Aqueous gel-state electrolytes, electrode additives and solid-state sodium-ion batteries with low-temperature operating characteristics

A sodium-ion battery, a technology of working characteristics, applied in the direction of electrolyte immobilization/gelation, battery electrodes, secondary batteries, etc., to achieve easy large-scale industrial production, reduce the risk of safety accidents, and simple and easy preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention also shows a preparation method of the solid state sodium ion battery. In some embodiments, the gel electrolyte (electrolyte colloid) is coated on the separator, and the battery including the positive electrode, the negative electrode, the separator and the current collector is assembled and placed in the case. In some other embodiments, the electrolyte is coated on the positive electrode or the negative electrode, and the electrode piece coated with the electrolyte and the current collector are assembled into a battery and placed in the case.

[0033] In addition, the silica-loaded sulfate can also be used as a pole piece additive, and the pole piece additive can be mixed into other battery pole piece raw materials to prepare a battery pole piece. The mass ratio of the pole piece additive may be 5%-40%.

[0034] In some embodiments, the solid-state sodium-ion battery includes both the aqueous gel-state electrolyte and the pole piece additive of the prese...

Embodiment 1

[0039] Preparation of pole piece additive: 15g of particle size 7-40nm, specific surface area 200m 2 50mL of hydrophilic fumed silica / g was dispersed in an aqueous electrolyte solution containing 1mol / L lithium sulfate and 1mol / L sodium sulfate, stirred uniformly for 1 hour, added 50mL methanol, and stirred uniformly for 30 minutes to obtain a low-temperature resistant electrolyte . Put the electrolyte above into an oven (100° C.) and dry it for 2 hours to obtain a silica-supported electrolyte (that is, a pole piece additive).

[0040] Lithium manganate is used as the positive electrode, and polyanthraquinone (PVAQ) is used as the negative electrode. When preparing the battery pole piece, the pole piece additive is mixed into it with a mass ratio of 25wt%. chemical properties.

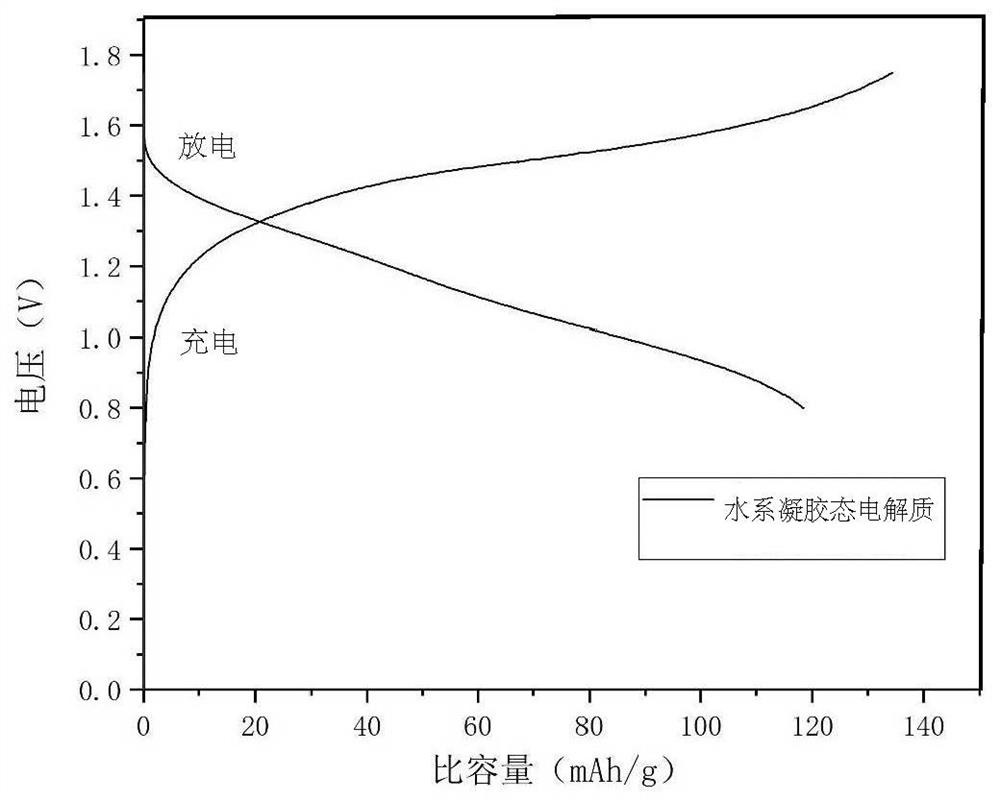

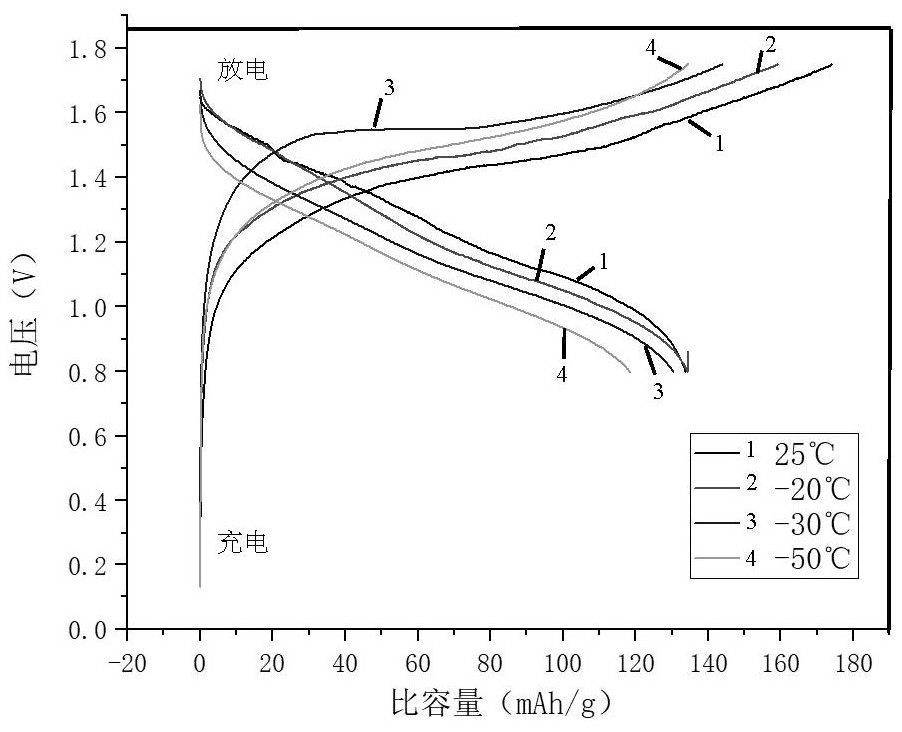

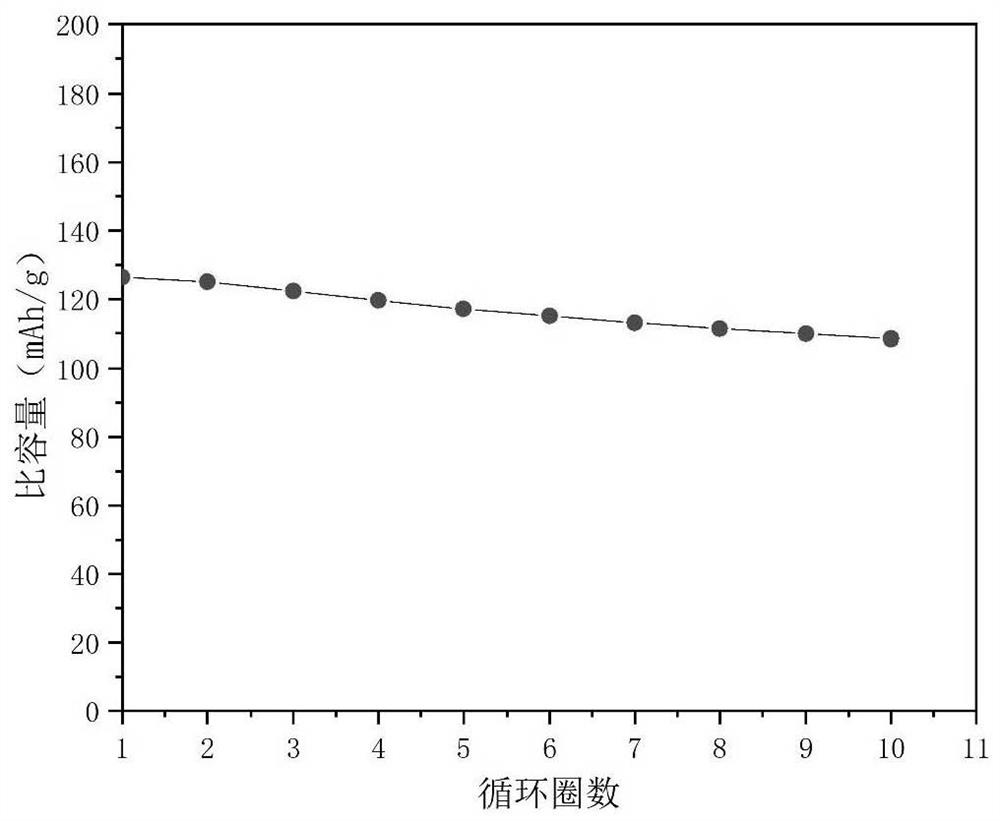

[0041] figure 1 It shows that in the temperature range of -50°C to 25°C, the battery works normally, and the capacity at -50°C is not much different from that at room temperature of 25°C. image 3 ...

Embodiment 2

[0046] Preparation of pole piece additive: Disperse 50 mL of hydrophilic fumed silica with a particle size of 7-40 nm and a specific surface area of 200 m2 / g in an electrolyte solution containing 1 mol / L of lithium sulfate and 1 mol / L of sodium sulfate, and stir evenly for 1 hour , add 50mL of methanol, and stir evenly for 30 minutes to prepare a low temperature resistant electrolyte. Put the above-mentioned electrolyte substance into an oven (100°C) and dry it for 1 hour to obtain a silica-supported electrolyte (that is, an electrode additive). The pole piece additives are added to the positive and negative pole pieces, assembled with the low temperature resistant electrolyte to form a battery, and the battery capacity is tested.

[0047] Compared with the battery (comparative example 1) without adding silica-loaded electrolyte, from Figure 5 It can be seen that the specific capacity of the battery with the addition of the pole piece additive is much higher than that of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com