Spraying-free adhesive for plastic sucking PVC decorative film and preparation method thereof, plastic sucking plate and preparation method thereof

A glue spraying and decorative layer technology, applied in the direction of chemical instruments and methods, applications, adhesives, etc., can solve the problems of VOC reduction and low-temperature blister molding, etc., and achieve the effect of excellent high temperature resistance and high adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

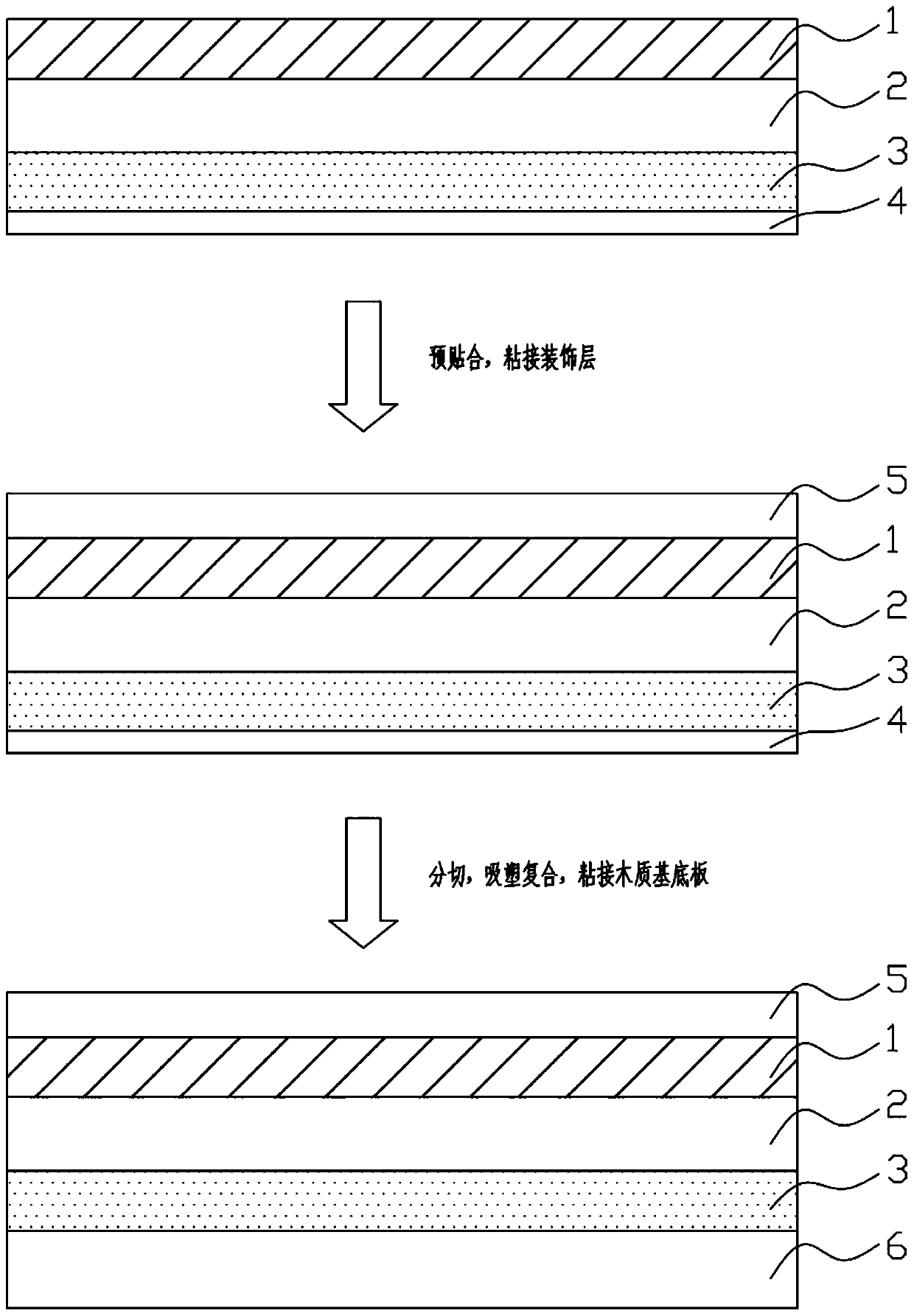

[0087] figure 2 It is a schematic flow diagram of the preparation process of the blister board provided by the embodiment of the present invention. like figure 2 As shown, the blister board includes spray-free glue, and a decorative layer 5 and a wooden base plate 6 respectively arranged on both sides of the spray-free glue, and the decorative layer 5 is attached to the spray-free glue-free A layer 1 , the wooden base plate 6 is attached to the glue-free C layer 3 .

[0088] Specifically, the decorative layer 5 may be a PVC decorative layer.

[0089] The preparation method of described blister board, comprises the steps:

[0090] Pre-laminate the decorative layer 5 on the surface of the spray-free A layer 1, if there is a release layer 4, first remove the release layer 4, and then plastic-composite the wooden base board 6 on the spray-free glue Layer 3 of C.

Embodiment 1

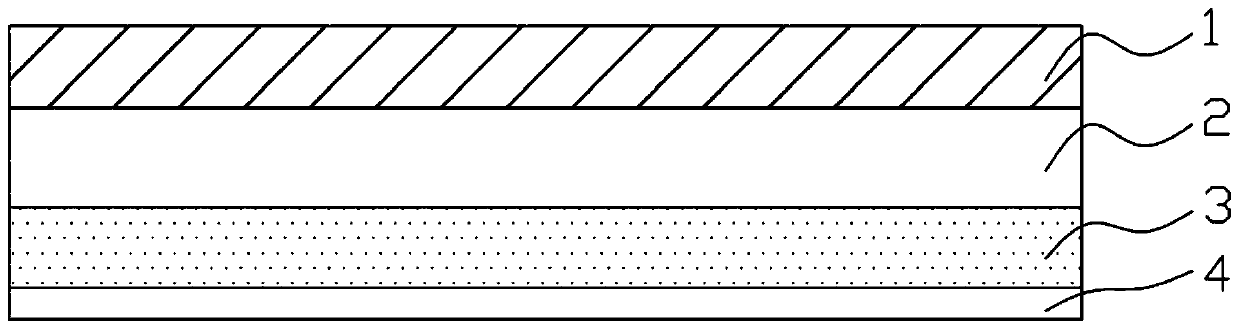

[0092] This embodiment provides a spray-free glue, its structure is as figure 1 As shown, wherein, the thickness of layer A is 0.03mm, the thickness of layer B is 0.02mm, and the thickness of layer C is 0.01mm.

[0093] The composition of spray-free glue is as follows (by weight percentage):

[0094] The components of layer A include:

[0095] Polyester (Guangzhou Qingtian Company, brand NH3306) 35%;

[0096] Copolyester (EMS-Griltech company, brand ES700) 10%;

[0097] Thermoplastic polyurethane (Wanhua Chemical Company, brand 6229C) 50%;

[0098] Neoprene (Nippon Denka Corporation, brand A120) 5%.

[0099] The components of layer B include:

[0100] Ethylene-acrylate-maleic anhydride terpolymer (Arkema company, brand 4700) 30%;

[0101] Ethylene-acrylate copolymer (Dupont company, brand 1330) 70%.

[0102] The components of layer C include:

[0103] Ethylene-vinyl acetate grafted maleic anhydride (Lushan New Material Company, brand OV-1) 15%;

[0104] Ethylene-vinyl...

Embodiment 2

[0113] This embodiment provides a spray-free glue, its structure is as figure 1 As shown, wherein, the thickness of layer A is 0.03mm, the thickness of layer B is 0.02mm, and the thickness of layer C is 0.01mm.

[0114] The composition of spray-free glue is as follows (by weight percentage):

[0115] The components of layer A include:

[0116] Polyester (Guangzhou Qingtian Company, brand NH3306) 30%;

[0117] Copolyester (EMS-Griltech company, brand ES700) 5%;

[0118] Thermoplastic polyurethane (Wanhua Chemical Company, brand 6229C) 55%;

[0119] Neoprene (Nippon Denka Corporation, brand A120) 10%.

[0120] The components of layer B include:

[0121] Ethylene-acrylate-maleic anhydride terpolymer (Arkema company, trade mark 4700) 35%;

[0122] Ethylene-acrylate copolymer (Dupont company, brand 1330) 65%.

[0123] The components of layer C include:

[0124] Ethylene-vinyl acetate grafted maleic anhydride (Lushan New Material Company, brand OV-1) 25%;

[0125] Ethylene-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com