A modified n, p co-doped lithium titanate negative electrode material and preparation method thereof

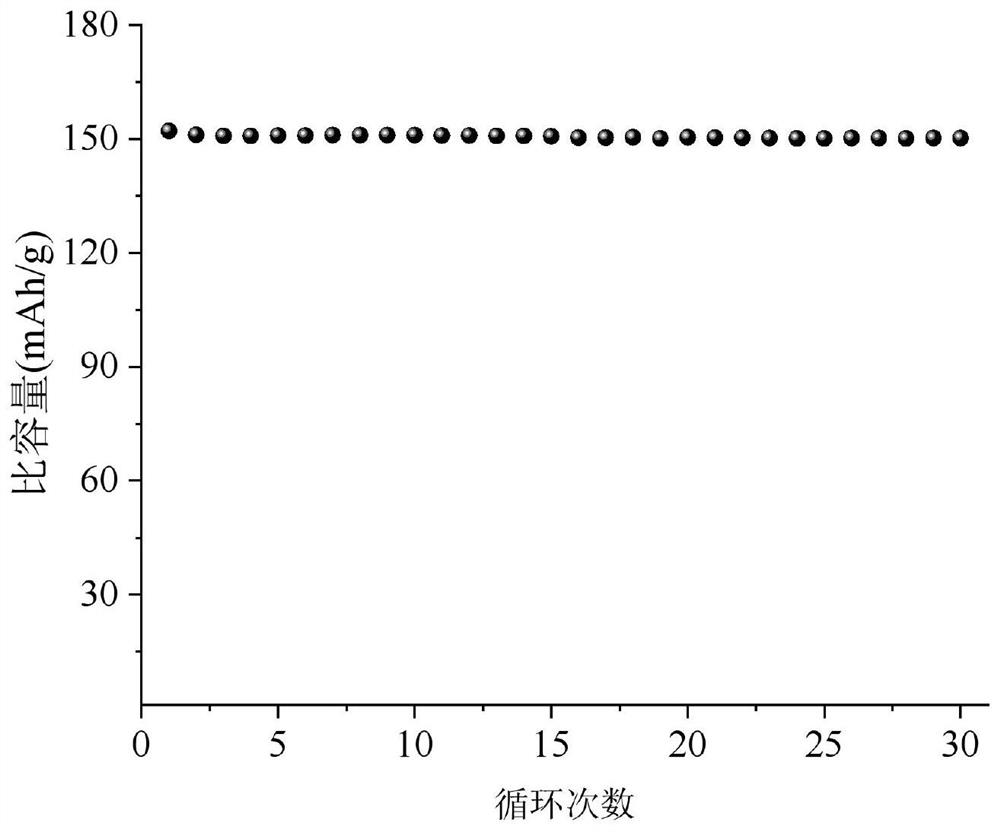

A negative electrode material and co-doping technology, applied in the field of modified N, can solve the problems of low conductivity, low theoretical capacity, low lithium ion diffusion rate, etc., and achieve the effect of high conductivity, uniform particle size and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 0.00405mol LiOH·H 2 O and 0.005mol anatase TiO 2 respectively dissolved in the ball milling condition and mixed uniformly to obtain the precursor. Then the precursor was mixed with anhydrous sodium hypophosphite (NaH 2 PO 2 ) according to the mass ratio of 1:10 placed at both ends of the porcelain boat, wrapped with aluminum foil and placed in a tube furnace, NaH 2 PO 2 Located upstream, in NH 3 and N 2 The mixed gas (volume ratio of the two is 5:95) was heated to 800°C and kept for 12 hours to obtain nitrogen and phosphorus co-doped lithium titanate material.

[0028] A mixture of 1.0g of petroleum pitch, 25g of NaCl and nano-ZnO in a mass ratio of 5:1, a mixture of 25mL of toluene and absolute ethanol in a volume ratio of 6:1 and 0.1g of nitrogen and phosphorus were co-doped with titanic acid Lithium particles were added into a 100mL round bottom flask, ultrasonically dispersed for 0.8h, then magnetically stirred for 22h, and toluene and absolute ethanol were r...

Embodiment 2

[0030] 0.00405mol LiOH·H 2 O and 0.005mol anatase TiO 2 respectively dissolved in the ball milling condition and mixed uniformly to obtain the precursor. Then the precursor was mixed with anhydrous sodium hypophosphite (NaH 2 PO 2 ) according to the mass ratio of 1:10 placed at both ends of the porcelain boat, wrapped with aluminum foil and placed in a tube furnace, NaH 2 PO 2 Located upstream, in NH 3 and N 2 The mixed gas (volume ratio of the two is 5:95) was heated to 800°C and kept for 12 hours to obtain nitrogen and phosphorus co-doped lithium titanate material.

[0031] A mixture of 1.0g of petroleum pitch, 25g of NaCl and nano-ZnO in a mass ratio of 5:1, a mixture of 25mL of toluene and absolute ethanol in a volume ratio of 6:1 and 0.1g of nitrogen and phosphorus were co-doped with titanic acid Lithium particles were added into a 100mL round-bottomed flask, ultrasonically dispersed for 0.5h, then magnetically stirred for 20h, and toluene and absolute ethanol were...

Embodiment 3

[0033] 0.00405mol LiOH·H 2 O and 0.005mol anatase TiO 2 respectively dissolved in the ball milling condition and mixed uniformly to obtain the precursor. Then the precursor was mixed with anhydrous sodium hypophosphite (NaH 2 PO 2 ) according to the mass ratio of 1:10 placed at both ends of the porcelain boat, wrapped with aluminum foil and placed in a tube furnace, NaH 2 PO 2 Located upstream, in NH 3 and N 2 The mixed gas (volume ratio of the two is 5:95) was heated to 800°C and kept for 12 hours to obtain nitrogen and phosphorus co-doped lithium titanate material.

[0034] A mixture of 1.0g of petroleum pitch, 25g of NaCl and nano-ZnO in a mass ratio of 5:1, a mixture of 25mL of toluene and absolute ethanol in a volume ratio of 6:1 and 0.1g of nitrogen and phosphorus were co-doped with titanic acid Lithium particles were added into a 100mL round-bottom flask, ultrasonically dispersed for 1h, then magnetically stirred for 24h, and toluene and absolute ethanol were rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com