Terahertz soft waveguide tube based on PTFE material and forming method thereof

A molding method and waveguide technology, applied in the field of electronics, can solve problems such as inability to shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

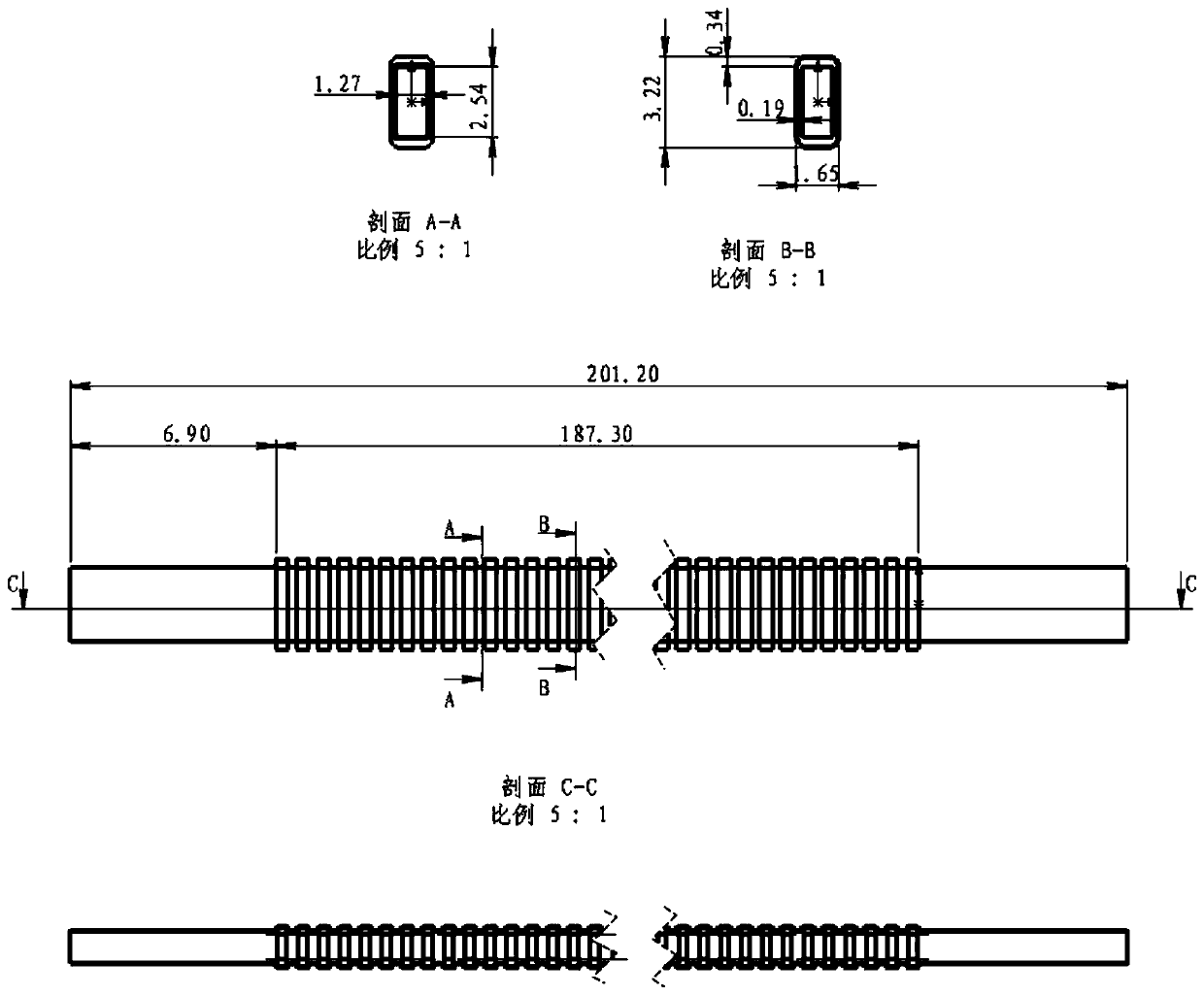

[0038] This embodiment proposes a method for forming a PTFE-based terahertz flexible waveguide, which includes the following steps:

[0039] (1) After simulation and analysis of electromagnetic characteristics, the theoretical structure diagram of the flexible waveguide with a working frequency of 50-500 GHz and a cavity made of PTFE as the medium is obtained;

[0040] (2) According to the structure of the terahertz flexible waveguide, after analysis and investigation, PTFE rods are used as the substrate, and frequency-second laser cutting or CNC processing can be used. The present invention adopts the frequency-second laser processing of Dezhong Technology Development Company Equipment, the wavelength of the laser is 355nm, the power is 28W, the processing axis X / Y / Z axis resolution is 1μm, the repeated positioning accuracy of this equipment is -2μm~+2μm, which can ensure the accuracy of processing and repeated clamping, and then adopt the auxiliary deburring process To reali...

Embodiment 2

[0045] This embodiment proposes a method for forming a PTFE-based terahertz flexible waveguide, which includes the following steps:

[0046] (1) After simulation and analysis of electromagnetic characteristics, the theoretical structure diagram of the flexible waveguide with a working frequency of 50-500 GHz and a cavity made of PTFE as the medium is obtained;

[0047] (2) According to the structure of the terahertz flexible waveguide, after analysis and investigation, PTFE rods are used as the substrate, and frequency-second laser cutting or CNC processing can be used. The present invention adopts the frequency-second laser processing of Dezhong Technology Development Company Equipment, the wavelength of the laser is 355nm, the power is 32W, the processing axis X / Y / Z axis resolution is 1.2μm, the repeated positioning accuracy of this equipment is -2μm~+2μm, which can ensure the accuracy of processing and repeated clamping, and then use auxiliary deburring The process realizes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com