Hybrid dynamic polymer

A technology of hybridization and polymers, applied in the field of intelligent polymers, can solve problems such as weak dynamics and difficult practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

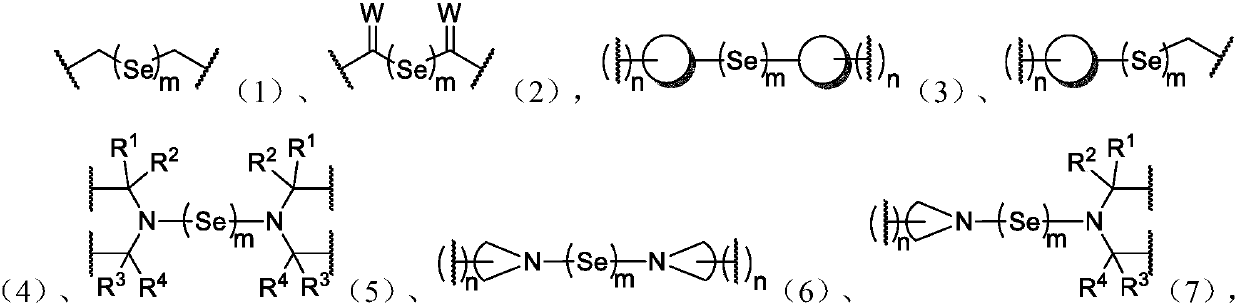

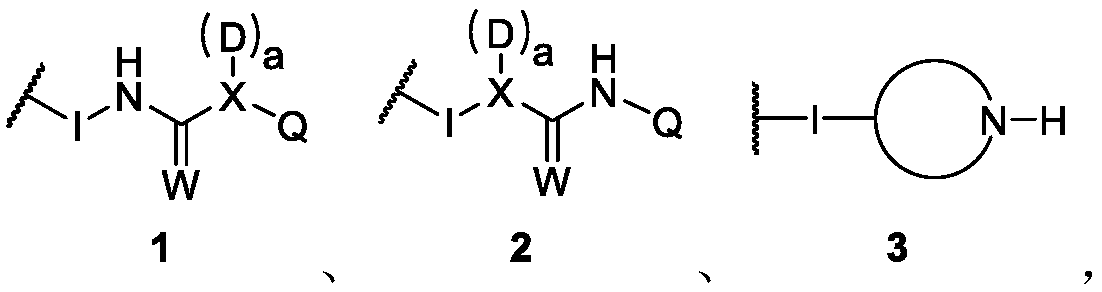

Method used

Image

Examples

preparation example Construction

[0176] In the preparation process of dynamic polymer foam materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0177] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0178] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under press...

Embodiment 1

[0244] Under the protection of nitrogen, 1 mass part of selenium powder was added to 50 mass parts of aqueous solution dissolved with 1 mass part of sodium borohydride, stirred for 10 min under magnetic stirring, then 1 mass part of selenium powder was added, and after continuing to stir for 15 min, slowly Raise the temperature until the selenium powder is completely dissolved to obtain a brown-red aqueous solution of sodium selenide; the aqueous solution of sodium selenide is transferred to a single-necked flask and sealed with a rubber stopper; A part of tetrahydrofuran solution was injected into a sealed single-necked flask under nitrogen protection, reacted at 50°C for 6h, then extracted three times with dichloromethane, and dried with anhydrous sodium sulfate to obtain a yellow transparent liquid bis-hydroxyethyl diselenide; 4.2 parts by mass of 1,6-hexamethylene diisocyanate and 0.01 molar equivalent of triethylamine were added to reactor No. 1, and after the temperature ...

Embodiment 2

[0246] Under the protection of nitrogen, 1 mass part of selenium powder was added to 50 mass parts of aqueous solution dissolved with 1 mass part of sodium borohydride, stirred for 10 min under magnetic stirring, then 1 mass part of selenium powder was added, and after continuing to stir for 15 min, slowly Raise the temperature until the selenium powder is completely dissolved to obtain a brownish-red aqueous solution of sodium selenide; the aqueous solution of sodium selenide is transferred to a single-necked flask and sealed with a rubber stopper; Parts by mass of THF solution were injected into a sealed single-necked flask under nitrogen protection, reacted at 50°C for 6h, then extracted three times with dichloromethane, and dried with anhydrous sodium sulfate to obtain diamine ethyl diselenide; in No. 1 In the reactor, get 1 molar equivalent of sodium alginate and dissolve it in a sufficient amount of deionized water, then add 0.5 molar equivalent of NaIO 4 , after stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com