Biomass quality-based utilization system and method based on hydrothermal technology

A biomass and hydrothermal technology, applied in chemical instruments and methods, water pollutants, biological sludge treatment, etc., can solve the problems of insufficient subdivision, insufficient sludge treatment, and inefficient resource utilization of products , to achieve excellent dehydration performance, improve the efficiency of resource utilization of products, and improve the value of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

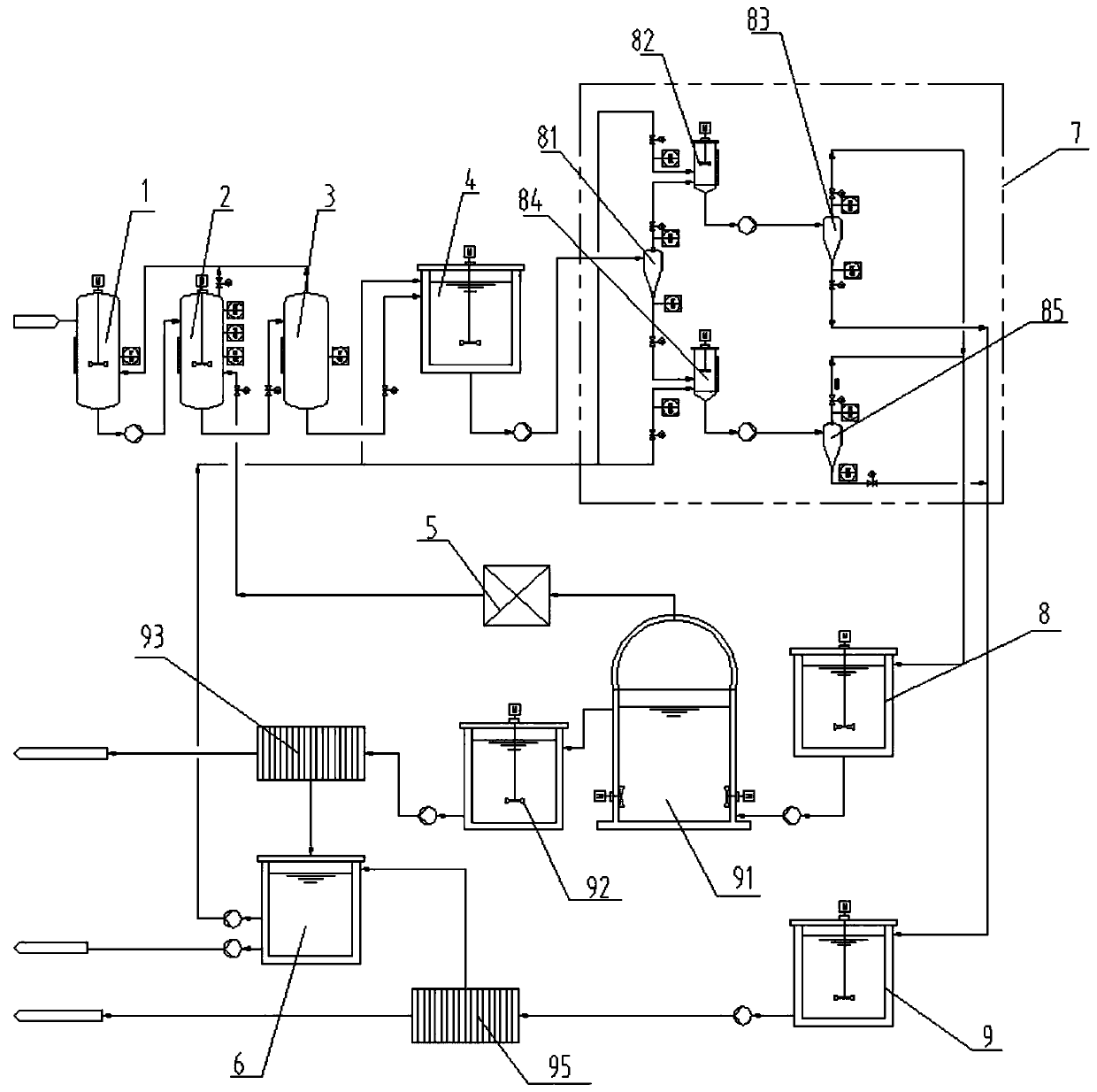

[0037] like figure 1 As shown, a biomass fractionation and utilization system based on hydrothermal technology includes a pretreatment tank, a hydrothermal reactor 2, a flash reactor 3, a hydrothermal sludge buffer tank 4, a biogas boiler 5, and a filtrate buffer tank 6 and a multistage cyclone separation system 7; the pretreatment tank described in this system can be a slurry reactor 1; the slurry reactor 1 is connected with the hydrothermal reactor 2 through a hydrothermal feed pump, and the hydrothermal The reactor 2 is connected to the flash reactor 3 through a pipeline, the steam outlet of the flash reactor 3 is connected to the slurry reactor 1, and the flash reactor 3 is connected to the hydrothermal sludge buffer tank 4 through a pipeline The steam outlet end of the biogas boiler 5 is connected with the hydrothermal reaction; the hydrothermal sludge buffer tank 4 is connected with the multi-stage cyclone separation system 7 through a primary separation pump; the filtra...

Embodiment 2

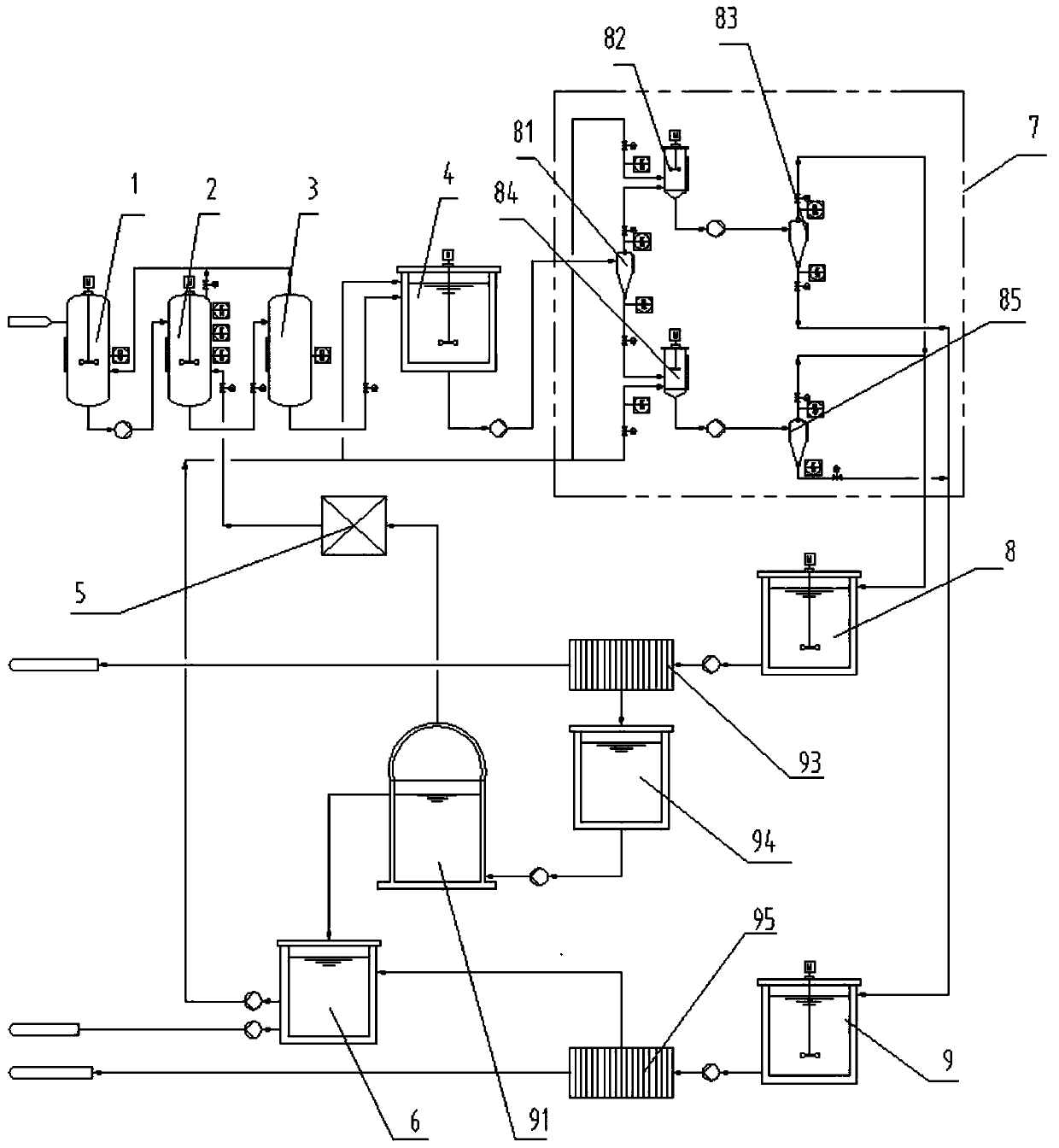

[0054] like figure 2 Described, embodiment 2 is similar to embodiment 1, and its difference is, described organic sludge buffer tank 8 rear end is provided with organic sludge dehydrator 93, organic filtrate buffer tank 947 and anaerobic reactor 91; The sludge buffer tank 8 is connected with the organic sludge dewaterer 93 through the feed pump of the organic sludge dewaterer 93, and the liquid outlet of the organic sludge dewaterer 93 is connected with the organic filtrate buffer tank 947, and the organic filtrate buffer tank 947 collects The dehydrated filtrate, then the organic filtrate buffer pool 947 is connected with the anaerobic reactor 91 by the organic filtrate anaerobic feed pump, and the organic filtrate anaerobic feed pump transports the organic filtrate into the anaerobic reactor 91 for reaction, and the anaerobic reactor 91 reacts. The gas outlet of the oxygen reactor 91 is connected with the biogas boiler 5, and the water outlet of the anaerobic reactor 91 is ...

Embodiment 3

[0063] This program provides a biomass fractionation and utilization method based on hydrothermal technology, which specifically includes the following steps:

[0064] Step 1: The sludge is passed into the slurry reactor 1, preheated to 95-100°C by the flash steam from the flash reactor 3; then pumped into the hydrothermal reactor 2 by the hydrothermal feed pump , is heated to 160-185°C by the steam generated by the biogas boiler 5; then it enters the flash reactor 3 by gravity flow through the pressure difference, and at the same time of lowering the temperature and pressure, the flash steam is obtained and reused in the slurry reactor 1. The flash sludge temperature is 95-105°C;

[0065] Step 2: The flash sludge flows to the hydrothermal sludge buffer tank 4 by gravity. The solid content of the hydrothermal sludge is 12% to 18%, and the dynamic viscosity is 100-500mPa·s; it needs to be buffered in the hydrothermal sludge Dilution is carried out in the pool 4, the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com