A treatment, regeneration and cyclic utilization method for tobacco sheet production wastewater

A technology for the production of waste water and tobacco flakes, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of substandard discharge of waste water, long process flow and large equipment investment, etc. problem, to achieve the effect of preventing scaling and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

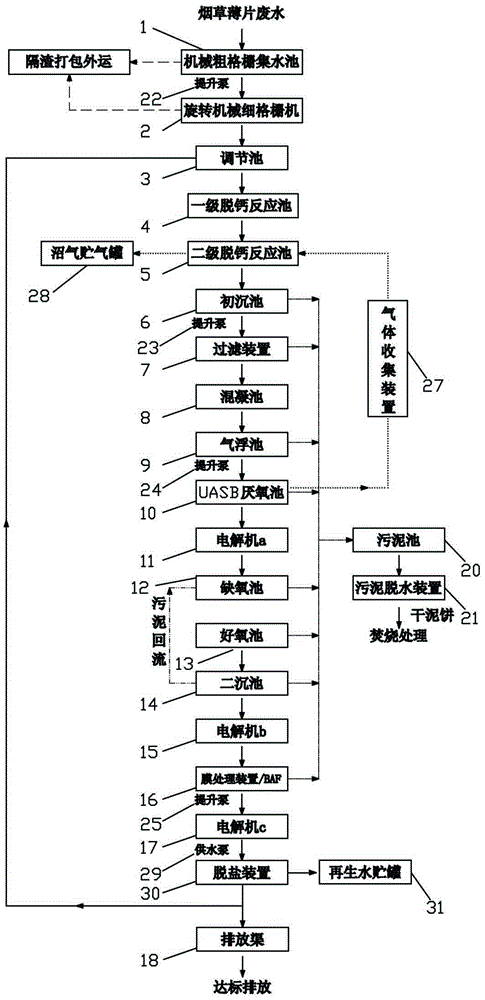

Image

Examples

Embodiment 1

[0055] A method for treating and regenerating and recycling 20 tons / day of tobacco sheet production wastewater.

[0056] The water quality index of the described tobacco sheet production wastewater is determined as shown in Table 2.

[0057]

[0058] (1) Slag removal

[0059] The waste water from tobacco sheet production is collected by the pipeline and then discharged into the mechanical coarse grid collecting tank 1. The coarse grid is set in the pool to isolate and remove the medium and coarse floating objects in the sewage, so as to prevent the blockage of the subsequent treatment equipment. The waste water from tobacco sheet production is lifted into the rotary mechanical fine grid machine 2, and most of the insoluble suspended solids in the water are further removed through the filtration of the filter screen.

[0060] (2) Chemical decalcification

[0061] The effluent after slag removal first flows into the adjustment tank 3 through the pipeline, and then enters th...

Embodiment 2

[0085] A method for treating and regenerating and recycling 50 tons / day of tobacco sheet production wastewater.

[0086] The water quality index of the described tobacco sheet production wastewater is determined as shown in Table 5.

[0087]

[0088] (1) Slag removal

[0089] The waste water from tobacco sheet production is collected by the pipeline and then discharged into the mechanical coarse grid collecting tank 1. The coarse grid is set in the pool to isolate and remove the medium and coarse floating objects in the sewage, so as to prevent the blockage of the subsequent treatment equipment. The waste water from tobacco sheet production is lifted into the rotary mechanical fine grid machine 2, and most of the insoluble suspended solids in the water are further removed through the filtration of the filter screen.

[0090] (2) Chemical decalcification

[0091] The effluent after slag removal first flows into the adjustment tank 3 through the pipeline, and then enters th...

Embodiment 3

[0115] A method for treating and regenerating 10 tons / day waste water from tobacco sheet production.

[0116] The water quality index of the described tobacco sheet production wastewater is determined as shown in Table 8.

[0117]

[0118] (1) Slag removal

[0119] The waste water from tobacco sheet production is collected by the pipeline and then discharged into the mechanical coarse grid collecting tank 1. The coarse grid is set in the pool to isolate and remove the medium and coarse floating objects in the sewage, so as to prevent the blockage of the subsequent treatment equipment. The waste water from tobacco sheet production is lifted into the rotary mechanical fine grid machine 2, and most of the insoluble suspended solids in the water are further removed through the filtration of the filter screen.

[0120] (2) Chemical decalcification

[0121] The effluent after slag removal first flows into the adjustment tank 3 through the pipeline, and then enters the first-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com