Vehicle-mounted hydrogen supply system and method based on hollow fiber membrane microreactor

A technology of micro-reactor and fiber membrane, which is applied in the field of liquid organic hydride catalytic hydrogen production, can solve the problems of low safety, high cost and high energy consumption, and achieve the effects of wide application, low installation cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

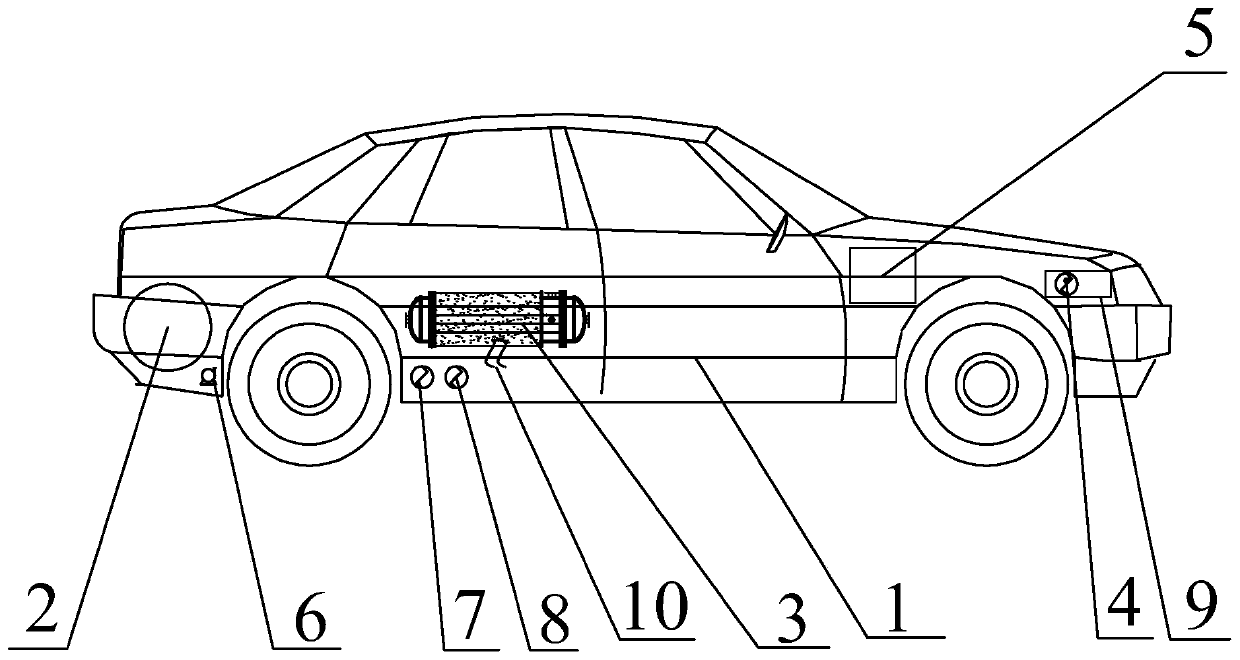

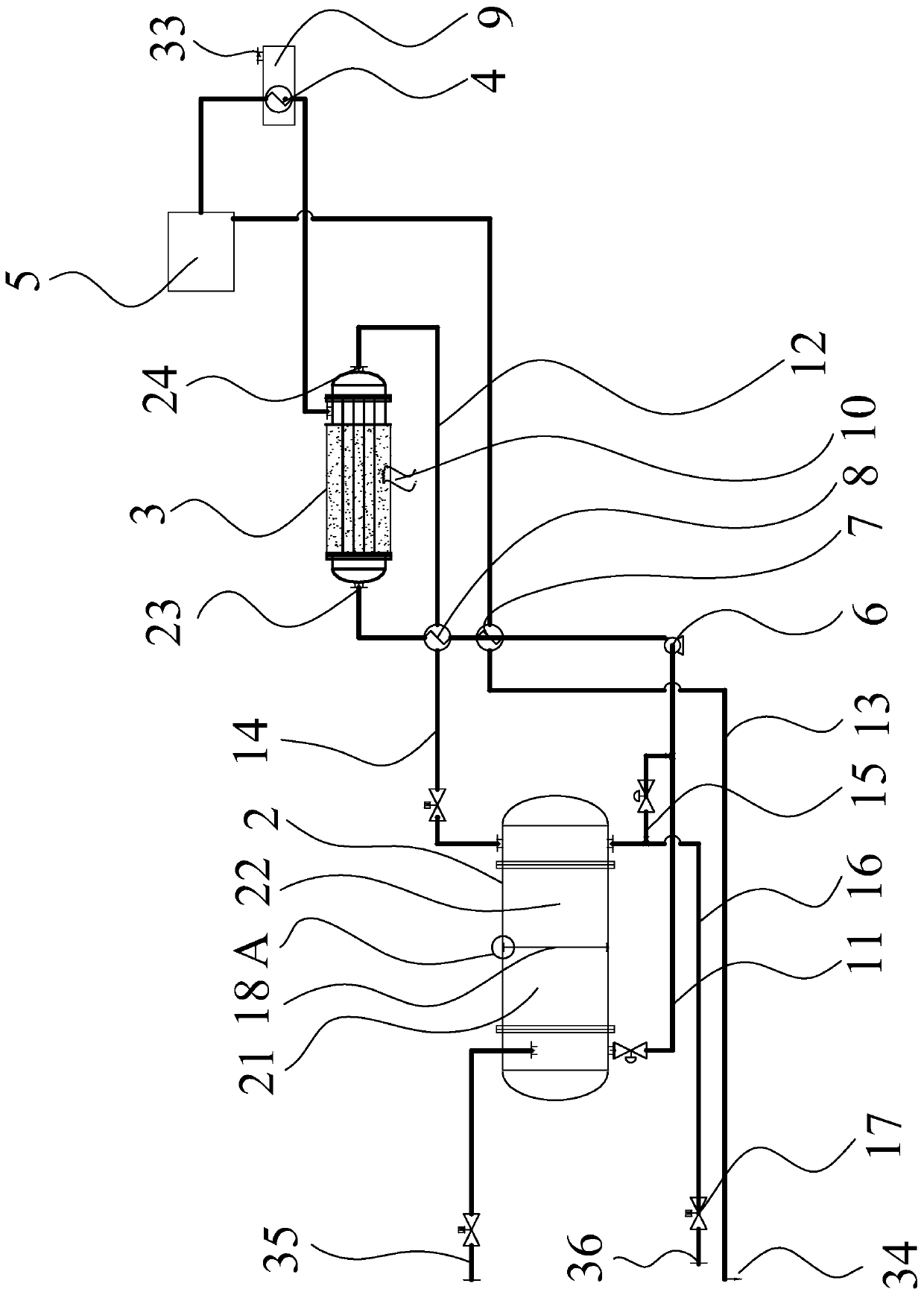

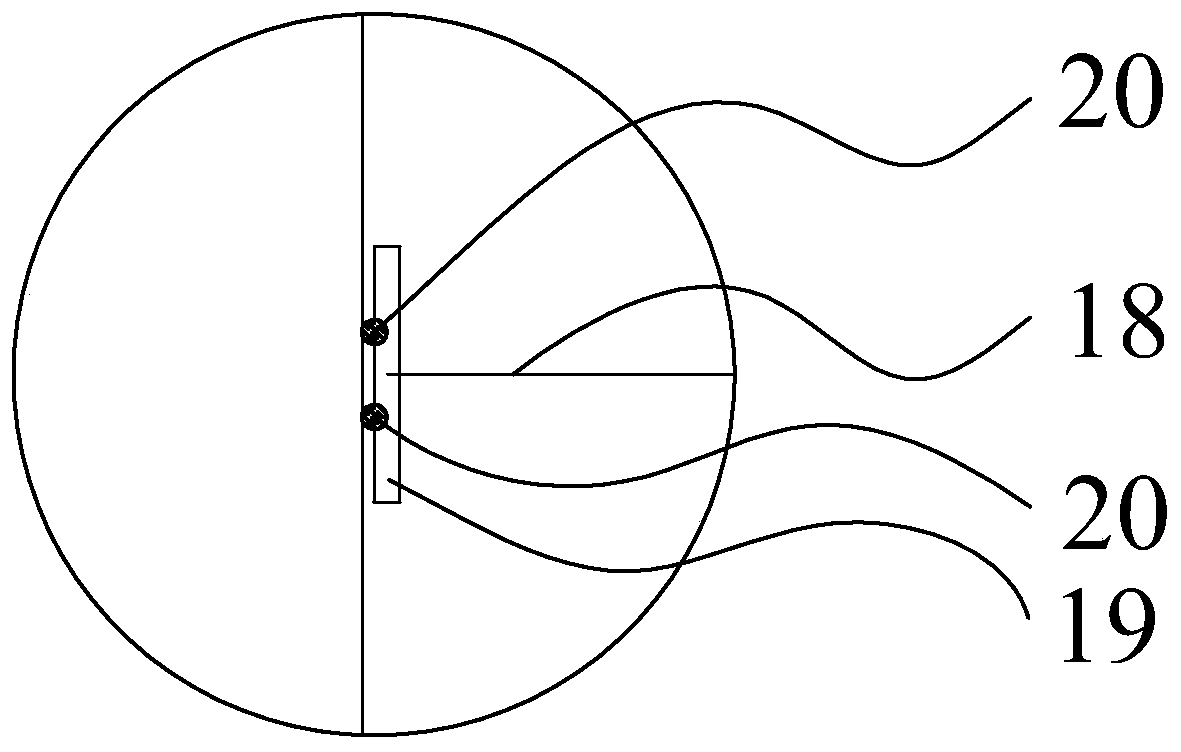

[0055] Such as figure 2 As shown, a vehicle-mounted hydrogen supply system based on a hollow fiber membrane microreactor, including a hydrogen oil-oil storage tank 2, a hollow fiber membrane microreactor 3, a cooler 4, a vehicle-mounted air-cooled water tank 9, a heat exchange system and fuel Battery system 5; the interior of the hydrogen oil-oil storage tank is separated by a separator assembly to form a hydrogen oil chamber 21 and an oil storage chamber 22, see image 3 , the separator assembly includes a piston-type separator 18, a piston ring 19 and two sealing piston rings 20; "The inlet 23 is connected, and the outlet "oil storage" outlet 24 of the hollow fiber membrane microreactor is connected with the inlet of the oil storage cavity through the discharge pipeline 12. The outlet end of the oil storage chamber includes a first pipeline 15 communicating with the feed pipeline and a second pipeline 16 provided with an oil pump 17 . The discharge pipeline includes a thi...

Embodiment 2

[0075] The difference between Example 2 and Example 1 is that the vehicle-mounted hydrogen supply system based on the hollow fiber membrane microreactor has 24 array reaction tubes, the dehydrogenation catalyst is a Pt-Mo bimetallic series, and the length of the alumina hollow fiber tube is 50 cm. The outer surface of the middle section is coated with Pd film, the hydrogen oil is selected from cyclohexylbenzene, and the rest of the system structure is exactly the same.

[0076] A vehicle-mounted hydrogen supply method based on a hollow fiber membrane microreactor, comprising the following steps:

[0077] (1) Vacuumize the hollow fiber membrane micro-reactor 3 first, and then pass nitrogen gas into it. Under the protection of nitrogen gas, heat it to 305°C through the electromagnetic heating module 10 and keep the temperature constant, and stop the nitrogen gas flow;

[0078] (2) Start the feeding system, pump out the oil storage from the oil storage chamber 21, add cyclohexylb...

Embodiment 3

[0083] The difference between Example 3 and Example 1 is that the vehicle-mounted hydrogen supply system based on the hollow fiber membrane microreactor has 32 array reaction tubes, the dehydrogenation catalyst is a Rh-based dehydrogenation catalyst, and the zirconia hollow fiber tube (YSZ) is used. The length of the zirconia hollow fiber tube is 60cm, and the outer surface of the middle section is coated with Pd film. The hydrogen oil is a liquid organic hydride mixed with equal volumes of methyldecalin and carbazole. The rest of the system structure is exactly the same.

[0084] A vehicle-mounted hydrogen supply method based on a hollow fiber membrane microreactor, comprising the following steps:

[0085] (1) Vacuum the hollow fiber membrane micro-reactor 3 first, and then feed nitrogen gas. Under the protection of nitrogen gas, heat it to 330°C through the electromagnetic heating module 10 and keep the temperature constant, and stop feeding nitrogen gas;

[0086] (2) Start ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com