High-temperature flue gas denitration catalyst and preparation method thereof

A denitrification catalyst and high-temperature flue gas technology, applied in the field of denitrification catalysts, can solve the problems of high-temperature denitrification activity to be further improved, achieve good denitrification activity and stability, avoid crystal transformation, and have good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

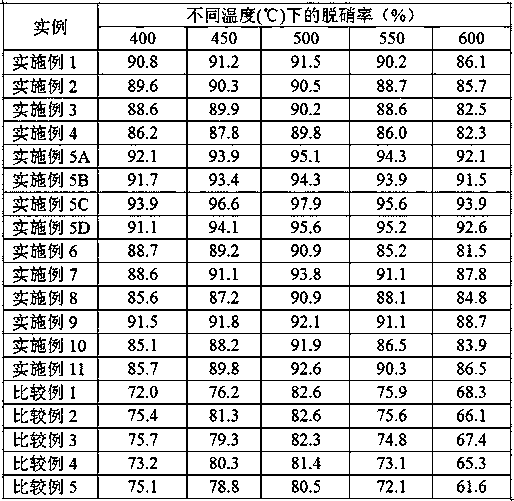

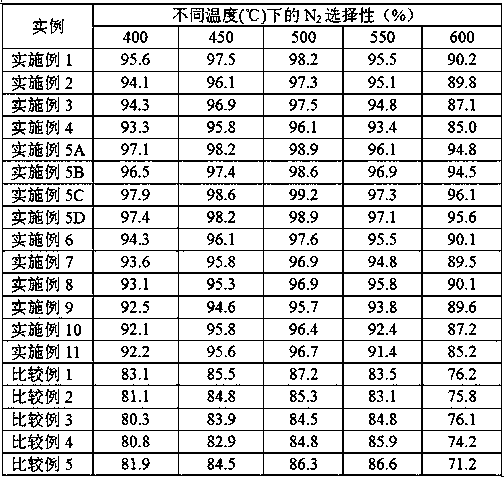

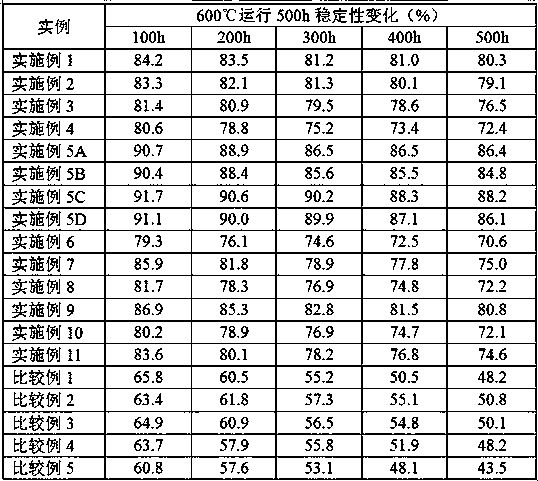

Examples

Embodiment 1

[0029] (1) TiO 2 -ZrO 2 -Preparation of molecular sieve composite carrier: firstly, 4kgTiO 2 (Anatase type, specific surface area 200m 2 / g, particle size D502 -ZrO 2 - Molecular sieve composite carrier.

[0030] (2) Loading of active components and additives: the TiO prepared in step (1) 2 -ZrO 2 - The molecular sieve composite carrier is impregnated in an impregnation solution containing 0.5mol / L ammonium tungstate and 0.3mol / L cerium nitrate for 10 minutes. After taking it out, it was dried at 100°C for 8 hours and calcined at 450°C for 10 hours to obtain a denitration catalyst powder.

[0031] (3) Honeycomb catalyst molding: combine 80 parts of the denitration catalyst powder prepared in step (2) with 6 parts of glass fiber, 0.1 part of wood pulp, 0.5 part of polyacrylamide, 2 parts of carboxymethyl cellulose, and 8 parts of ammonia water , 20 parts of deionized water, kneading, aging for 24 hours, extrusion and other processes to prepare the honeycomb body. The hon...

Embodiment 2

[0034] The preparation process and operating conditions are the same as those in Example 1, except that the silicoaluminophosphate molecular sieve is SAPO-20 molecular sieve. Among the catalysts, based on the total mass of the catalyst, TiO 2 Content 69%, ZrO 2 The content is 9%, the content of silicoaluminophosphate molecular sieve is 8%, WO 3 Content 4.9%, CeO 2 The content is 1.2%, and the glass fiber content is 7.0%.

Embodiment 3

[0036] The preparation process and operating conditions are the same as those in Example 1, except that the silicoaluminophosphate molecular sieve is SAPO-40 molecular sieve. Among the catalysts, based on the total mass of the catalyst, TiO 2 Content 70.5%, silicoaluminophosphate molecular sieve content 5.5%, ZrO 2 The content is 8%, WO 3 Content 4.6%, CeO 2 The content is 1.5%, and the glass fiber content is 6.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com