Dealcoholized condensed double-component room-temperature vulcanized silicone rubber and preparation method thereof

A technology of room temperature vulcanization and dealcohol condensation, which is applied in the field of potting adhesives and can solve problems such as insufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

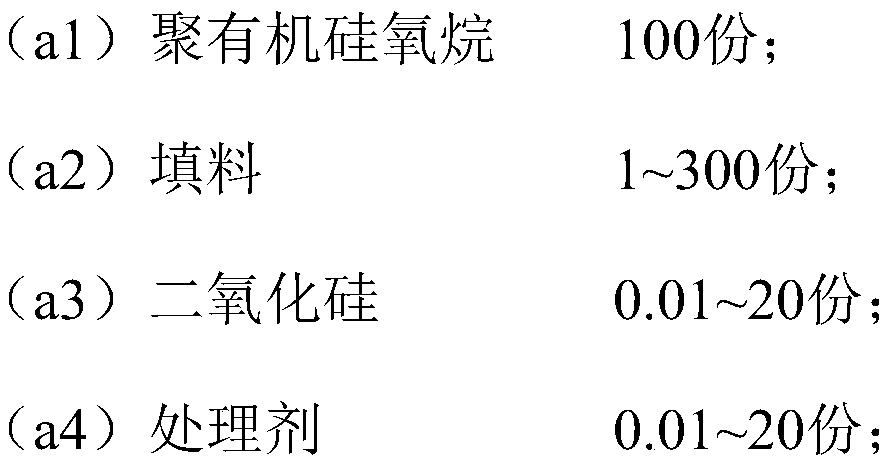

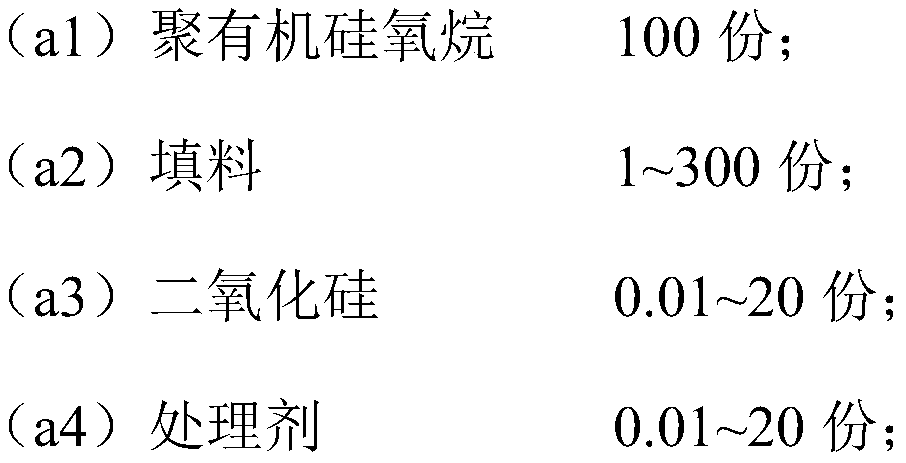

Method used

Image

Examples

Synthetic example 1

[0069] Put 1 mol of N-(2-aminoethyl)-3-aminopropyltrimethoxysilane and 1 mol of 3-glycidyloxypropyltrimethoxysilane into the reaction kettle, and react under constant temperature reflux at 80°C for 2h. Then 2 mol of hexamethyldisilazane was added, the temperature was raised to 140° C. for reflux reaction for 12 hours, and small molecular products and unreacted hexamethyldisilazane were removed under reduced pressure to obtain novel silane compound 1#.

Synthetic example 2

[0071] Put 1 mol of 3-aminopropyltriethoxysilane and 1 mol of 3-glycidyloxypropyltrimethoxysilane into the reaction kettle, reflux at 70°C for 3 hours, and then add 1 mol of hexamethyldisilazol Azane was heated to 130°C for reflux reaction for 18 hours, and the small molecular product and unreacted hexamethyldisilazane were removed under reduced pressure to obtain the new silane compound 2#.

Synthetic example 3

[0073] Put 1 mol of 3-aminopropyltriethoxysilane and 0.5 mol of hexamethyldisilazane into the reaction kettle, reflux at 120°C for 24 hours, and then add 1 mol of 3-(methacryloyloxy ) Propyltrimethoxysilane, reflux reaction at constant temperature at 80°C for 2h, depressurize to remove small molecule products and unreacted hexamethyldisilazane, and obtain novel silane compound 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com