Microwave drying device with power self-adaptive adjustment

An adaptive adjustment and microwave drying technology, which is applied in the direction of heating devices, drying solid materials, heating to dry solid materials, etc., can solve the problems that it is difficult to completely remove water in nano-pattern structures, wafer scrapping, structure blowing collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

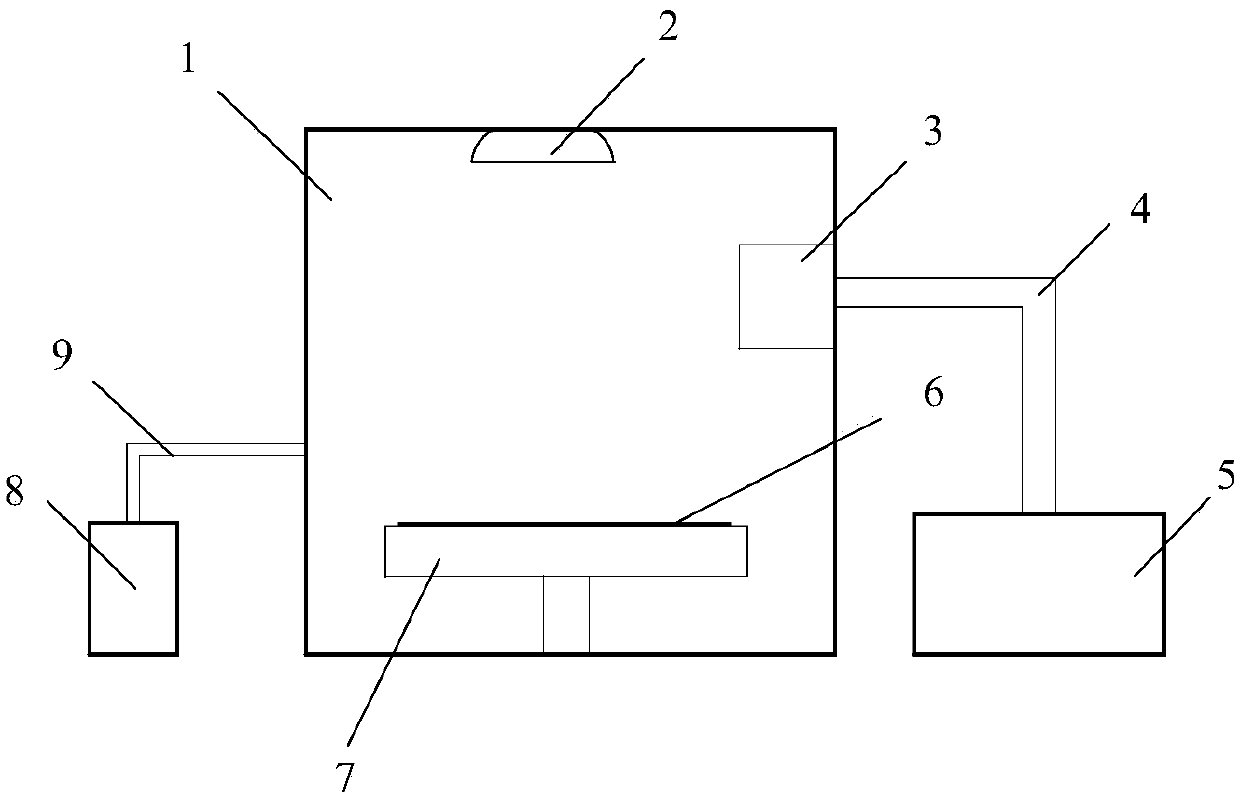

[0019] see figure 1 , a microwave drying device with self-adaptive power adjustment provided by an embodiment of the present invention includes a cavity 1, an ultraviolet curing lamp 2, a microwave coupling matcher 3, a microwave transmission wire 4, a microwave power source 5, a wafer 6, a carrier Chip stage 7, vacuum pump group 8 and conduit 9.

[0020] Wherein, the cavity 1 is generally made of aluminum material, and pure aluminum or aluminum alloy material can be used.

[0021] On the side wall of the cavity 1, a microwave coupling matching device 3 is arranged, and the microwave power source 5 outside the cavity 1 is connected to the microwave coupling matching device 3 through a microwave transmission wire 4, and the microwave power is delivered to the microwave coupling matching device 3 , The microwave coupling matcher 3 includes a microwave antenna, an impedance matching network and a microwave detector. The microwave antenna is used to apply microwave power to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com