Method for preparing synthesis gas from biomass and system adopted by method

A biomass and synthesis gas technology, applied in the direction of biofuel, combustible gas production, special form of dry distillation, etc., can solve the problems of high overall cost, limited application, and high tar generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

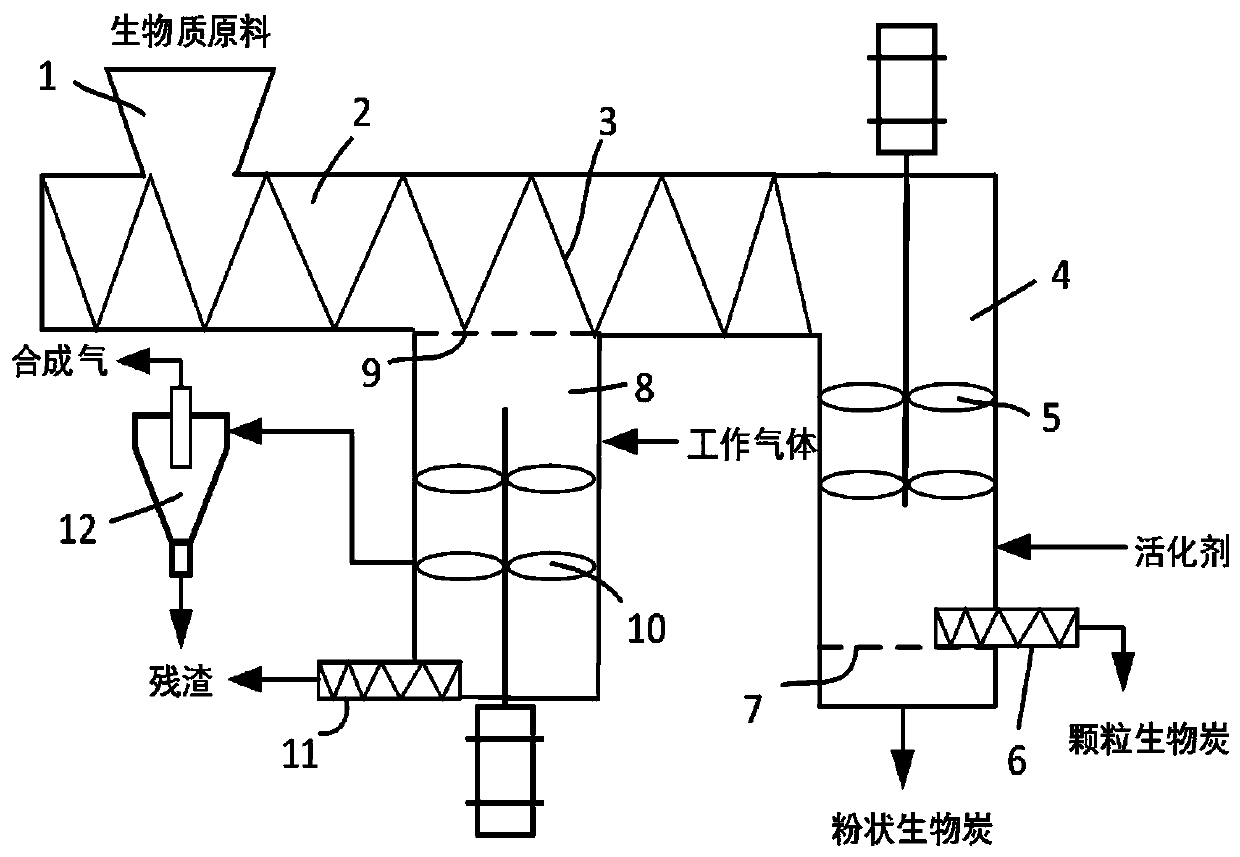

Image

Examples

Embodiment 1

[0051] The dried biomass is heated to 180°C under the action of high-temperature airflow, and the holding time is 10 minutes, then cooled and crushed to less than 5mm, mixed according to the mass ratio of biomass to biochar of 1:0.1, and then heated at 15MPa By physical extrusion molding, a biomass raw material with a maximum dimension of 10 mm is obtained, and the gas generated during the preheating process is preheated gas I.

[0052] The above-mentioned biomass raw materials are sent into a microwave pyrolysis reactor, and the pyrolysis temperature is 800°C, the pyrolysis time is 15 minutes, and the microwave power density is 0.5×10 5 W / m 3 Under these conditions, gaseous pyrolysis volatiles and bio-coke were obtained, of which pyrolysis volatile components accounted for 70%, and bio-coke accounted for 30%. The gasification temperature is 850°C, the reaction time is 20 minutes, and the flow rate of the activator is 1m 3 / h (the mass ratio of preheated gas to water vapor i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com