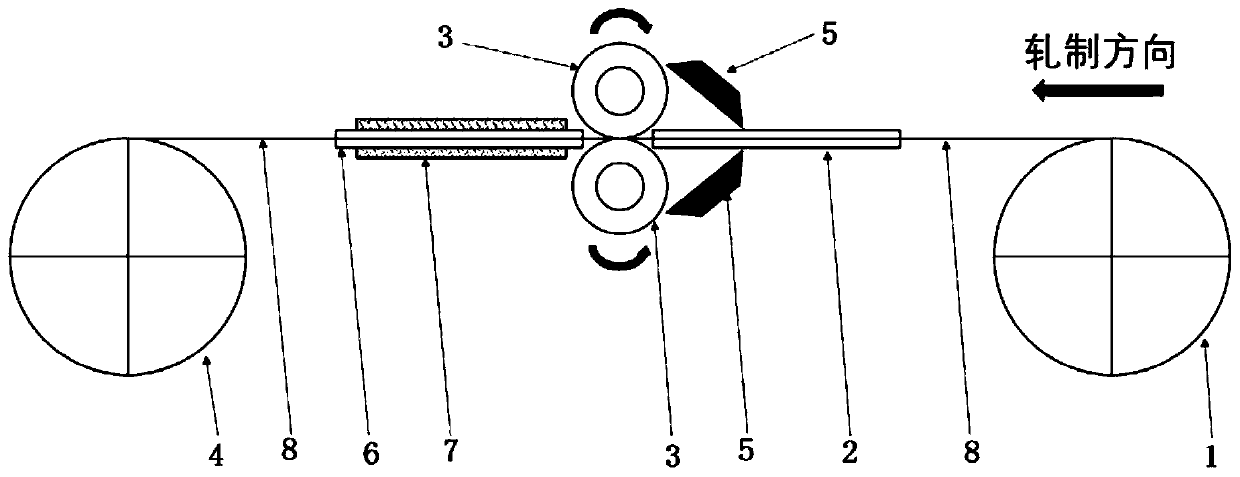

Preparation method and rolling device of iron-based superconducting long wire

An iron-based superconductor and iron-based superconductor technology, which is applied in metal rolling, metal rolling, superconducting devices, etc., can solve problems such as uneven critical current density, achieve consistent hot rolling effects, avoid heat conduction, The effect of improving transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

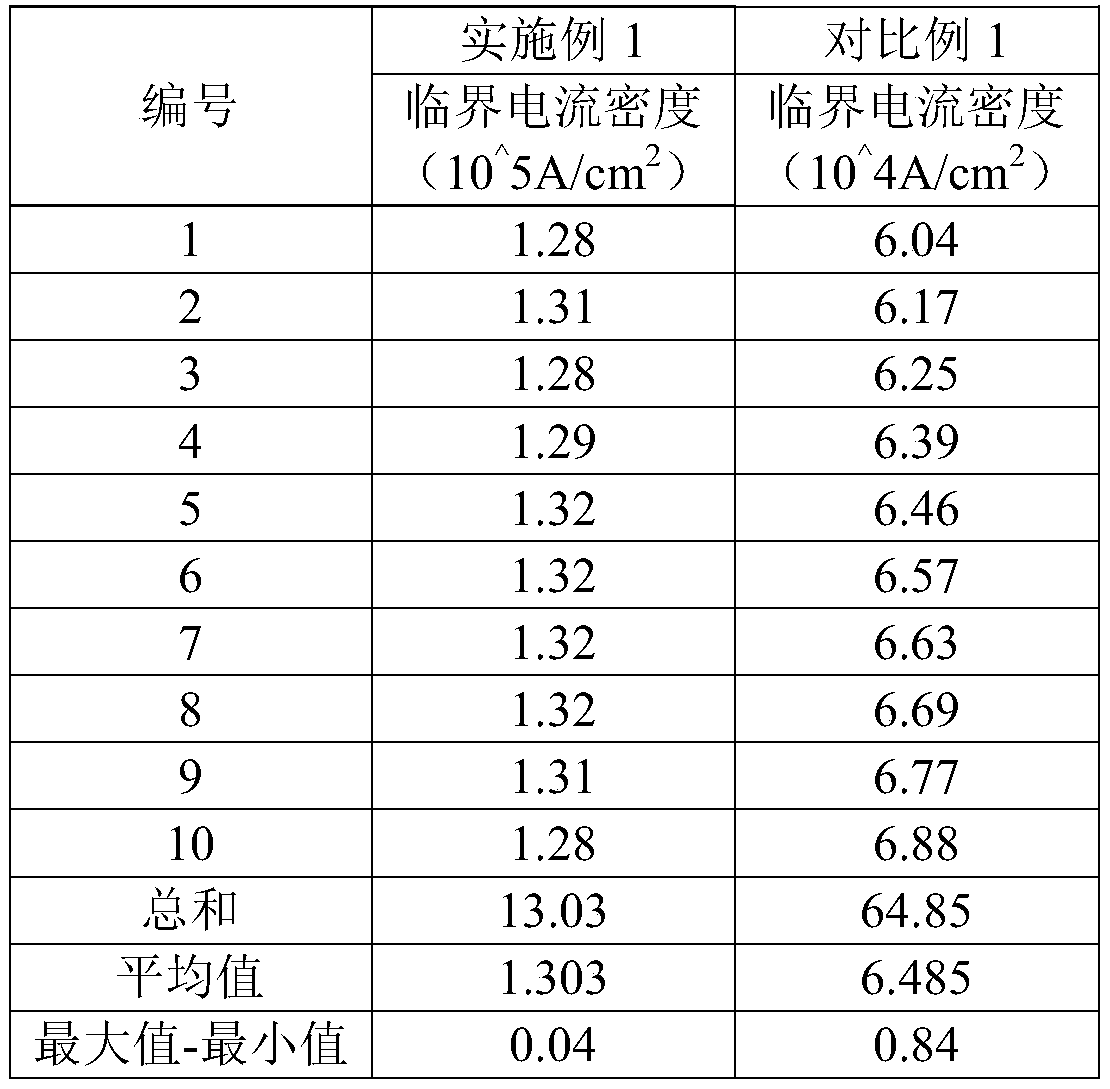

Embodiment 1

[0058] A single core Ba 0.6 K 0.5 Fe 2 As 2 The preparation method of superconducting long wire, the steps are as follows:

[0059] (1) Under the atmosphere of argon gas, the metal barium chips, potassium blocks, iron powder and arsenic particles are accurately weighed according to the molar ratio Ba:K:Fe:As=0.6:0.5:2:2, and then put into the ball mill Ball milling in a tank to mix the powder evenly, heat-treating the ball-milled powder at 950°C and keeping it warm for 40 hours to obtain the iron-based superconductor precursor powder;

[0060] (2) Under an argon atmosphere, fill the iron-based superconductor precursor powder prepared in step (1) into a 0.45m long silver tube, the inner diameter of the silver tube is 5mm, the outer diameter is 8mm, and a copper plug is used Seal the two ends to obtain a tube-packing complex. In air, swage and draw the tube-packing complex to obtain a single-core iron-based superconductor precursor wire with a diameter of 1.9 mm;

[0061] (...

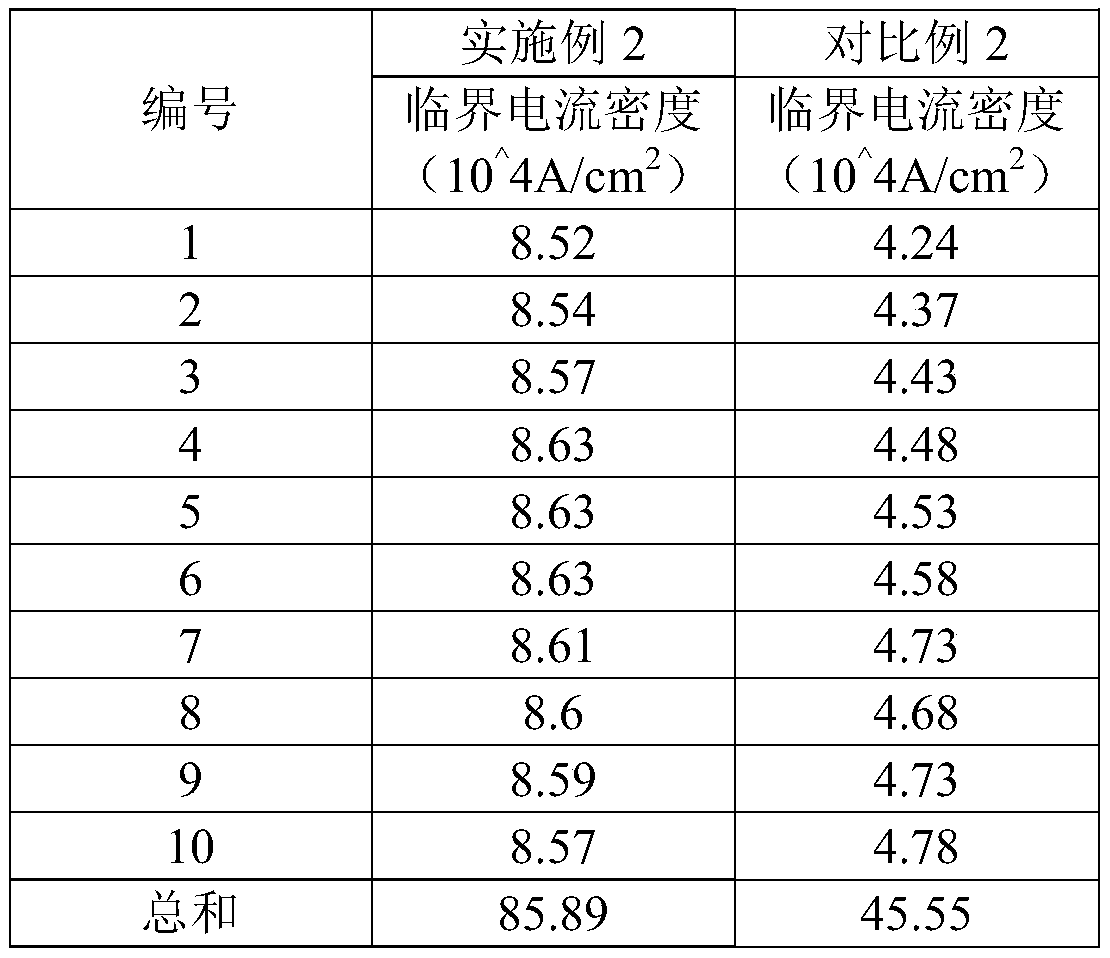

Embodiment 2

[0071] A 7 core Ba 0.6 K 0.4 Fe 2As 2 The preparation method of superconducting long wire, the steps are as follows:

[0072] (1) Under argon atmosphere, accurately weigh barium chips, potassium block, iron powder and arsenic particles according to the molar ratio Ba:K:Fe:As=0.6:0.4:2:2, and put them into the ball mill Ball milling in a tank to mix the powder evenly, heat-treating the ball-milled powder at a temperature of 900°C and keeping it warm for 60 hours to obtain the iron-based superconductor precursor powder;

[0073] (2) Under an argon atmosphere, fill the iron-based superconductor precursor powder prepared in step (1) into a 0.5m long silver tube, the inner diameter of the silver tube is 14mm, the outer diameter is 16mm, and a copper plug is used Seal both ends to obtain a tube-packing complex. In the air, swage and draw the tube-packing complex to obtain a single-core iron-based superconductor precursor wire with a length of 6.3 m and a diameter of 4.46 mm, whi...

Embodiment 3

[0085] A single core Ca 1.14 K 1.05 Fe 4 As 4 The preparation method of superconducting long wire, the steps are as follows:

[0086] (1) Under the atmosphere of argon gas, accurately weigh the metal calcium particles, potassium block, iron powder and arsenic particles according to the molar ratio Ca:K:Fe:As=1.14:1.05:4:4, and put them into the ball mill Ball milling in a tank to mix the powder evenly, heat-treating the ball-milled powder at a temperature of 910°C and keeping it warm for 40 hours to obtain the iron-based superconductor precursor powder;

[0087] (2) Under an argon atmosphere, fill the iron-based superconductor precursor powder prepared in step (1) into a 0.45m long silver tube, the inner diameter of the silver tube is 5mm, the outer diameter is 8mm, and a copper plug is used Seal the two ends, and then put it into a copper tube with an outer diameter of 10mm to obtain a tube-packed complex. In air, swage and pull the tube-packed complex to obtain a single-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com