A kind of slag removal device for ladle

A ladle and slag sticking technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of easily broken bricks at the slag line, reduced ladle age, and labor intensity of workers, etc. Substantial features, improved package age, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

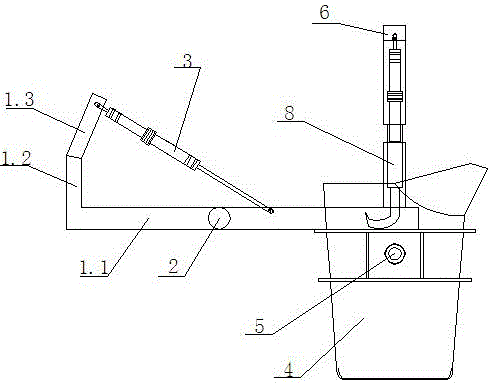

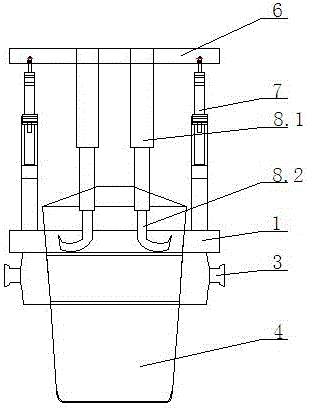

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0018] As can be seen from the accompanying drawings, a slag removing device for a ladle includes a compacting mechanism for compacting the ladle body 4 and a hook slag mechanism for removing sticky slag in the ladle 4, the compacting mechanism Including a rotating bracket 1, the rotating bracket 1 is composed of at least two arms fixedly connected, and the arms located at both ends of the rotating bracket 1 are respectively hingedly connected with the cylinder rod and the cylinder body of the rotating oil cylinder 3. When working, one end of the rotating bracket 1 The support arm is pressed on the trunnion seat 5 of the ladle 4, thereby the ladle 4 is fixed in the cleaning pit; in the present invention, the first support arm 1.1, the second support arm 1 and the second support arm of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com