Shearing mixing piece and vacuum mixer applying the same

A shear mixing and vacuum mixing technology, which is applied in mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve the problems of increasing mixing time, waste of raw materials, and increasing feeding time, and achieve full mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

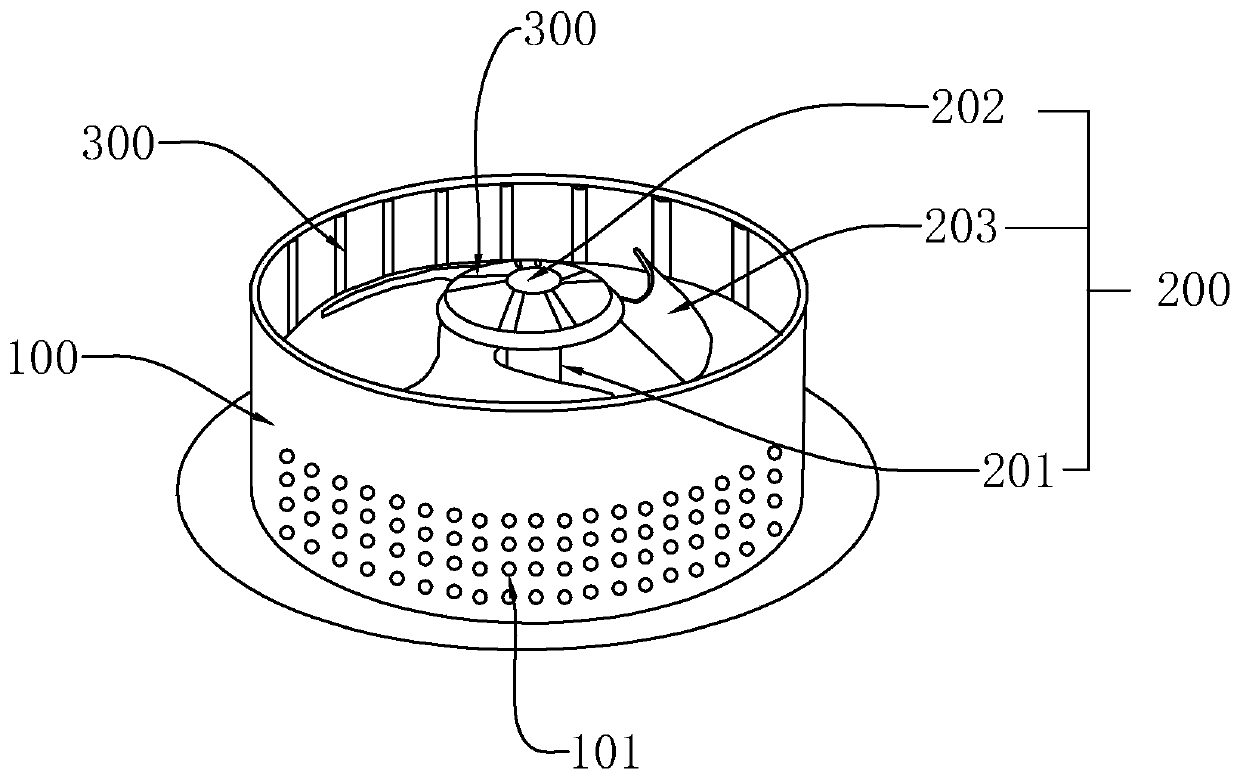

[0044] refer to figure 1, in order to achieve rapid shear mixing, a shear mixing element is provided, including a stator part 100 and a rotor part 200, the stator part 100 is sleeved on the outside of the rotor part 200 and fixed to each other, and the highest end of the rotor part 200 is lower than the stator part At the highest end of 100 , both the stator part 100 and the rotor part 200 are provided with spoilers 300 . The rotor part 200 is located inside the stator part 100, and the rotor part 200 runs at high speed to further break up the added powder, making it quickly dissolve in the liquid, and the stator part 100 further disturbs the solid-liquid mixture, further improving the dissolution effect. The spoiler part 300 is arranged on the inner peripheral surface of the stator part 100 , and a plurality of spoiler passage holes 101 are provided on the body of the stator part 100 . Under the high-speed agitation and shearing of the rotor part 200, the powder-liquid mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com