Method for preparing superfine natrium bentonite grout

A technology of sodium-based bentonite and bentonite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unsatisfactory actual effect, large agglomerated particles of bentonite, insufficient sodiumization and organicization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

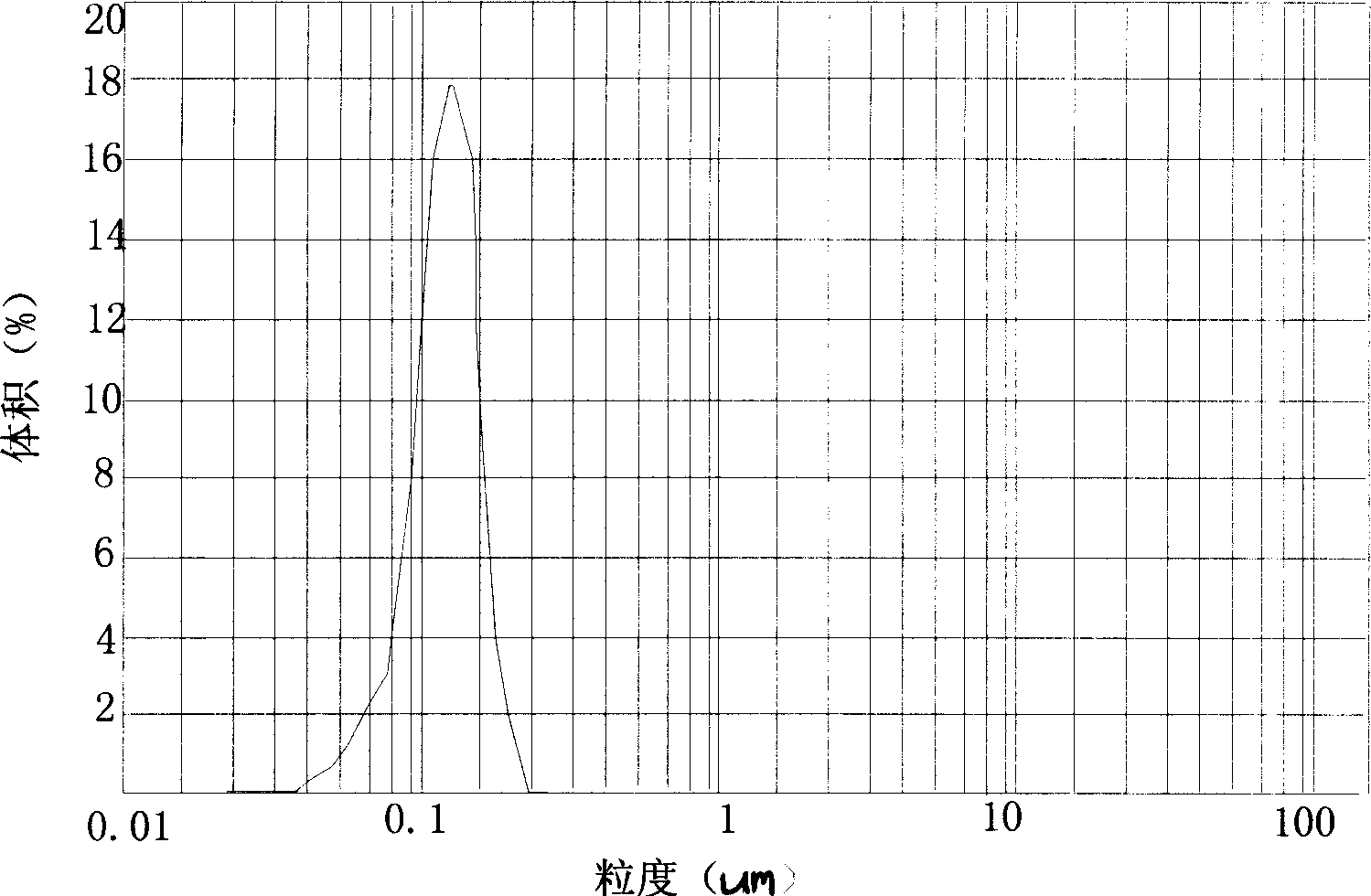

[0022] In a laboratory ball mill, add 20g of sodium bentonite with a montmorillonite content of 92%, add 300ml of water, and stir for 20 minutes to fully wet and disperse the sodium bentonite to form a suspension. Add 240ml of 0.5mm diameter oxidation Zirconium spherical beads were ball-milled for 0.5 hour at a speed of 400 rpm, and the upper layer of slurry was taken to obtain ultrafine sodium-based bentonite slurry.

Embodiment 2

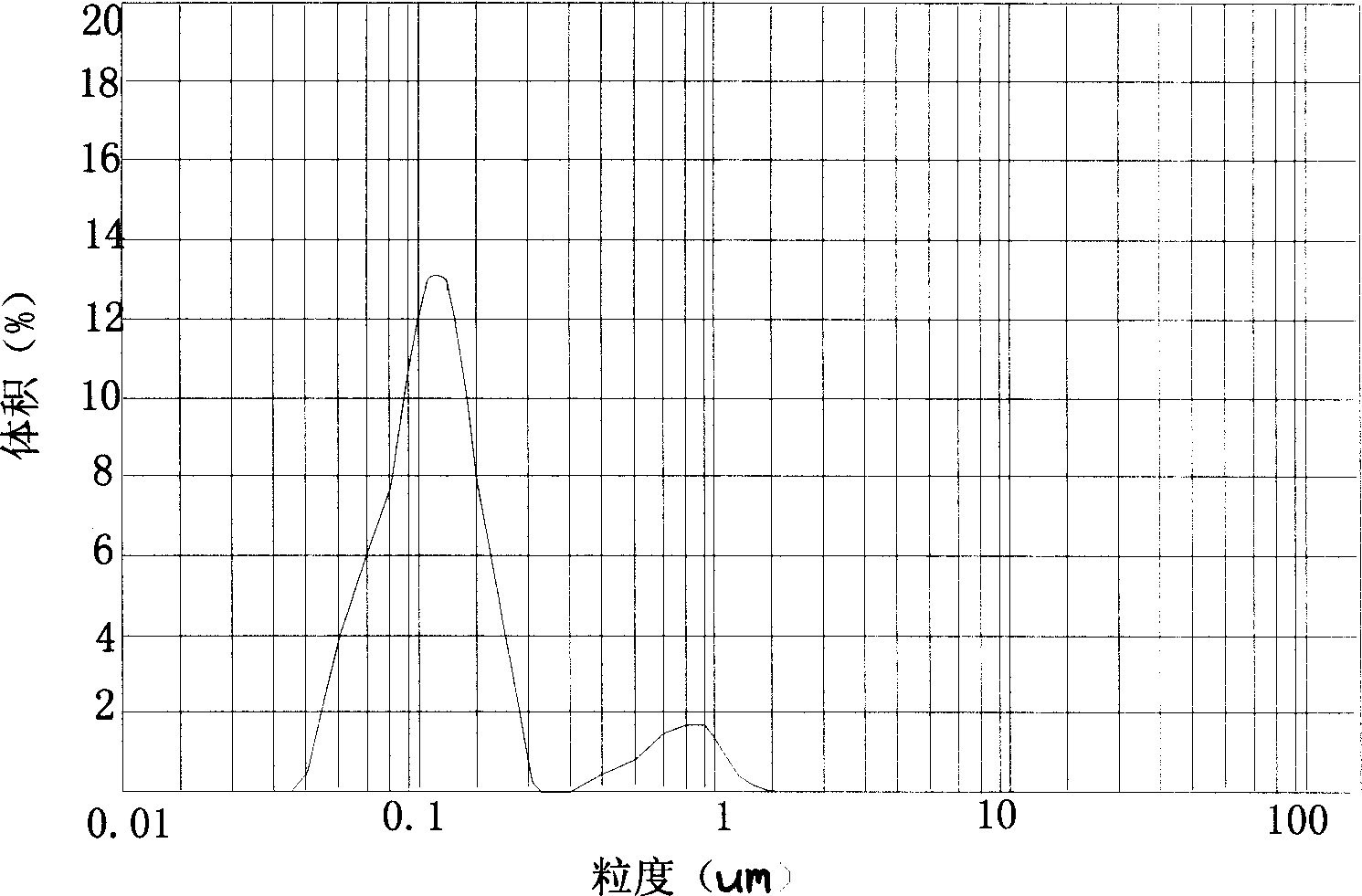

[0024] In a laboratory ball mill, add 20 g of calcium-based bentonite with a montmorillonite content of 92%, add 500 ml of water, and stir for 20 minutes to fully wet and disperse the calcium-based bentonite to form a suspension, add 0.8 g of solid sodium carbonate, and stir for 60 Minutes to completely dissolve the sodium carbonate, add 10mm diameter glass spherical beads with a volume of 300ml, ball mill for 10 hours at a speed of 300 rpm, and take the upper layer slurry to obtain ultrafine sodium bentonite slurry.

Embodiment 3

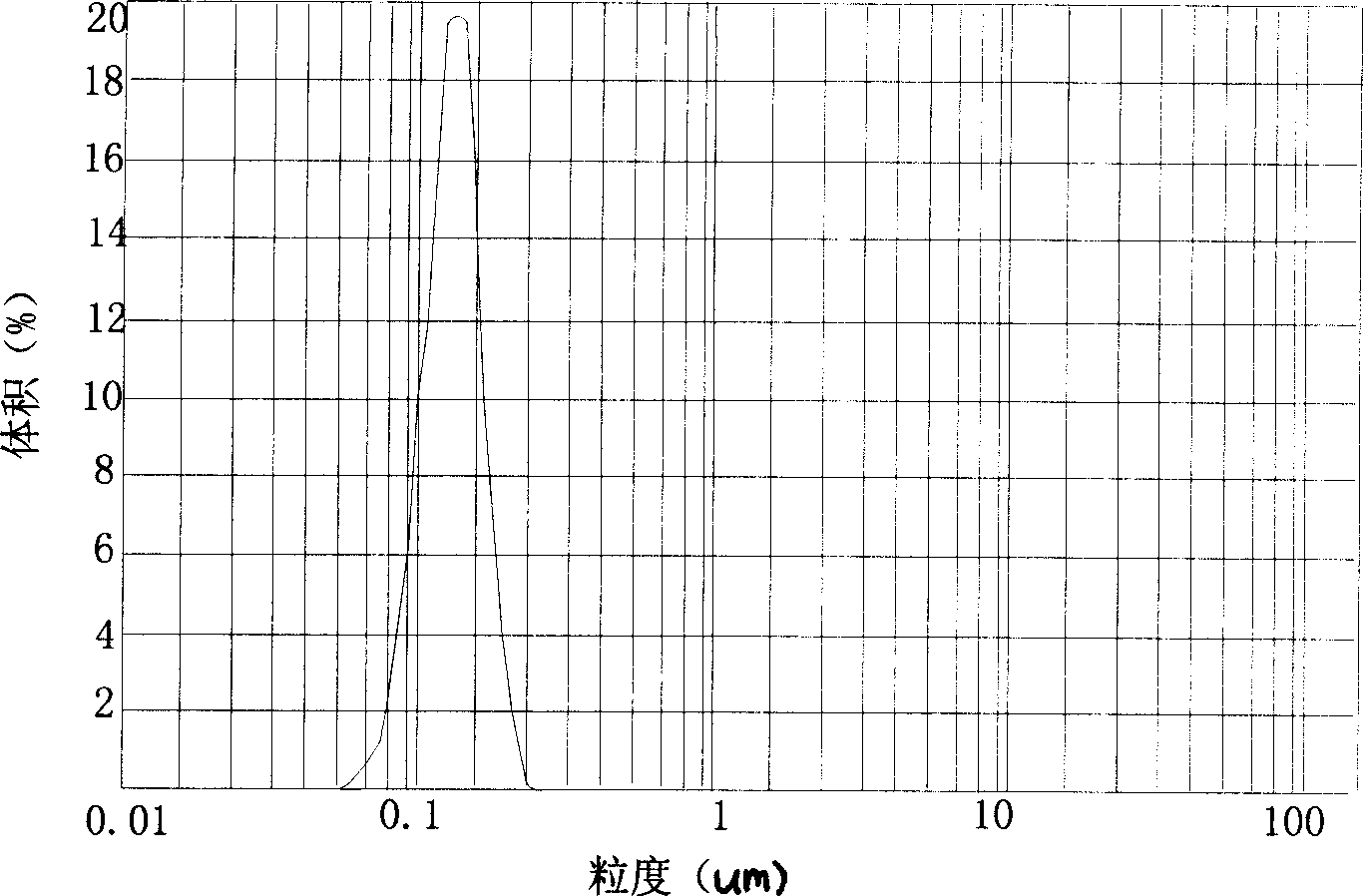

[0026] In the laboratory ball mill, adding montmorillonite content is 95% sodium bentonite water suspension (solid content is 4%, its particle size distribution is as follows: Figure 8 ) 500ml, stirred for 10 minutes, added 5mm diameter zirconia spherical beads with a volume of 200ml, ball milled for 5 hours at 100 rpm with a rotating speed, and got the superfine sodium-based bentonite slurry by taking the upper layer slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com