Surface-enhanced Raman scattering substrate and preparation method thereof

A surface-enhanced Raman, substrate technology, applied in the field of detection, can solve the problems of neglect, strong coupling interaction force confusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

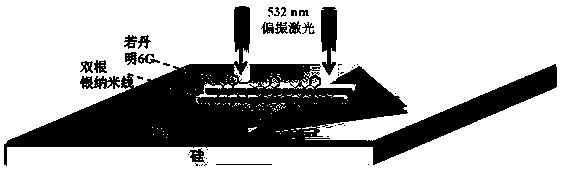

[0027] A method for preparing a silver nanowire / molybdenum disulfide composite material surface-enhanced Raman scattering substrate, comprising the following steps:

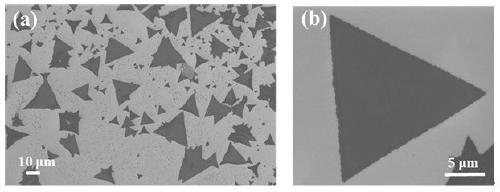

[0028] (1) Chemical vapor deposition (CVD) growth of molybdenum disulfide nanosheets: place sulfur powder with a purity of 99.5% in a quartz boat and connect it with a self-made push rod, and place it in the first horizontal tube furnace. At the front end of the heating zone, place molybdenum trioxide powder with a purity of 99.99% in another quartz boat, which is placed in the center of the second heating zone of the horizontal tube furnace, and the distance between the sulfur source and the molybdenum source is 10cm. The silicon growth substrate covered with a 285nm silicon dioxide layer was ultrasonically cleaned with acetone, ethanol, and deionized water, respectively, and then dried and placed upside down on the top of the second quartz boat. Use a vacuum pump to evacuate the horizontal tube furnace to 100 m...

Embodiment 2

[0037] Step (1) to step (3) are the same as in Example 1,

[0038] (4) Raman measurement: 10 μL was dropped on the surface of the composite material obtained in step (3) with a concentration of 10 -6 The mol / L rhodamine 6G solution was tested by Raman spectroscopy on silver nanowires / molybdenum disulfide at a light polarization angle of 45°; the laser parameters were set as follows: the laser spot is 2μm, the wavelength is 532nm, and the power is 5mW.

Embodiment 3

[0044] Step (1) to step (3) are the same as in Example 1,

[0045] (4) Raman measurement: 10 μL was dropped on the surface of the composite material obtained in step (3) with a concentration of 10 -6 The mol / L rhodamine 6G solution was tested by Raman spectroscopy on silver nanowires / molybdenum disulfide at a light polarization angle of 90°; the laser parameters were set as follows: the laser spot is 2μm, the wavelength is 532nm, and the power is 5mW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com