Welding method of thick-walled closed ring

A welding method and a closed-loop technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high processing pass rate and welding defects, and achieve the effects of convenient assembly and positioning, reducing processing costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

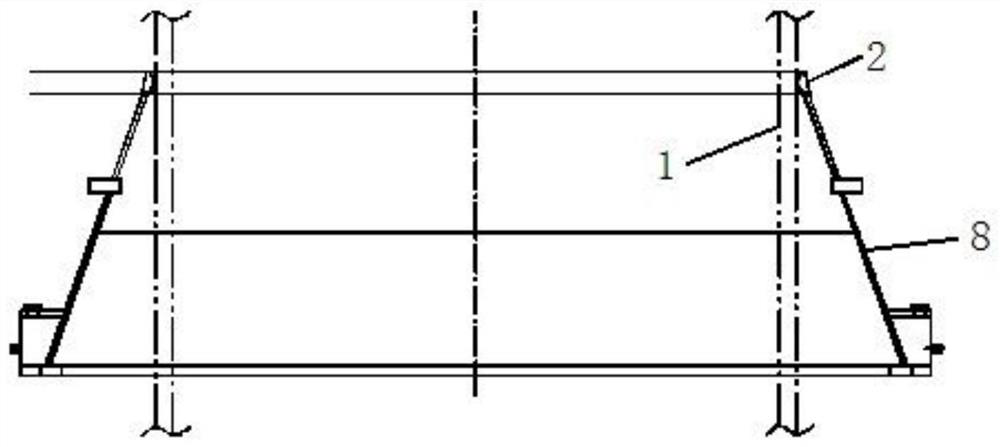

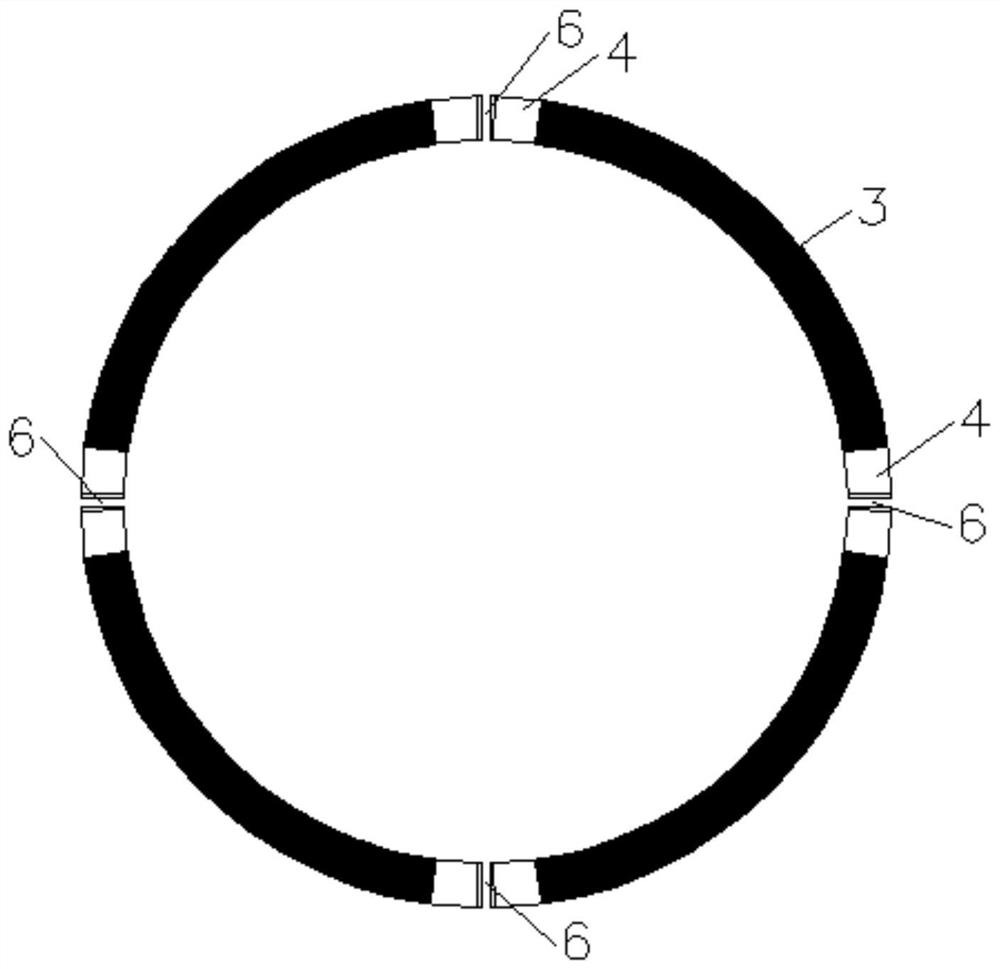

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the methanol synthesis tower produced by a workshop of the applicant is taken as an example. During the structural design of the tower, the skirt and the cylindrical shell are connected by welding rings. The shell and welding ring are made of SA-387GR22CL2, the outer diameter of the cylinder is about 4500mm, the thickness of the welding ring is δ70-90mm, and the width is 160mm. The welding process is as follows.

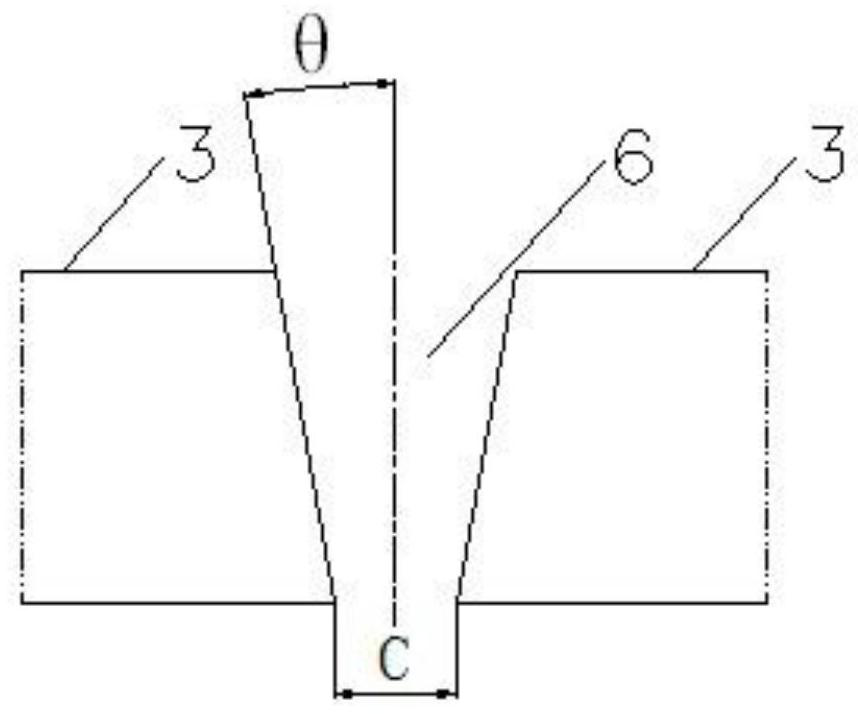

[0046] The welding ring is divided into four equal parts for blanking: divided into four arc segments 3, the two ends of the arc segment 3 are opened with a butt joint groove 6, and the form of the butt joint groove 6 is V-shaped, 20°;

[0047] Assembling the welding ring and the shell: the four arc segments 3 that make up the welding ring are assembled with the shell and fixed with a U-shaped plate, and the U-shaped plate is processed by CNC gas cutting. Each arc s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com