Preparation method of polyacrylic acid thickener taking modified starch as cross-linking agent

A technology of polyacrylic acid and cross-linking agent, applied in the field of new materials, can solve the problems of high structural viscosity, difficult to remove paste with water, poor water retention, etc., and achieve the effect of improving electrolyte resistance and excellent thickening ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

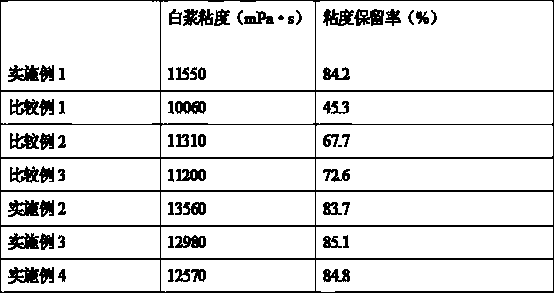

Examples

Embodiment 1

[0025] (1) Add soluble starch into a three-necked flask equipped with a stirrer and a reflux condenser, add a 50% NaOH aqueous solution under stirring conditions, and the ratio of its mass to the mass of soluble starch is 1:1 to completely dissolve the starch; Under the condition of 70°C and stirring, slowly add freshly steamed 3-bromo-1-propene dropwise from the dropping funnel, the ratio of its mass to the mass of soluble starch is 1:1, after the addition, heat up to 80°C, and stir Under the conditions of reaction for 4 hours, after the reaction was completed, cooled, added the same volume of deionized water, washed away sodium bromide, and separated the organic layer; the organic layer was washed twice with water, steam distilled until no volatiles were distilled, then added toluene, separated liquid to obtain a light yellow solution; dry with fresh anhydrous sodium sulfate, filter, and the filtrate is at 100 ° C, N 2 Under protection, vacuum distillation, completely remove...

Embodiment 2

[0040] (1) Add soluble starch into a three-necked flask equipped with a stirrer and a reflux condenser, add a 50% NaOH aqueous solution under stirring conditions, and the ratio of its mass to the mass of soluble starch is 2:1 to completely dissolve the starch; Under the condition of stirring at 75°C, slowly add freshly steamed 3-bromo-1-propene dropwise from the dropping funnel, the ratio of its mass to the mass of soluble starch is 2:1, after the addition, heat up to 85°C, and stir Under the condition of reaction for 2h, after the reaction was finished, cool down, add the same volume of deionized water, wash away the sodium bromide, separate the organic layer; wash the organic layer twice, steam distill until no volatile matter distilled, add toluene, separate liquid to obtain a light yellow solution; dry with fresh anhydrous sodium sulfate, filter, and the filtrate is at 100 ° C, N 2 Under protection, vacuum distillation, completely remove toluene, much allyl starch;

[004...

Embodiment 3

[0044] (1) Add soluble starch into a three-necked flask equipped with a stirrer and a reflux condenser, add a 50% NaOH aqueous solution under stirring conditions, and the ratio of its mass to the mass of soluble starch is 1.5:1 to completely dissolve the starch; Under the condition of stirring at 72°C, slowly add freshly steamed 3-bromo-1-propene dropwise from the dropping funnel, the ratio of its mass to the mass of soluble starch is 1.5:1, after the addition, heat up to 82°C, and stir Under the condition of reaction for 3h, after the reaction was finished, cool down, add the same volume of deionized water, wash away the sodium bromide, separate the organic layer; wash the organic layer twice, steam distill until no volatile matter distilled, add toluene, separate liquid to obtain a light yellow solution; dry with fresh anhydrous sodium sulfate, filter, and the filtrate is at 100 ° C, N 2 Under protection, vacuum distillation, completely remove toluene, much allyl starch;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com