Equipment and method for preparing high-performance aluminum alloy material based on genome high-flux technology

An aluminum alloy material, high-throughput technology, applied in the direction of stirring devices, furnace components, lighting and heating equipment, etc., can solve the problems of accelerating material screening and optimization, achieve high batching accuracy, improve comprehensive performance, and realize mechanical automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

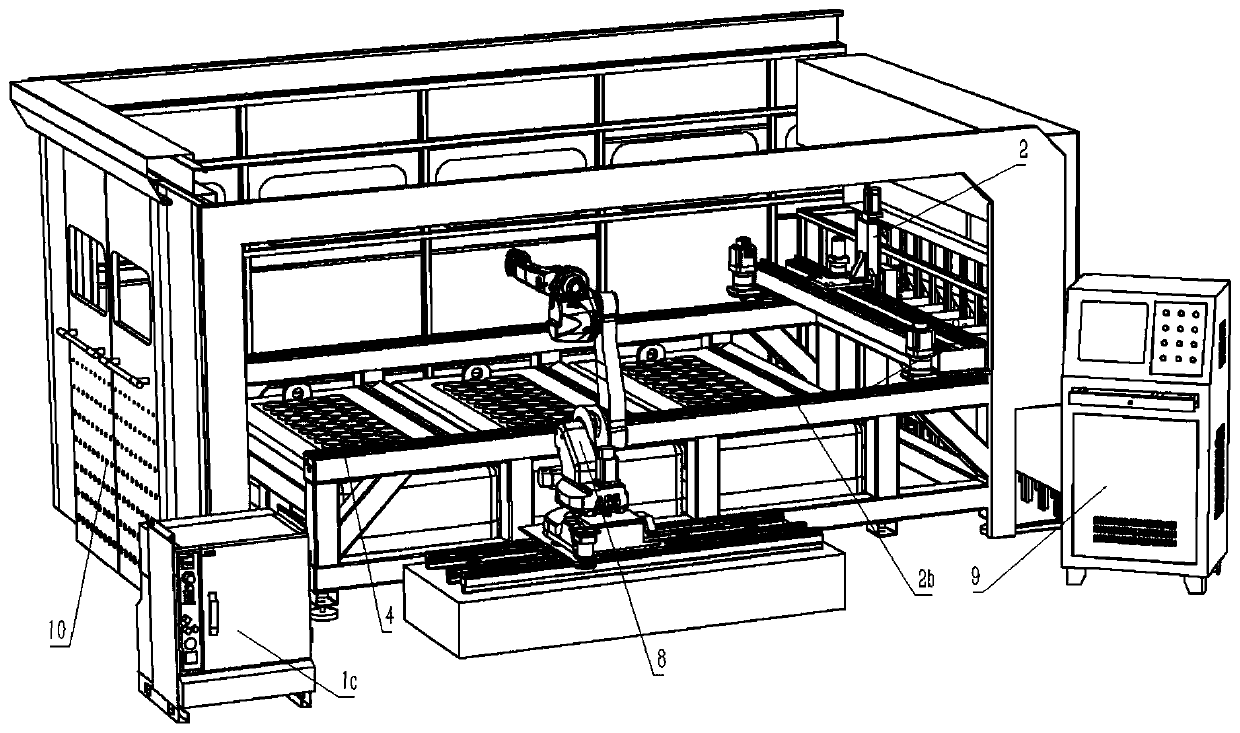

[0068] The preparation equipment of high-performance aluminum alloy materials based on the genome high-throughput technology proposed by the present invention is divided into four parts according to functions, one part is the element box assembly, the second is the feeding hopper mechanism, the third is the melting device, and the fourth is the Peripheral auxiliary devices, these four functional devices coordinate and cooperate to complete the preparation of the entire high-performance aluminum alloy material.

[0069] The element assembly 1 designed in the present invention is composed of an element box 1a, an element box auger 1b, an element box controller 1c and the like. The element box auger 1b is a screw rod structure, connected with the element box 1, and the element box auger is welded directly under the element box 1a. The number of element boxes 1a in the present invention is 18, and the 18 element boxes 1a are loaded with 18 kinds of aluminum alloy master alloy part...

Embodiment

[0079] First, we prepare aluminum alloy master alloys of various elements into particles with a shape of 2mmx2mmx2mm, and put the aluminum alloy master alloy particles 3 of various elements into different element boxes 1a respectively. In the present invention, the number of element boxes 1a is designed to be 18, and the 18 element boxes 1a are loaded with 18 kinds of aluminum alloy intermediate alloy particles of different elements, and the element boxes 1 are arranged in sequence. The feeding hopper 2f is arranged according to the calculation of the high-throughput computing industrial computer 9. The feeding hopper 2f arrives directly below the element box 1 according to the specified route, and the element box 1 starts feeding, and the intermediate alloy particles of an elemental aluminum alloy in the element box 1 fall into the In the feeding hopper 2f, after the feeding hopper 2f is loaded with the aluminum alloy intermediate alloy 3, the feeding hopper 2f arrives directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com