Preparation method of fried dough twists without additives

A technology without additives and twist, which is applied in the field of food processing, can solve the problems of high production cost, high cholesterol, and low crispy taste, and achieve the effect of low production and manufacturing costs, reduced oil consumption, and crispy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw material preparation:

[0020] 10 catties of flour, 6 catties of flour fertilizer, 2 catties of high-temperature gluten-breaking flour, 100 grams of salt, 100 grams of sugar, and 4 catties of warm water.

[0021] Preparation of high-temperature gluten-breaking flour: mix flour and hot oil (salad oil) at a weight ratio of 1:0.4, stir evenly, spread to cool, pulverize and pass through a 60-mesh sieve, and the temperature of the hot oil is 200°C.

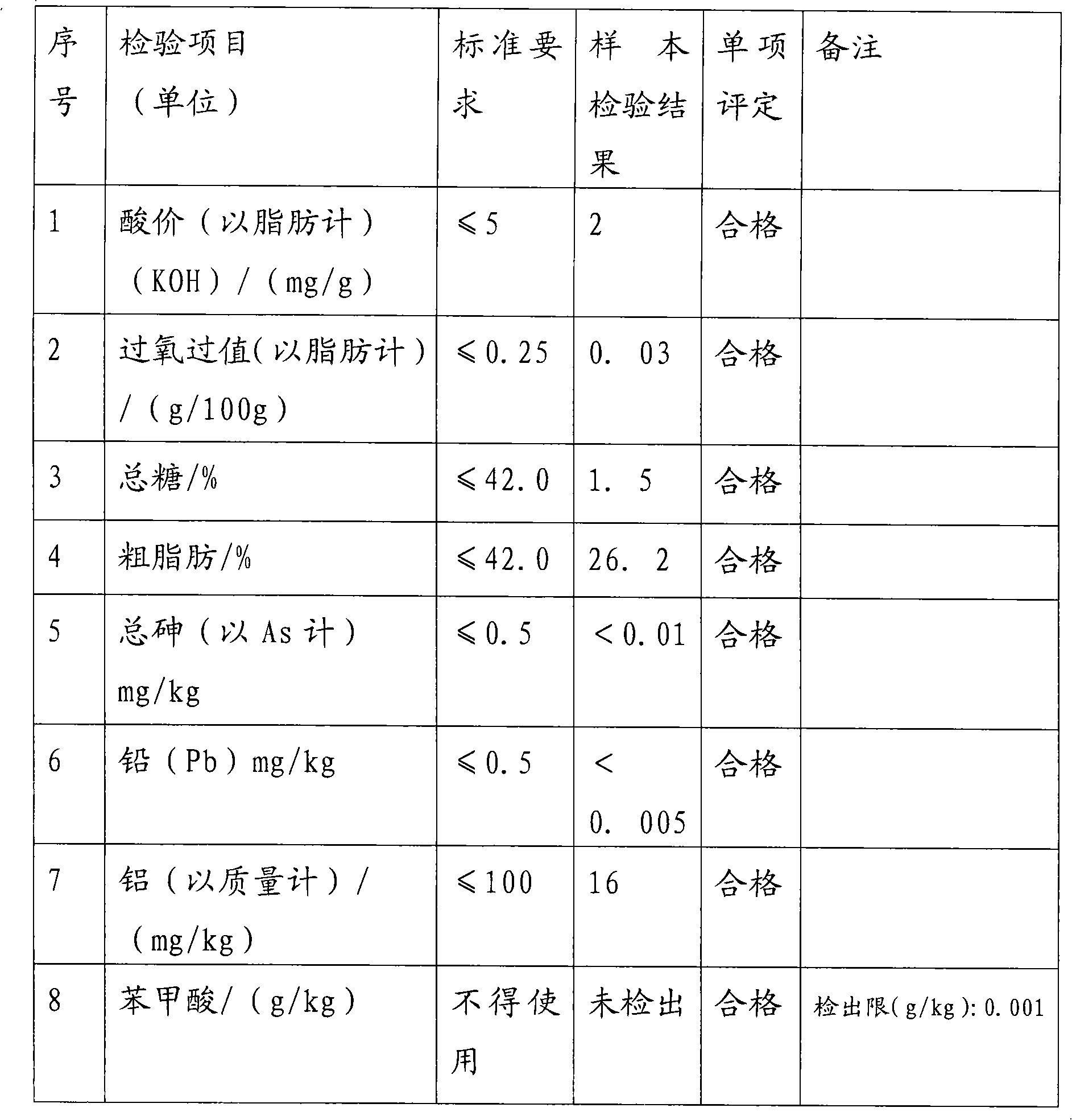

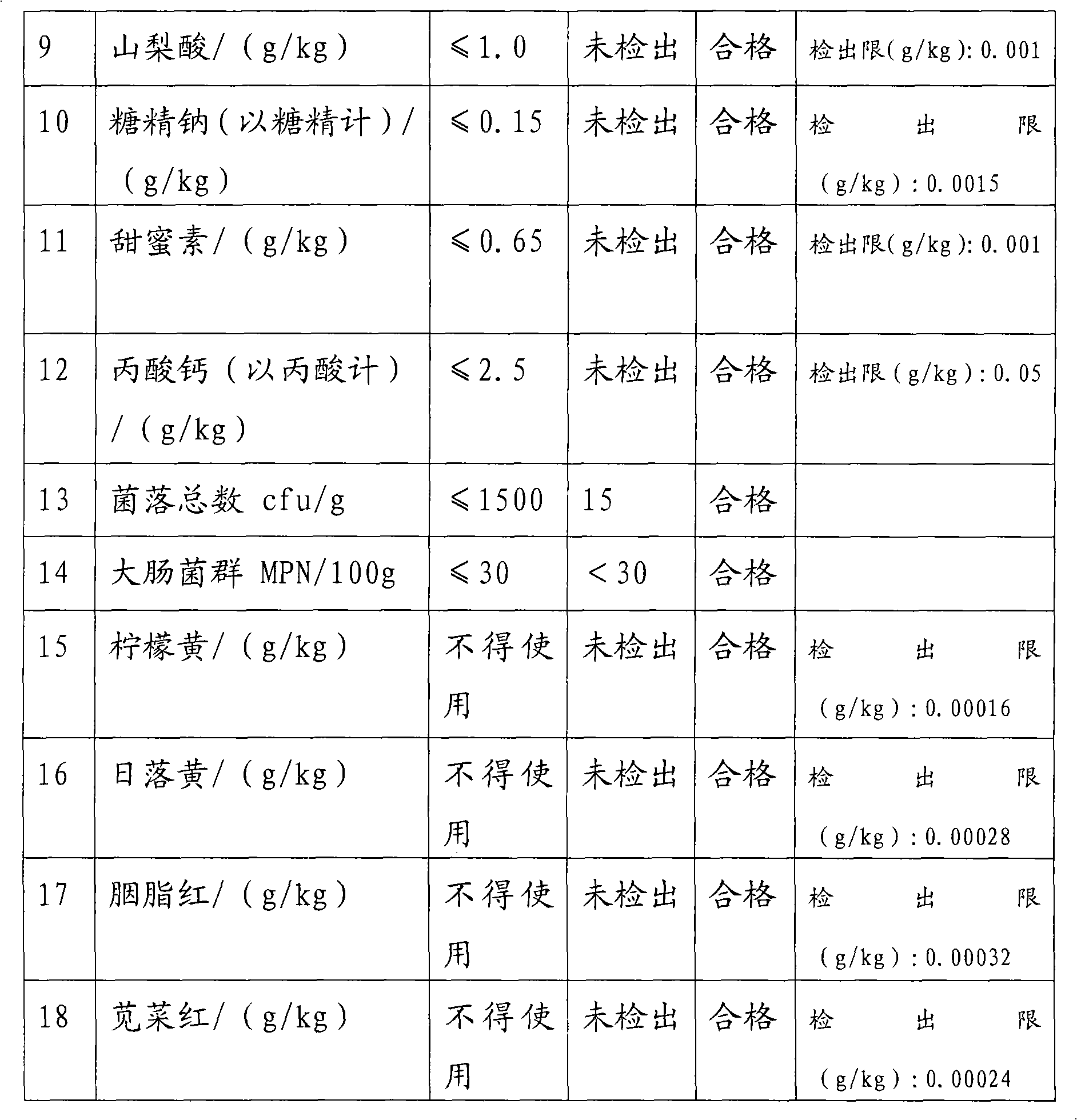

[0022] Preparation of Mahua: Mix salt, sugar and flour fertilizer with warm water, pour in high-temperature gluten-breaking powder and mix well, and finally pour in flour and knead evenly to form a dough, then knead the dough into three strands of twisted doughnuts and deep-fry in an oil pan until the twisted doughnuts float out of oil When the noodles are ripe, remove them. The test report is shown in Table 1.

Embodiment 2

[0024] Raw material preparation:

[0025] 10 catties of flour, 9 catties of flour fertilizer, 4 catties of high-temperature gluten-breaking flour, 120 grams of salt, and 6 catties of warm water.

[0026] The preparation of high-temperature gluten-breaking powder: flour and hot oil (vegetable oil) are mixed with the ratio of weight ratio 1: 0.2, spread cool after stirring evenly, pulverize and cross 50 mesh sieves. The oil temperature of the hot oil is 180°C.

[0027] All the other are with embodiment 1.

Embodiment 3

[0029] Raw material preparation:

[0030] 10 catties of flour, 7.5 catties of flour fertilizer, 3 catties of high-temperature gluten-breaking flour, 500 grams of sugar, and 5 catties of warm water.

[0031] Preparation of high-temperature gluten-breaking flour: mix flour and hot oil at a weight ratio of 1:0.3, stir evenly, spread to cool, pulverize and pass through a 40-mesh sieve, and the temperature of the hot oil is 250°C.

[0032] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com