Fibre sand filtering material

A fiber and sand filter technology, which is applied in the field of fiber sand filter materials, can solve the problems that the fibers cannot be cleaned, affect the use of customers, and output attenuation, etc., so that the fibers can not fall off, the consolidation is firm, easy to clean, and the water head loss is small. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

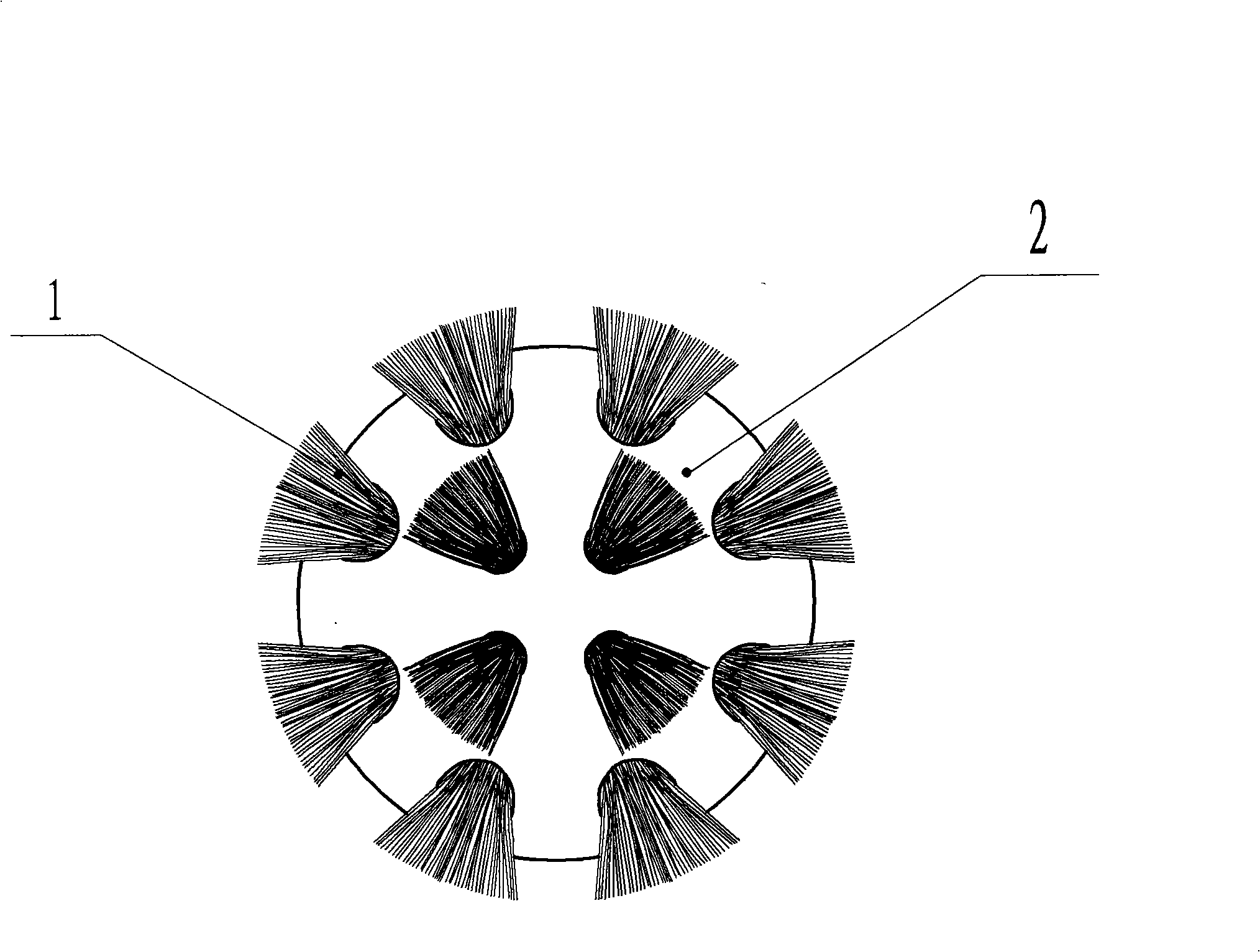

[0012] Embodiment 1: fiber sand filter material, by a plurality of skeins of fiber silk filter material 1 intersecting at one point in multiple directions in space, the diameter of every skein of fiber silk filter material 1 is φ 2mm, after synthetic resin is melted with electric heating method at intersection point Each strand of fiber filter material 1 is firmly fused together to form a sand-like core 2, the diameter of the sand-like core 2 is φ0.4 mm, and each strand of fiber filter material 1 is 2 mm higher than the outer surface of the sand-like core 2.

Embodiment 2

[0013] Embodiment 2: fiber sand filter material, by a plurality of skeins of fiber silk filter material 1 intersecting at one point in space, the diameter of every skein of fiber silk filter material 1 is φ 5mm, after the synthetic resin is melted by electric heating method at the intersection point Each strand of fiber filter material 1 is firmly fused together to form a sand-like core 2, the diameter of which is φ4mm, and each strand of fiber filter material 1 is 6mm higher than the outer surface of the sand-like core 2.

[0014] Two specifications of fiber yarn filter materials have been tested, and the average suspended solids removal rate is 99%, the backwash water consumption rate is 1.2%, and the remaining mud accumulation rate is 1%, reaching the domestic leading level under the condition of a filtration rate of 40m / h and a filtration cycle of 20h .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com