Method for preparing multi-grain-size heterogeneous aluminum alloy plate through composite rolling

An aluminum alloy plate and aluminum alloy technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of adverse effects of interface bonding, small thickness of composite sheets, and easy oxidation of the bonding interface, achieving good strength, high manufacturing accuracy, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] With reference to each accompanying drawing, the embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention does not Limited to the following examples.

[0024] The present invention takes an aluminum alloy plate as an example to give detailed implementation and specific operations. The following examples involve four steps including: surface rolling deformation, uniform annealing treatment, non-uniform rolling deformation and recrystallization annealing treatment, wherein :

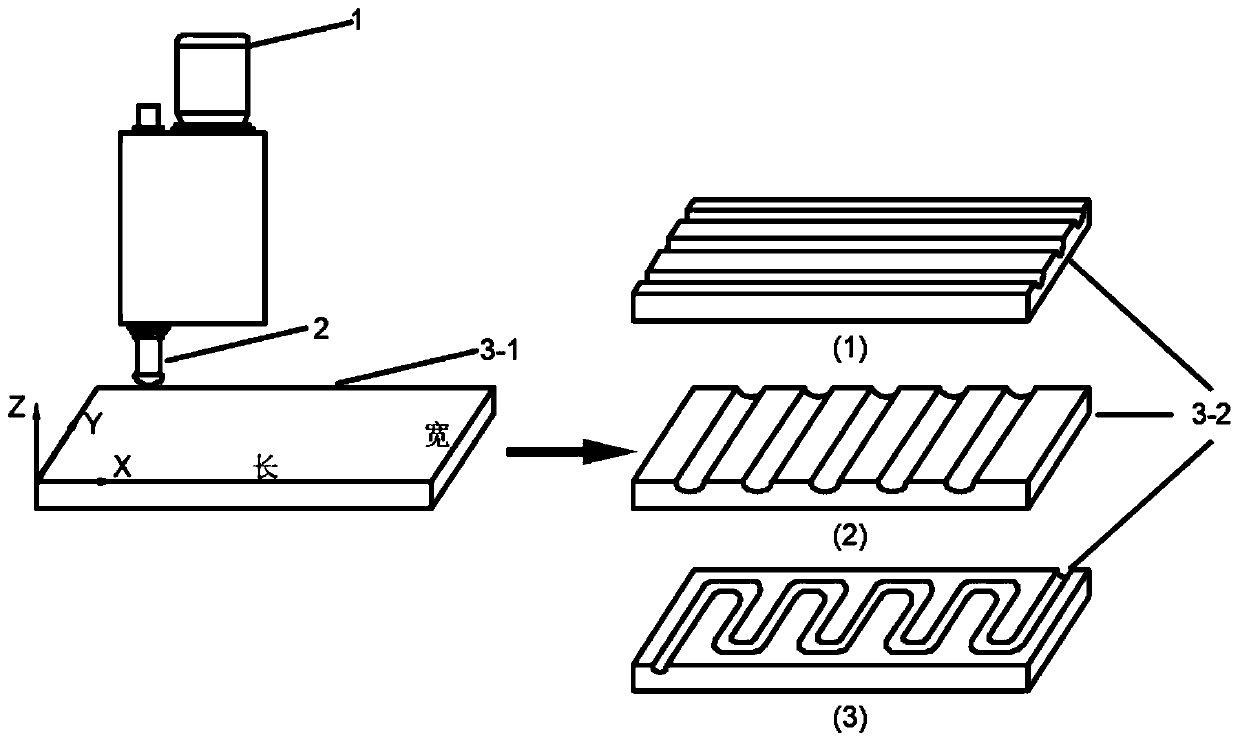

[0025] Step 1: Assemble the rolling head, fix the plate on the fixture of the three-axis CNC milling machine, and establish a three-axis coordinate system with the surface (X, Y) and the top (Z) of the plate.

[0026] by figure 2 As shown in (1): Accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com