Self-adhesive functional composite film and preparation method thereof

A composite film, functional technology, applied in the direction of adhesive types, rosin adhesives, ester copolymer adhesives, etc., can solve the problems of high volatility, complex production process, high pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

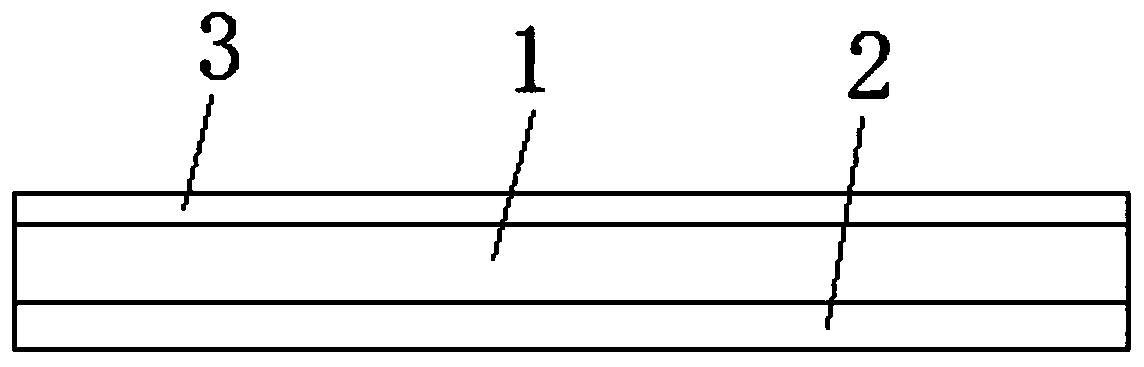

[0058] On the white PE film (light transmittance 3%) of 25 μ m thick, about 4A size, use 5 roller coating mode to coat about 0.5 μ m of silicon release agent, under voltage 110KV, 30KGy irradiation dose and nitrogen gas, EB curing; The other side of the PE film is coated with EB glue A with a thickness of 30 μm, and the EB is cured under a voltage of 150KV, a radiation dose of 50KGy and nitrogen to obtain a white self-adhesive functional film A without a hardened layer.

Embodiment 2

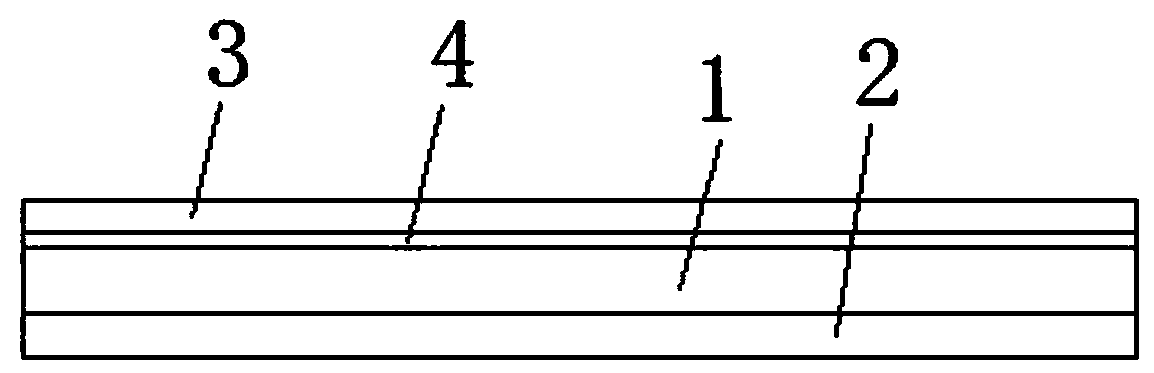

[0060]Flexographically print black and white stripe patterns on a transparent PET sheet with a thickness of 100 μm, the thickness of the ink layer is about 8 μm, and the EB is cured at a voltage of 130KV, an irradiation dose of 30KGy and nitrogen, and the adhesion of the color block to the PET sheet is detected by the cross-hatch method It is level 0 (best level); roll-coat 5 microns of hardener on the ink layer, and cure with EB at a voltage of 110KV, an irradiation dose of 25KGy and nitrogen to obtain a hardened layer with a hardness of about 4H; roll-coat on the hardened layer About 0.4μm fluorine release agent, and EB curing under voltage 110KV, radiation dose 20KGy and nitrogen; 40μm EB pressure-sensitive adhesive B is coated on the back of PET sheet, and the voltage is 160KV, radiation dose 60KGy and nitrogen The lower EB is cured to obtain a self-adhesive functional film B with a release layer, a hardened layer, and black and white patterns.

Embodiment 3

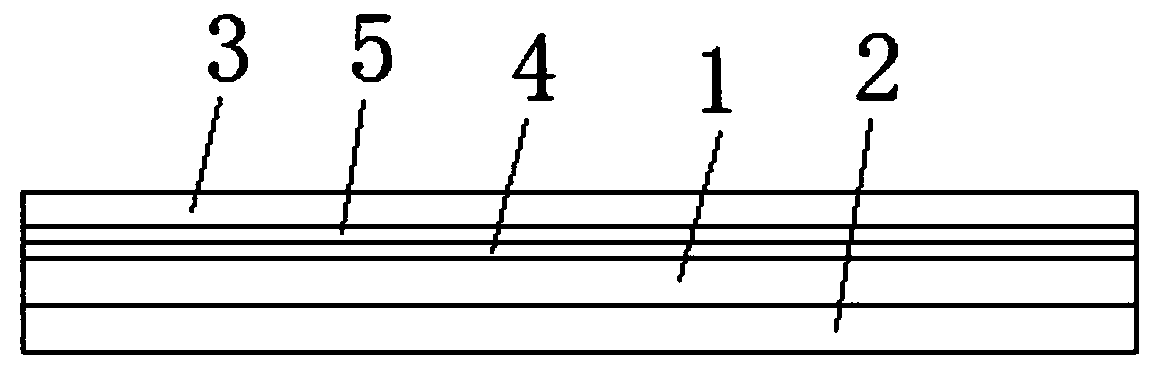

[0062] Print the pattern of black and blue alternate stripes on a white PET sheet with a thickness of 180 μm. The thickness of the ink layer is about 6 μm. When the voltage is 120KV, the radiation dose is 30KGy and the nitrogen is cured by EB, the adhesion of the pattern color block to the PET sheet is 0; Coat the 5μm hardener with matte powder on the layer, and EB cure at a voltage of 110KV, an irradiation dose of 25KGy and nitrogen, and the hardness of the hardened layer is about 4H; a 60μm UV glue is coated on the back of the PET sheet and used After covered with PE release film, it is irradiated and cured by a crawler-type light curing machine equipped with 2x1000W mercury lamps, and the exposure energy is 1000J / cm 2 , get the self-adhesive functional film C of the matte blue-black pattern of release film protection.

[0063] The self-adhesive functional film A of embodiment 1 and the self-adhesive functional film B of embodiment 2 are both self-adhesive functional films w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com