Degradable box sealing adhesive tape

A tape and box sealing technology, applied in the directions of adhesives, packaging sealing/fastening, packaging, etc., can solve the problems of increasing recycling costs, difficulty in recycling packaging boxes, environmental pollution of tapes, etc. The effect of environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

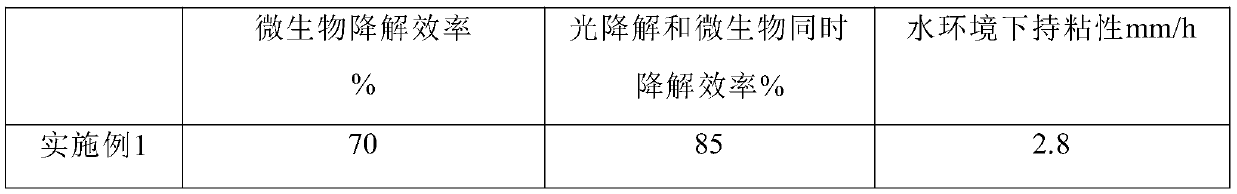

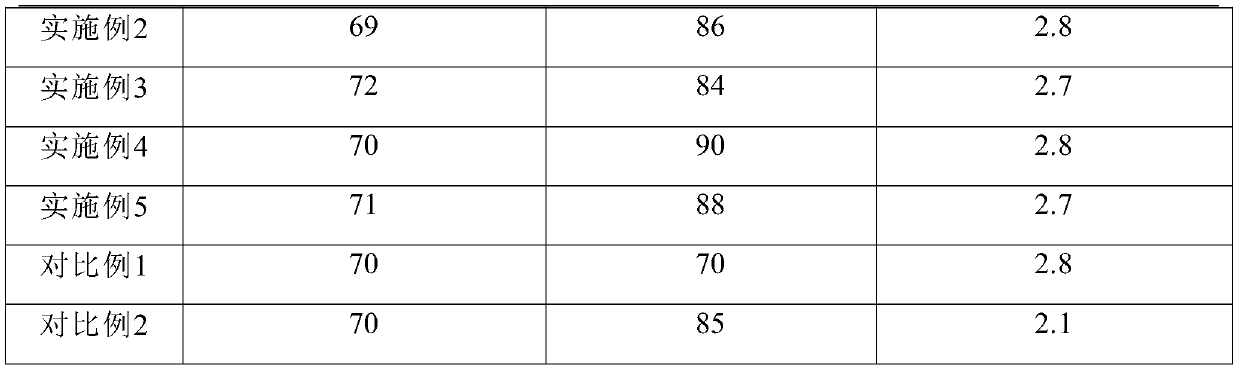

Examples

Embodiment 1

[0032] This embodiment provides a kind of degradable sealing tape, and its preparation method is:

[0033] S1. Extrude the ethylene-vinyl acetate copolymer into a film by hot pressing to obtain the first substrate layer.

[0034] S2. After the protein is heated and modified, it is extruded by hot pressing to form a film to obtain a second substrate layer.

[0035] S3. Prepare the adhesive layer, the adhesive layer is composed of the following parts by weight: 30-60 parts of starch, 2-5 parts of modifier, 5-10 parts of thickener, 5-10 parts of cross-linking agent, pH regulator 2-5 parts, 2-5 parts of adhesive, 1-3 parts of preservative, 2-4 parts of oxidizing agent and 1-2 parts of defoamer.

[0036] Among them, the starch is processed under high temperature and high pressure to improve its solubility. Modifiers are acid anhydrides such as maleic anhydride and succinic anhydride that undergo esterification reactions with starch. The thickener is sodium bentonite, the crossli...

Embodiment 2

[0045]This embodiment provides a kind of degradable sealing tape, which is different from Embodiment 1 in that:

[0046] S1. Extrude the ethylene-ketene copolymer into a film by hot pressing to obtain the first substrate layer.

[0047] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0049] This embodiment provides a kind of degradable sealing tape, which is different from Embodiment 1 in that:

[0050] S2. After modifying the cellulose and starch, extrude the cellulose and starch to form a film by hot pressing to obtain the second substrate layer.

[0051] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com