A device for measuring the internal dimensions of a steel ladle using a laser range finder and its operating method

A technology of laser range finder and internal size, applied in the field of steelmaking, can solve the problems of requiring 4 to 5 people to operate at the same time, high daily maintenance cost, cumbersome measuring equipment, etc., to save refractory material consumption, easy operation and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0086] Basic parameters of laser range finder

[0087] Equipment Name Shendawei Laser Rangefinder Equipment Model SW—S50 Maximum Measurement Unit 50m Minimum Measurement Unit 1mm Measurement Accuracy ±1.5mm Inclination Angle Measurement Range ±90° Inclination Angle Measurement Error ±1.5° Laser Wavelength 635nm

[0088] Can accurately measure the distance from the measuring point to the target.

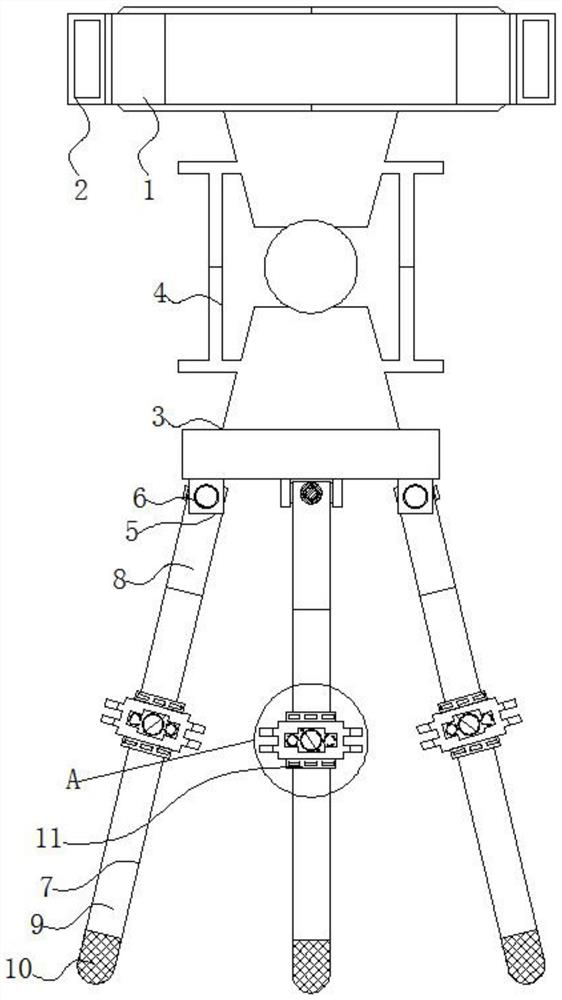

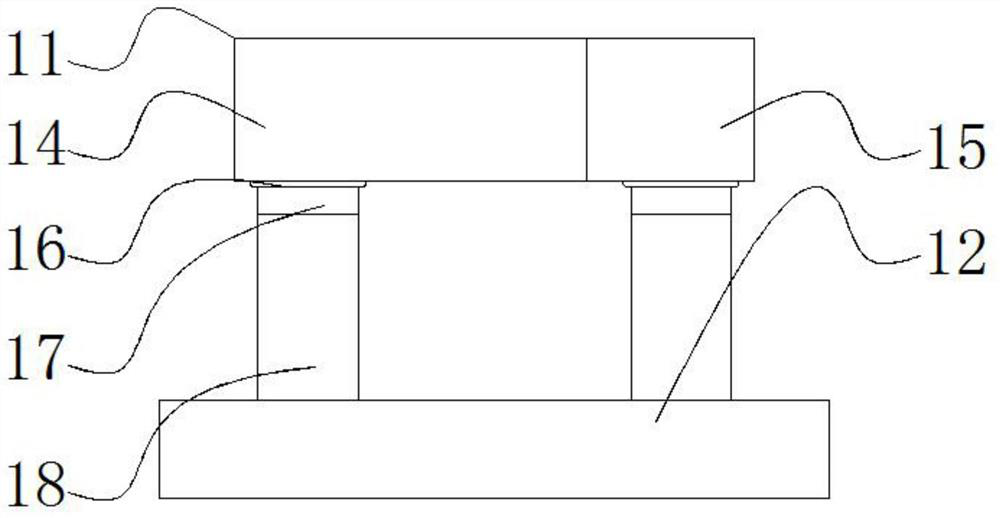

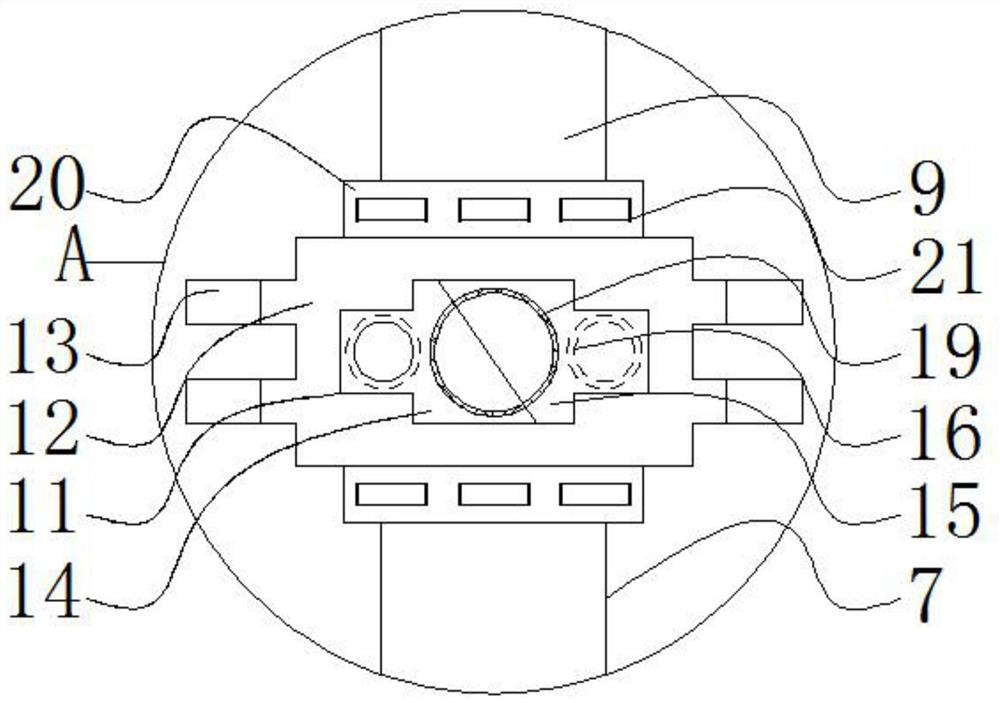

[0089] Basic parameters of tripod

[0090] Due to the poor stability of hand-held measurement, after the measurement center point is positioned, it cannot be saved for continuous measurement at this position, so a tripod is used instead of hand-held measurement. The measurement stability of the tripod is high, and the center point of the positioning measurement is always saved in this position, and there is no deviation.

[0091] 2D pan / tilt protractor

[0092] Equipment name Kaivisi double panorama clip professional two-dimensional head equipment model VH-10R material high-quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com