Cable and method of manufacturing cable

A cable and outer layer technology, which is applied in the field of electric power equipment, can solve the problems of human injury, affecting the progress of cable installation, and the cable sheath is easily damaged by mice, etc., so as to reduce the damage caused by gnawing, the tensile strength of the skin and the tear strength are outstanding, Get a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

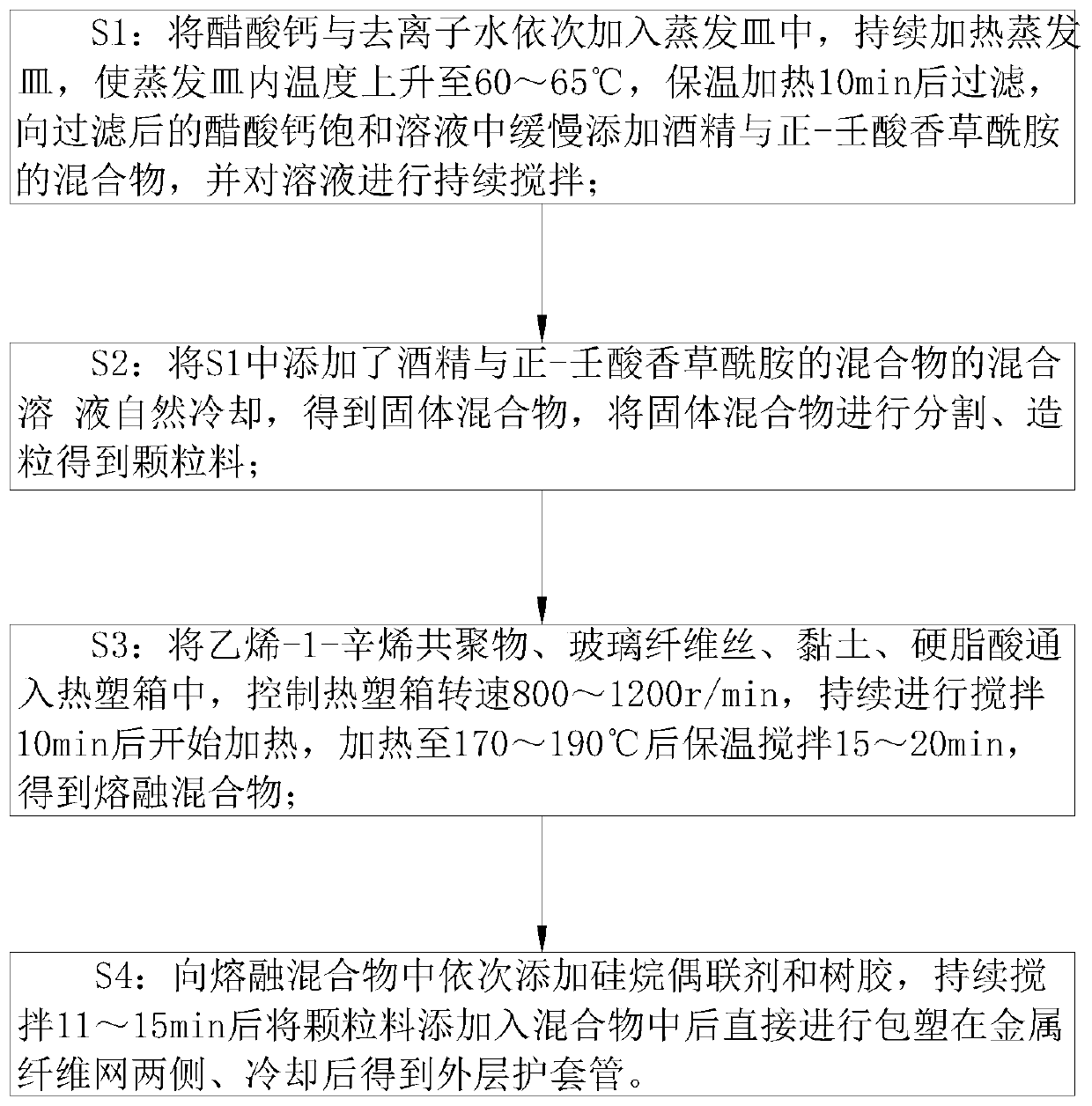

[0044] As an embodiment of the present invention, the preparation method of the outer sheath tube 1 is as follows:

[0045] S1: Add calcium acetate and deionized water to the evaporating dish in turn, continue to heat the evaporating dish, make the temperature inside the evaporating dish rise to 60-65°C, keep warm for 10 minutes and then filter, slowly add alcohol to the filtered calcium acetate saturated solution and the mixture of n-nonanoic acid vanillylamide, and the solution is continuously stirred; calcium acetate is dissolved in deionized water under heating conditions, and the ratio of calcium acetate to water is adjusted so that the calcium acetate aqueous solution is saturated, and then the The mixed solution of alcohol and n-nonanoic acid vanillylamide is added to the calcium acetate aqueous solution, and the mixed solution gradually solidifies after the cooling treatment. Acid vanillamide is uniformly dispersed and its properties do not change;

[0046] S2: natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com