Solid acid catalyst and preparation method and application thereof in esterification transesterification

A solid acid catalyst, a technology for transesterification, which is used in catalyst activation/preparation, fatty acid esterification, chemical instruments and methods, etc., and can solve the problems of difficult recovery and regeneration, environmental pollution, and insufficient activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

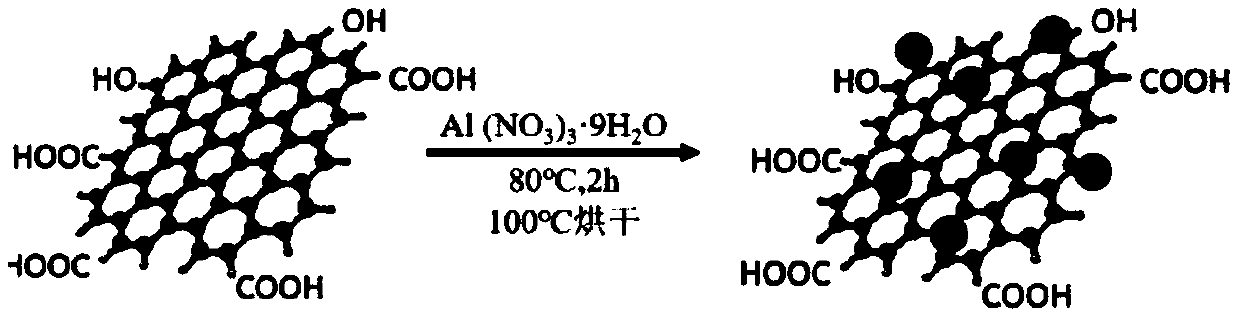

[0036] Take quantitative graphene oxide suspension, weigh quantitative Al after ultrasonic 2 (SO 4 ) 3 9H 2 O was added to the GO suspension, and the mass ratio of graphene oxide to alumina in the product was controlled to be 2:1. After stirring evenly, the pH of the mixture was adjusted to about 7, and stirred at a constant temperature of 80°C for 2 hours. Take out the mixture and cool it down and leave it to age for 10 hours, filter and dry to obtain the aluminum oxide graphene nanocomposite material, denoted as GA 21 .

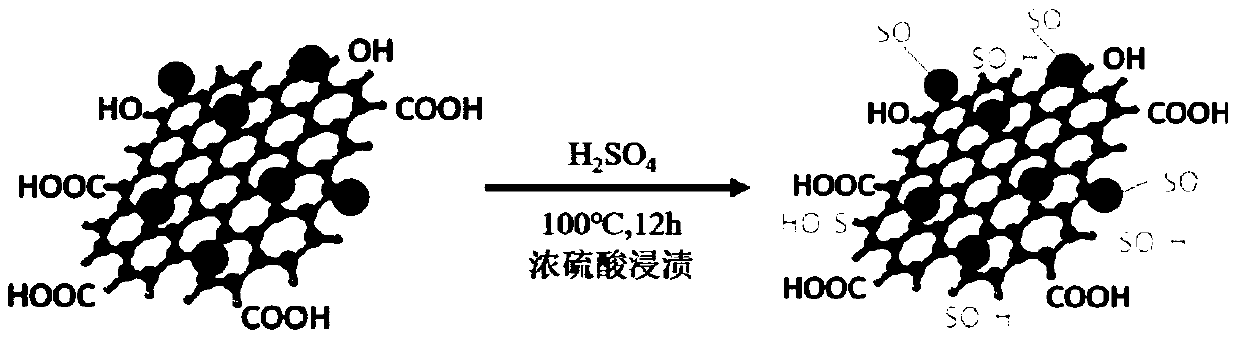

[0037] The above GO-Al 2 o 3 The nanocomposite material was impregnated by adding concentrated sulfuric acid in an amount of 100mg / mL, stirred evenly, ultrasonicated for 30 minutes, and reacted at 100°C for 12 hours, and the Al 2 o 3 Sulfation of GO and sulfonation of GO, filtered, washed and dried to obtain a solid acid catalyst, denoted as GAS 21 .

Embodiment 2

[0039] Take quantitative graphene oxide suspension, weigh quantitative Al after ultrasonic 2 (SO 4 ) 3 9H 2 O was added to the GO suspension, and the mass ratio of graphene oxide to alumina in the product was controlled to be 3:1. After stirring evenly, the pH of the mixture was adjusted to about 7, and stirred at a constant temperature of 80°C for 2 hours. Take out the mixture and cool it down and leave it to age for 10 hours, filter and dry to obtain the aluminum oxide graphene nanocomposite material, denoted as GA 31 .

[0040] The above GO-Al 2 o 3 The nanocomposite material was impregnated by adding concentrated sulfuric acid in an amount of 100mg / mL, stirred evenly, ultrasonicated for 30 minutes, and reacted at 100°C for 12 hours, and the Al 2 o 3 Sulfation of GO and sulfonation of GO, filtered, washed and dried to obtain a solid acid catalyst, denoted as GAS 31 .

Embodiment 3

[0042] Take quantitative graphene oxide suspension, weigh quantitative Al after ultrasonic 2 (SO 4 ) 3 9H 2 O was added to the GO suspension, and the mass ratio of graphene oxide and alumina in the product was controlled to be 4:1. After stirring evenly, the pH of the mixture was adjusted to about 7, and stirred at a constant temperature of 80°C for 2 hours. Take out the mixture and cool it down and leave it to age for 10 hours, filter and dry to obtain the aluminum oxide graphene nanocomposite material, denoted as GA 41 .

[0043] The above GO-Al 2 o 3 The nanocomposite material was impregnated by adding concentrated sulfuric acid in an amount of 100mg / mL, stirred evenly, ultrasonicated for 30 minutes, and reacted at 100°C for 12 hours, and the Al 2 o 3 Sulfation of GO and sulfonation of GO, filtered, washed and dried to obtain a solid acid catalyst, denoted as GAS 41 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com