Power battery thermal management system based on tab liquid cooling mode

A thermal management system, power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low thermal conductivity of diaphragm materials, poor heat transfer effect, good heat transfer performance, etc., and achieve good liquid cooling effect. , Reduce the risk of external short circuit, increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

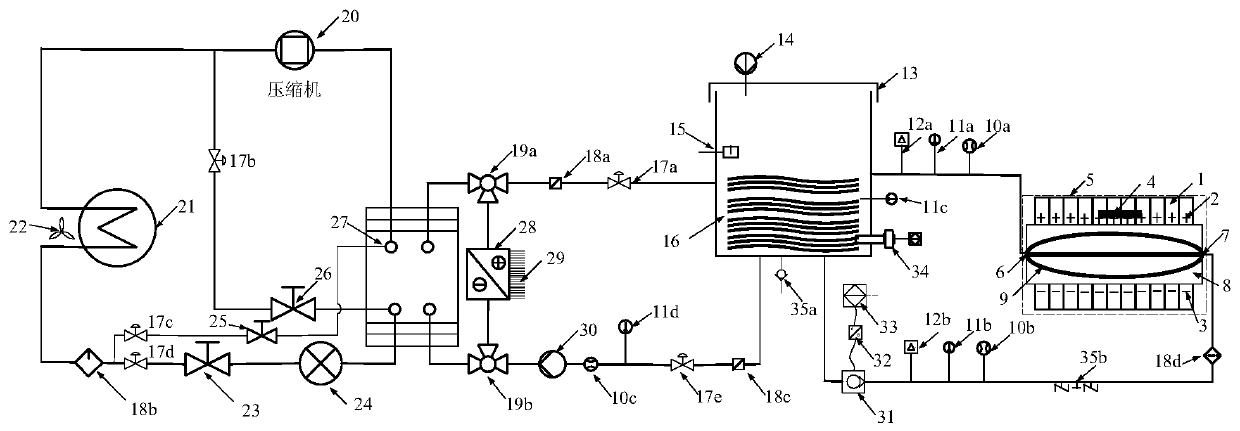

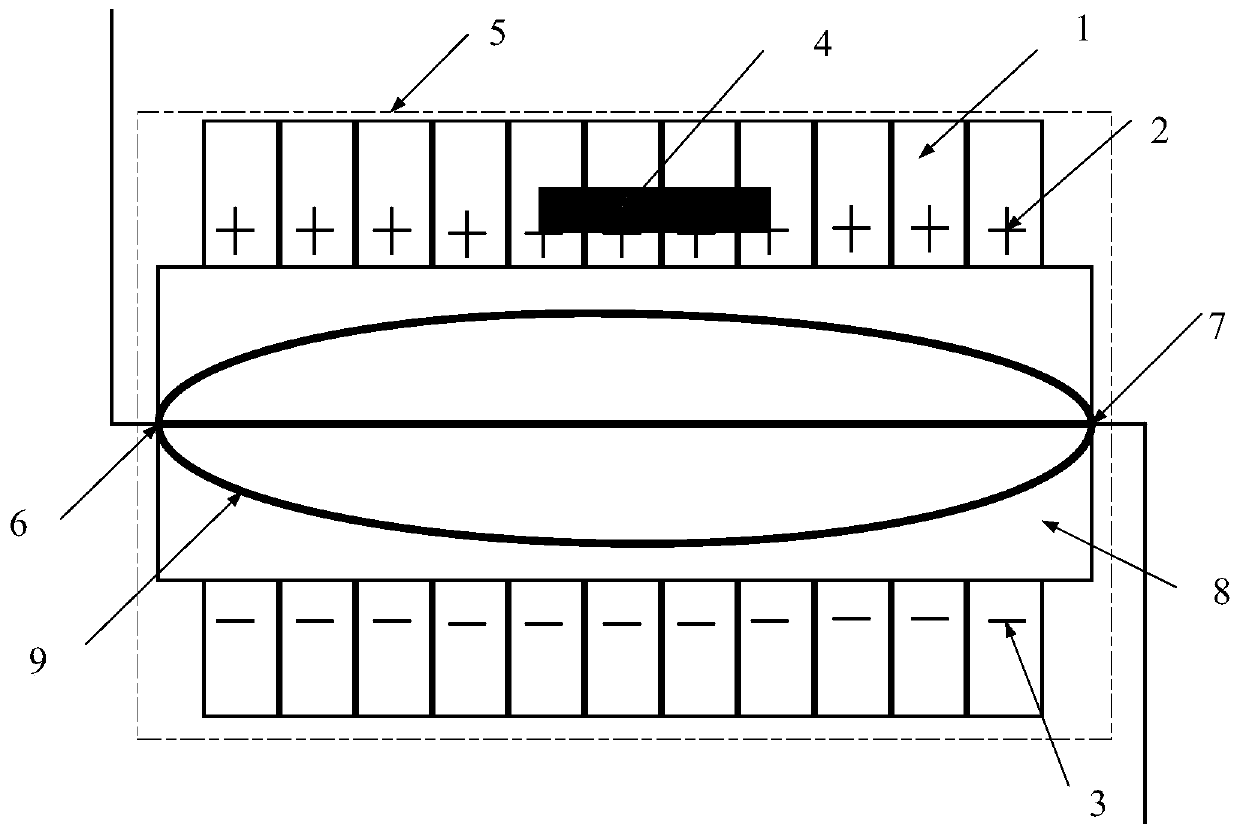

[0021] to combine Figure 1-2 , the present invention provides a power battery thermal management system based on the tab liquid cooling method, by setting the insulation and heat conduction isolation frame and the tab liquid cold plate from bottom to top at the position directly above the tab of the battery module, changing the traditional The side and bottom heat dissipation of the battery is liquid-cooled heat dissipation for the top tab of the battery, which can greatly reduce the heat transfer thermal resistance. The ear liquid cold plate is designed as an arc-shaped flow channel structure, which can reduce the pressure drop of the system and reduce the pump work of the system. Through the unequal spacing design of the lug liquid cold plate flow channel, the temperature gradient at different positions of the battery can be balanced, the temperature uniformit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com