Synthetic method of propiolic acid

A synthesis method and technology of propynoic acid, applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation and other directions, can solve the problems of high price of propargyl alcohol, high production process cost, unfriendly environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

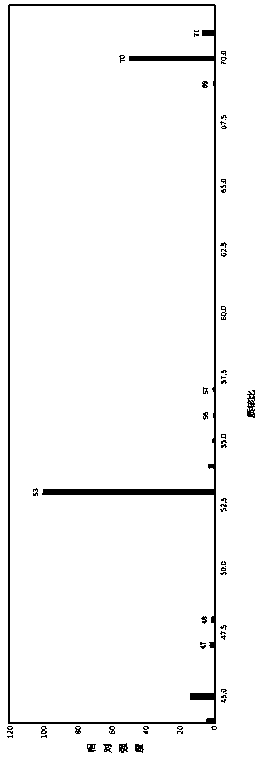

Image

Examples

Embodiment 1

[0027] Put 160ml (3mol) of acetonitrile, 53g (0.5mol) of sodium carbonate and 54g (0.5mol) of phenolic resin microspheres into the reaction kettle and stir evenly. Then 32g (0.5mol) of calcium carbide and 7.9g (3%) of cuprous iodide were added to the reactor, and the reactor was filled with carbon dioxide. Heat and pressurize the reaction. Reaction temperature is 60 ℃, and reaction pressure is 2MPa. The reaction time was 18 hours. After the reaction, the mixture was filtered to separate the liquid, and then acidified with sulfonic acid resin to obtain the product. The product was analyzed by liquid chromatography, and the yield of propiolic acid was 96 mol%.

Embodiment 2

[0029] Put 320ml (6mol) of acetonitrile, 27g (0.25mol) of sodium carbonate and 27g (0.25mol) of phenolic resin microspheres into the reaction kettle and stir evenly. Then 16g (0.25mol) of calcium carbide and 5.9g (3%) of cuprous iodide were added to the reactor, and the reactor was filled with carbon dioxide. Heat and pressurize the reaction. Reaction temperature is 60 ℃, and reaction pressure is 2MPa. The reaction time was 18 hours. After the reaction, the mixture was filtered to separate the liquid, and then acidified with sulfonic acid resin to obtain the product. The product was analyzed by liquid chromatography, and the yield of propiolic acid was 95% mol.

Embodiment 3

[0031] Put 160ml (3mol) of acetonitrile, 159g (0.75mol) of sodium carbonate and 162g (0.75mol) of phenolic resin microspheres into the reaction kettle and stir evenly. Then add 96g (0.75mol) of calcium carbide and 10g (1.5%) of cuprous iodide into the reactor, and fill the reactor with carbon dioxide. Heat and pressurize the reaction. Reaction temperature is 60 ℃, and reaction pressure is 2MPa. The reaction time was 18 hours. After the reaction, the mixture was filtered to separate the liquid, and then acidified with sulfonic acid resin to obtain the product. The product was analyzed by liquid chromatography, and the yield of propiolic acid was 97 mol %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield | aaaaa | aaaaa |

| Yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com