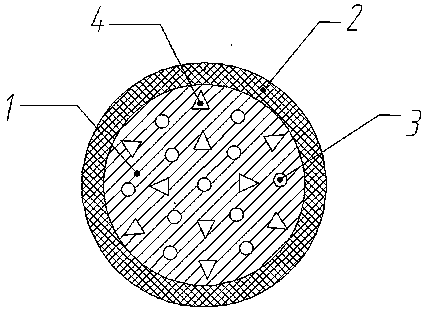

Multi-component composite high-first-effect lithium battery negative electrode material and preparation method thereof

A negative electrode material and multi-component composite technology, which is applied in the field of multi-component composite lithium battery negative electrode materials and its preparation, can solve the problems of reduced initial charge/discharge efficiency, increased irreversible capacity, unstable slurry, etc., to improve Coulombic efficiency and cycle performance , facilitate large-scale production, and the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

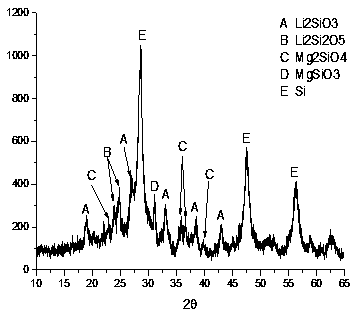

[0040] A certain amount of Si powder, SiO 2 Powder and metal magnesium powder are evenly mixed and added to a vacuum furnace for heat treatment. Heated to 1100°C under the condition of 500Pa vacuum degree, and the heat treatment time was 1h. The above powder is sublimated under high temperature and vacuum conditions, and the silicon oxide precursor uniformly doped with magnesium is obtained after the steam is condensed. Then crush and sieve to obtain particles with a particle size of 1-10um.

[0041] The particles obtained above were loaded into a CVD furnace, and propylene with a flow rate of 9 L / min and argon gas with a flow rate of 18 L / min were fed in for a deposition time of 1 h. Propylene is cracked at high temperature, pyrolytic carbon is coated on the particle surface, and a carbon-coated magnesium-doped SiO composite powder is obtained, and the thickness of the carbon coating layer is 80nm. Mix the composite powder obtained above with a certain amount of Li3N powde...

Embodiment 2

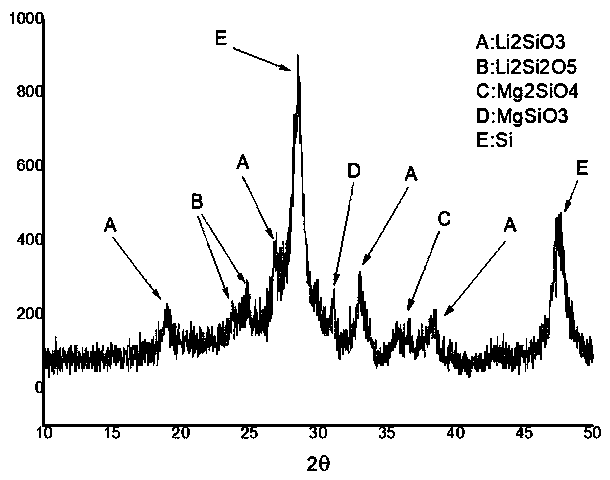

[0044] Lithium and magnesium co-doping are performed simultaneously using a multi-deposition chamber CVD furnace. Put a certain amount of Si powder and SiO powder with median diameter D50=5μm mixed uniformly in the deposition chamber 1 respectively. 2 powder, put a certain amount of magnesium powder in the deposition chamber 2, and put a certain amount of LiCl powder in the deposition chamber 3. Deposition chamber 1 is heated to 1100°C to make Si and SiO 2 sublimation. The deposition chamber 2 is heated to 1100°C to sublimate the Mg powder. The deposition chamber 3 is heated to 950° C. to vaporize LiCl. The three deposition chambers were all evacuated, the vacuum degree was controlled at 100 Pa, and the reaction time was controlled at 1 h. Then the gasified LiCl vapor, SiO vapor and Mg vapor were co-deposited in the collection chamber to obtain magnesium and lithium co-doped SiO composite powder. Then crush and sieve to obtain particles with a particle size of 1-10um.

[...

Embodiment 3~10

[0048] Other steps are identical with embodiment 1 with process parameter, difference is that Si powder that adds, SiO 2 Powder, metal magnesium powder and Li3N powder are different in quality, change the molar ratio of lithium atoms to magnesium atoms, and the content of lithium silicate and magnesium silicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com