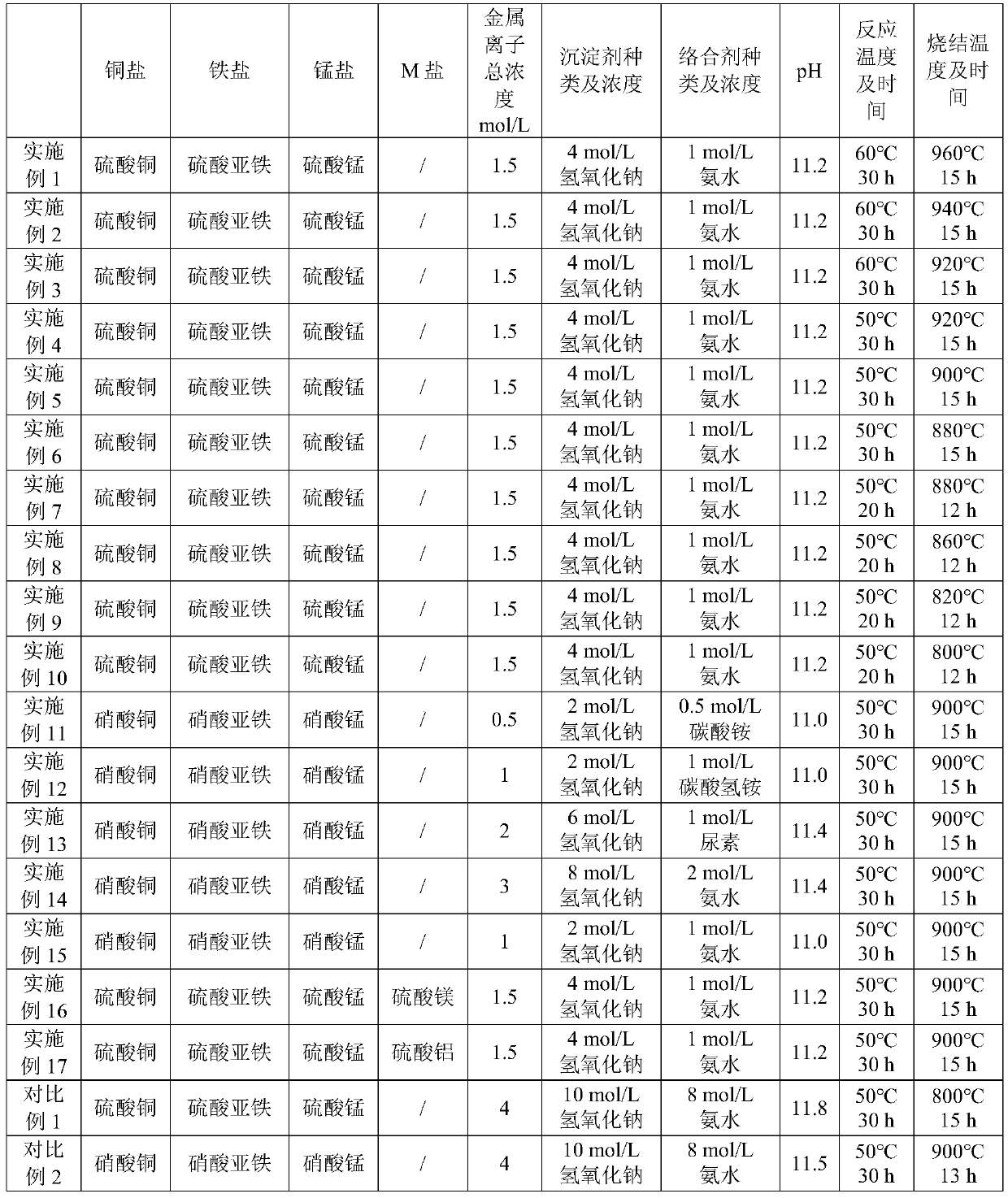

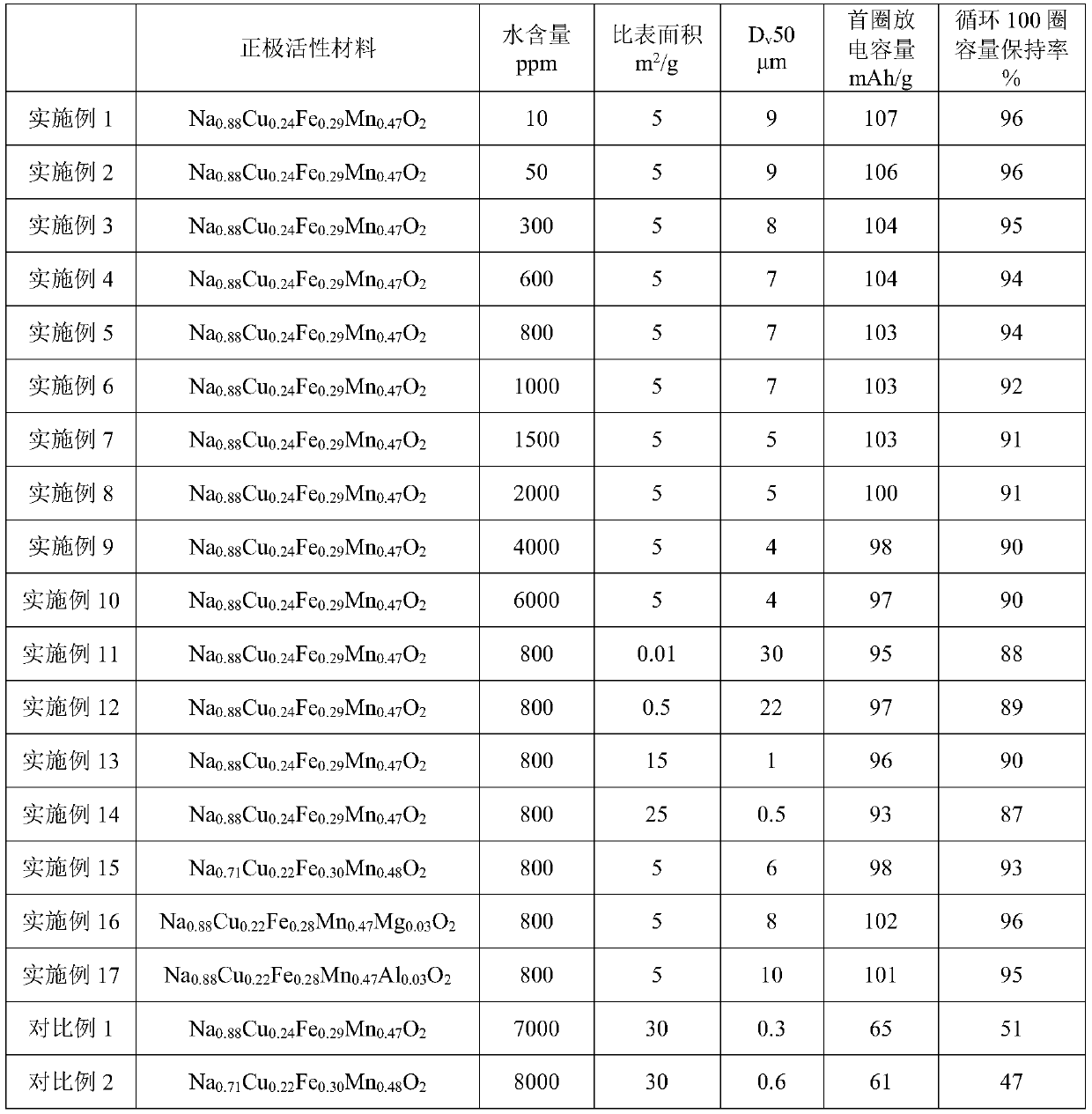

Embodiment 2~17 and comparative example 1

[0114] Similar to Example 1, the difference is that the reaction parameters in the preparation step of the positive electrode active material were adjusted. The specific parameters are detailed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com