Lithium-sulfur diaphragm with synergistic effect mechanism, preparation method of lithium-sulfur diaphragm and lithium-sulfur battery

A synergistic and diaphragm technology, applied in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of affecting charge balance, reducing Coulomb efficiency, poor electrical conductivity, etc., to suppress shuttle, improve cycle effect, The effect of cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned synergistic mechanism lithium-sulfur diaphragm of the present invention comprises the following steps:

[0044] Step 1. Prepare positive side functional layer 1 slurry

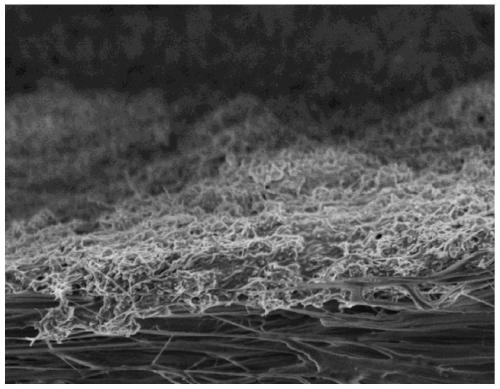

[0045] Disperse the porous conductive carbon material and the corresponding dispersant in a mixed solvent, and perform sand milling or ultrasonic treatment for 2-4 hours to obtain a porous conductive carbon material dispersion. Scanning with an electron microscope, the carbon material forms a porous conductive network structure; take quantitative Add the corresponding dispersant to the porous conductive dispersion liquid, and then perform mechanical stirring, the stirring time is 15-30min, the rotating speed is 800-1500r / min, preferably 900-1200r / min, and the stirring temperature is 15-30°C; After stirring the system to a uniform state, add the corresponding binder and surfactant to it, and then perform mechanical stirring. The stirring time is 30-90min, pre...

Embodiment 1

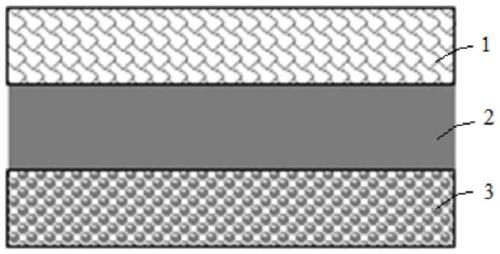

[0054]A lithium-sulfur separator with a synergistic mechanism in this embodiment includes a separator base film 2 and a positive electrode side functional layer 1 and a negative electrode side functional layer 3 respectively coated on both sides of the separator base film 2 . The components of the positive electrode side functional layer 1 include a porous conductive carbon material, a dispersant, a binder, a surfactant, and a mixed solvent. Specifically, the porous conductive carbon material is spherical carbon nanotubes, and its addition amount is 0.5% of the total weight of the side functional layer 1; the dispersant is polyvinyl alcohol, and its addition is 4.5% of the total weight of the positive side functional layer 1; the binder is polyacrylic acid, and its addition is the positive side functional layer 1. 7.5% of the total weight of layer 1; the surfactant is fatty alcohol polyoxyethylene ether, and its addition amount is 7.5% of the total weight of the positive electr...

Embodiment 2

[0063] A lithium-sulfur separator with a synergistic mechanism in this embodiment includes a separator base film 2 and a positive electrode side functional layer 1 and a negative electrode side functional layer 3 respectively coated on both sides of the separator base film 2 . The components of the positive electrode side functional layer 1 include a porous conductive carbon material, a dispersant, a binder, a surfactant, and a mixed solvent. Specifically, the porous conductive carbon material is conductive graphene oxide, and its addition amount is 20% of the total weight of the side functional layer 1; the dispersant is polyvinylpyrrolidone, and its addition is 5% of the total weight of the positive side functional layer 1; the binder is polyvinyl alcohol, and its addition is 5% of the positive side functional layer 1. 10% of the total weight of the functional layer 1; the surfactant is alkylphenol polyoxyethylene ether, and its addition amount is 5% of the total weight of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com