Polyurethane elastic fiber and wound body thereof

A polyurethane elastic and fiber technology, applied in the direction of single-component polyurethane artificial filament, fiber type, fiber treatment, etc., can solve the problems of small tension change, not easy to loose hair, broken ends, etc., to achieve small tension change, not easy to loose hair, The effect of suppressing decapitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

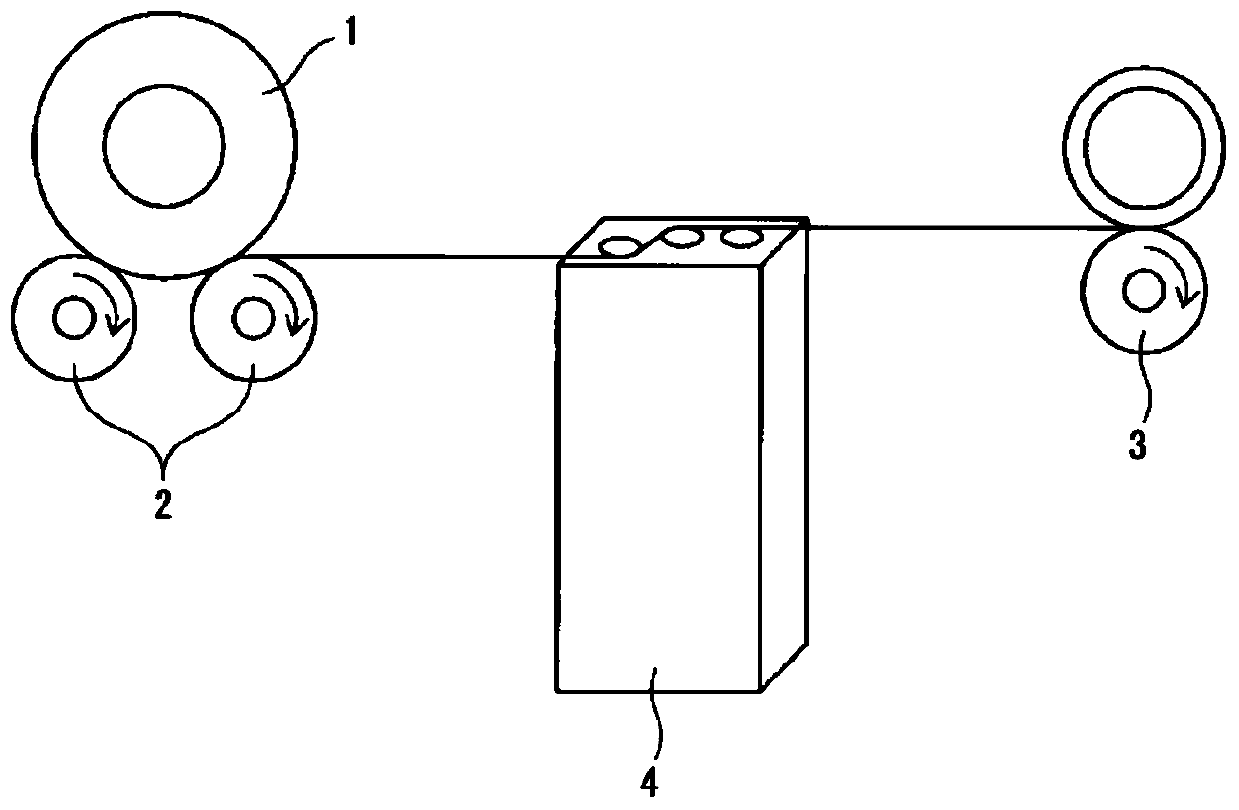

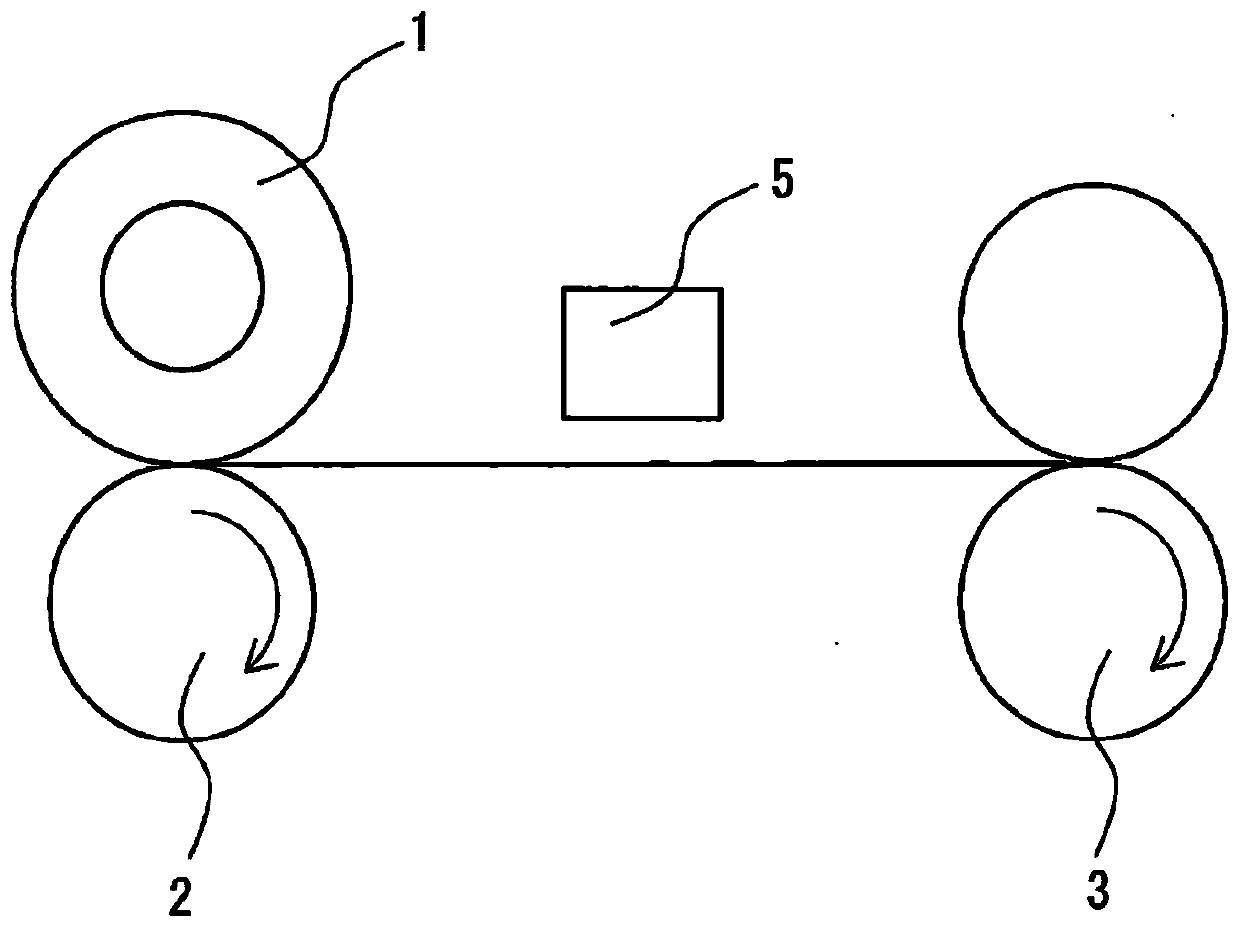

Method used

Image

Examples

Embodiment 1~8

[0214] Diethylene glycol dibenzoate (manufactured by Tokyo Chemical Industry Co., Ltd.: there is an aromatic ring in the compound) is contained in the oil agent or in the polymer so that the total weight of the polyurethane elastic fiber becomes 200ppm, and the diameter of the single filament is The ratio of the maximum value to the minimum value is 1.47 to 1.53, and the outflow initiation temperature is above 200°C. Under the condition that no urethane or urea compound containing tertiary amine is contained, the elongation is 2%, as follows The polyurethane elastic yarn wound bodies of Examples 1 to 8 were produced by changing the yarn fineness and the number of filaments as shown in Table 1. The results are shown in Table 1 below.

Embodiment 9~15

[0216] The yarn fineness is 620dtex, the number of filaments is 72, the ratio of the maximum value to the minimum value of the single filament diameter is 1.48 to 1.56, and the elongation is 2%, and the oil agent or polymer is changed as shown in the following Table 1. The content ratio of diethylene glycol dibenzoate (manufactured by Tokyo Chemical Industry Co., Ltd.: there is an aromatic ring in the compound) contained in the polyurethane elastic fiber relative to the total weight of the polyurethane elastic fiber and the outflow start temperature, when the amino group containing the tertiary amine is not contained The polyurethane elastic yarn wound bodies of Examples 9 to 15 were produced under the condition of formate ester or urea compound containing tertiary amine.

[0217] It was found that the polyester elastic fiber contained the ester or the phosphoric acid ester, thereby suppressing the breakage during processing. The results are shown in Table 1 below.

[0218] [...

Embodiment 16~21

[0221] The yarn fineness is 620dtex, the number of filaments is 72, and the oil agent contains ester or phosphoric acid ester so that the total weight of the polyurethane elastic fiber is 200ppm, and the ratio of the maximum value to the minimum value of the monofilament diameter is 1.46 to 1.53 , The outflow initiation temperature is 200°C or higher, under the condition that no urethane containing tertiary amine or urea compound containing tertiary amine is contained, the elongation is 2%, and the ester is changed as shown in Table 2 below. or phosphoric acid ester to manufacture the polyurethane elastic yarn wound bodies of Examples 16-21. As the ester or phosphoric acid ester, methyl benzoate (manufactured by Tokyo Chemical Industry Co., Ltd.: an aromatic ring is present in the compound), benzyl benzoate (manufactured by Tokyo Chemical Industry Co., Ltd.: an aromatic ring is present in the compound), trimellitic acid tris Methyl ester (manufactured by Tokyo Chemical Industr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com