A kind of anti-virus flexible transparent composite material and its products

A composite material and transparent technology, applied in the direction of synthetic resin layered products, protective clothing, protective equipment, etc., can solve the problems of high rigidity, non-foldable packaging, etc., achieve good barrier properties, and ensure the effect of composite fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

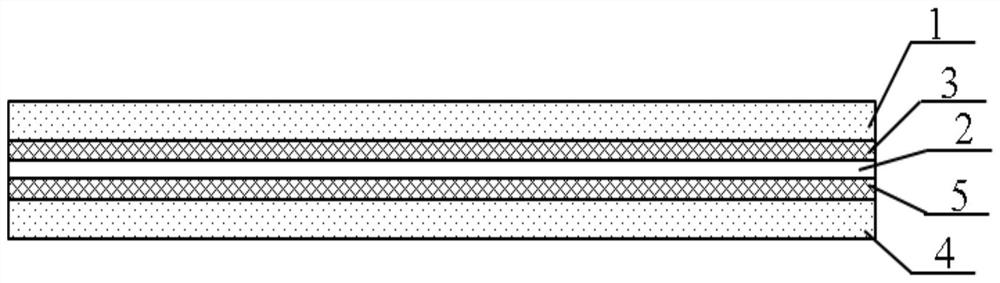

[0031] The anti-virus and flame-retardant flexible transparent composite material of this embodiment includes an inner protective layer 1, a resin film 3, a barrier layer 2, a resin film 5, and an outer protective layer 4 from the inside to the outside. For substances that can last for more than 72 hours, the protective layer is transparent, airtight and foldable. The transparent composite material has a protective time against mustard gas of more than 72 hours, a flame retardancy of UL94-V-0, and a light transmittance of 91.5%. The composite transparent material has good cold resistance. It can be folded in half at 180° at -40°C without cracking. It is light, soft and foldable.

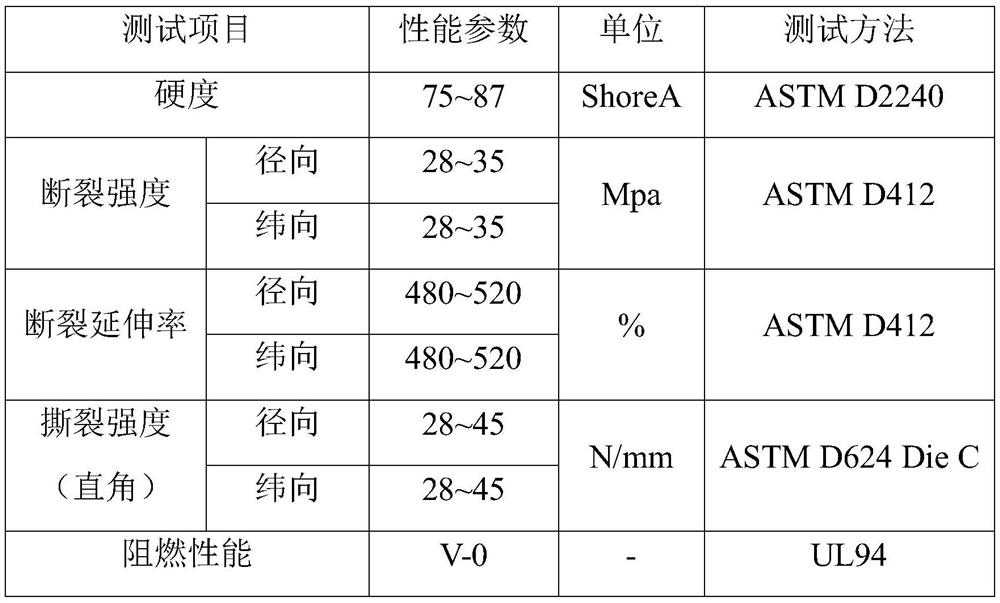

[0032] The inner protective layer 1 and the outer protective layer 4 of the present embodiment are all flame-retardant polyether thermoplastic polyurethane (TPU) elastomers, and the thicknesses are respectively 0.15mm and 0.2mm. The film has strong cold resistance, high transparency and smooth surfac...

Embodiment 2

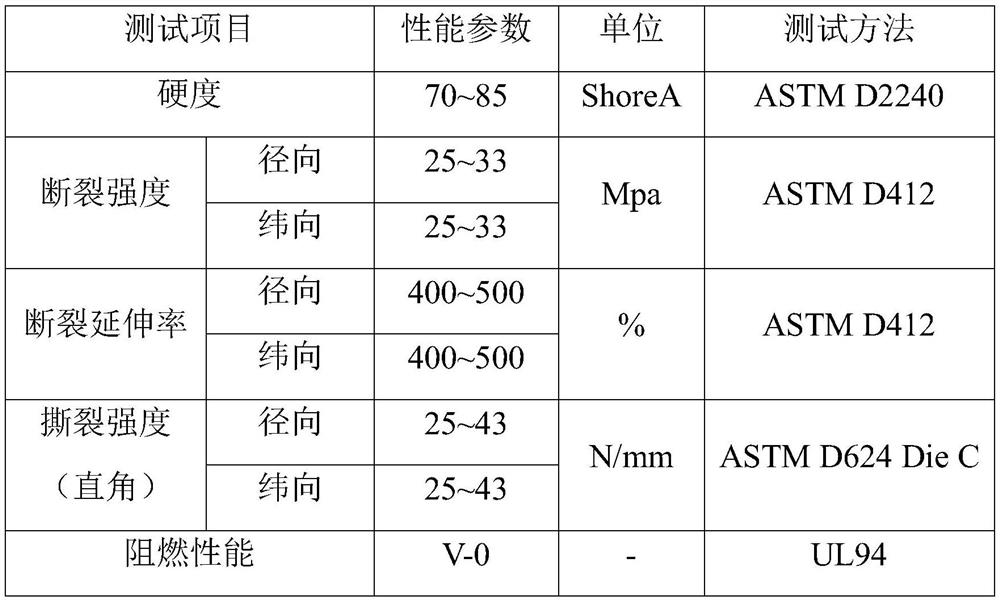

[0041] The composition of the composite material of this embodiment is the same as that of Embodiment 1, except that the inner and outer protective layers of this embodiment are polyvinyl chloride (PVC) films with thicknesses of 0.2 mm and 0.3 mm, respectively. The polyvinyl chloride material has high transparency, excellent chemical stability, and excellent anti-corrosion performance; the barrier layer is still a polyester (PET) film with a thickness of 0.025mm; the thickness of each layer of material is 0.15mm. Polyurethane (PU) optical film vacuum hot pressing compound.

[0042] The preparation method of the composite material in this example is the same as that in Example 1. The flame-retardant polyvinyl chloride film is prepared by tape casting, and the polyurethane optical film is used for vacuum hot-compression lamination. The lamination temperature is 90° C. and the pressure is 10 MPa.

[0043] The following is a list of polyvinyl chloride film requirements that are fe...

Embodiment 3

[0048] The inner and outer protective layers of the composite material in this embodiment are both flame-retardant polyethylene films, with thicknesses of 0.1 mm and 0.25 mm, respectively. The barrier layer is biaxially stretched nylon film with a thickness of 0.015mm. The polyethylene film material has light specific gravity, less dust absorption and high light transmittance.

[0049] The preparation method of the composite material in this example is composite processing of blow molding and hot pressing. The transparent flame-retardant polyethylene film was prepared by blow molding process, and then the 0.2mm flame-retardant ethylene-vinyl acetate copolymer optical film was used for vacuum hot-compression lamination. The lamination temperature was 95°C and the pressure was 9MPa.

[0050] The following is a list of possible polyethylene film properties in this embodiment.

[0051] Polyethylene film performance table

[0052]

[0053] The composite material prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com