Steel ladle castable taking alumina-based homogenized material as matrix

A ladle pouring and homogenizing material technology, which is applied in the field of refractory castables, can solve problems such as loss of product quality stability, pits at the bottom of the ladle, poor materials, etc., and achieve the effect of improving the overall anti-corrosion performance and the overall age of the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

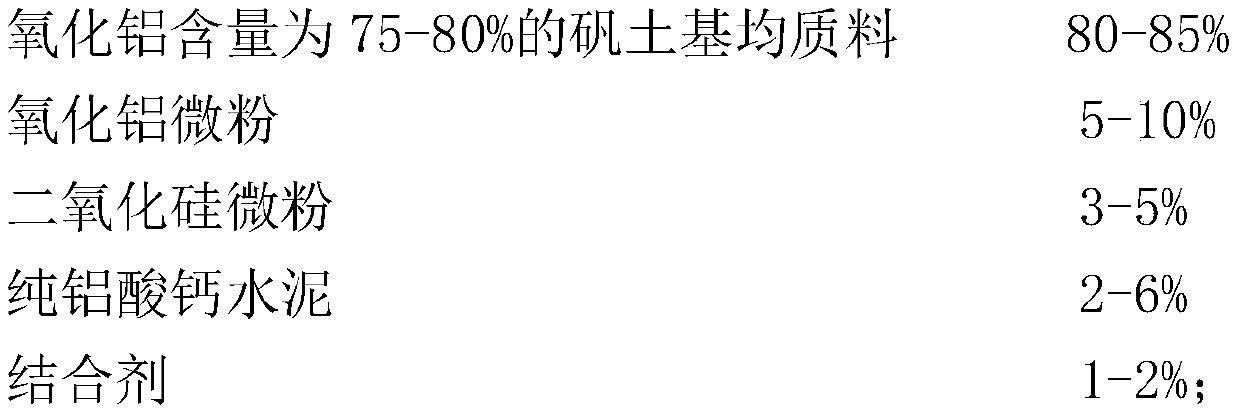

[0023] A ladle castable based on alumina-based homogenized material, prepared according to the following mass percentages:

[0024]

[0025] The content of particle gradation 8mm < particle size ≤ 25mm in bauxite-based homogeneous material shall not exceed 5%;

[0026] The particle size of the binder is controlled below 1mm.

[0027] Wherein: the mass content of iron oxide in the bauxite-based homogeneous material with an alumina content of 75-80% is 1.47%.

[0028] The particle size of alumina fine powder is 80-120 mesh.

[0029] The particle size of silica micropowder is 0.1-0.5 micron.

[0030] Pure calcium aluminate cement Calcium aluminate cement with an alumina content of 58-72%.

[0031] The homogenized synthetic material is produced by controlling the feed composition, grading storage, uniform distribution, fine material blending, wet grinding, concentrated filter press, vacuum extrusion, drying, high-temperature calcination, crushing and grading.

Embodiment 2

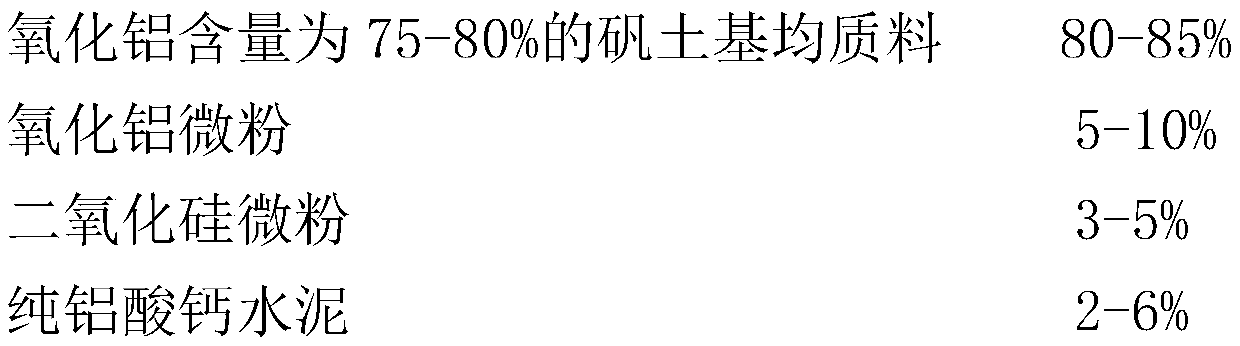

[0033] A ladle castable based on alumina-based homogenized material, prepared according to the following mass percentages:

[0034]

[0035] The content of particle gradation 8mm<particle size≤25mm in the alumina-based homogeneous material does not exceed 5%;

[0036] The particle size of the binder is controlled below 1 mm.

[0037] Wherein, the mass content of iron oxide in the alumina-based homogeneous material with an alumina content of 75-80% is 1.35%.

[0038] The particle size of alumina fine powder is 80-120 mesh.

[0039] The particle size of silica micropowder is 0.1-0.5 micron.

[0040] Pure calcium aluminate cement Calcium aluminate cement with an alumina content of 58-72%.

Embodiment 3

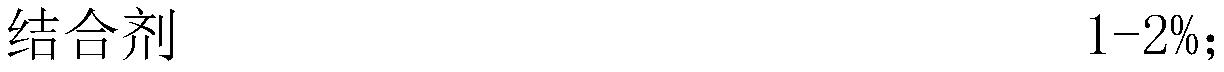

[0042] A ladle castable based on alumina-based homogenized material, prepared according to the following mass percentages:

[0043]

[0044] The content of particle gradation 8mm<particle size≤25mm in the alumina-based homogeneous material does not exceed 5%;

[0045] The particle size of the binder is controlled below 1 mm.

[0046] Wherein, the mass content of iron oxide in the alumina-based homogeneous material with an alumina content of 75-80% is 1.45%.

[0047] The particle size of alumina fine powder is 80-120 mesh.

[0048] The particle size of silica micropowder is 0.1-0.5 micron.

[0049] Pure calcium aluminate cement Calcium aluminate cement with an alumina content of 58-72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com