Cold-rolled bifocal plate as well as manufacturing method and application thereof

A manufacturing method and light plate technology, which is applied in metal rolling and other directions, can solve the problems that cold-rolled double-light plate cannot be satisfied at the same time, low roughness, etc., and achieve the effects of reducing bonding defects, low roughness, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] On the one hand, the embodiment of the present invention proposes a method for manufacturing a cold-rolled double-bright sheet.

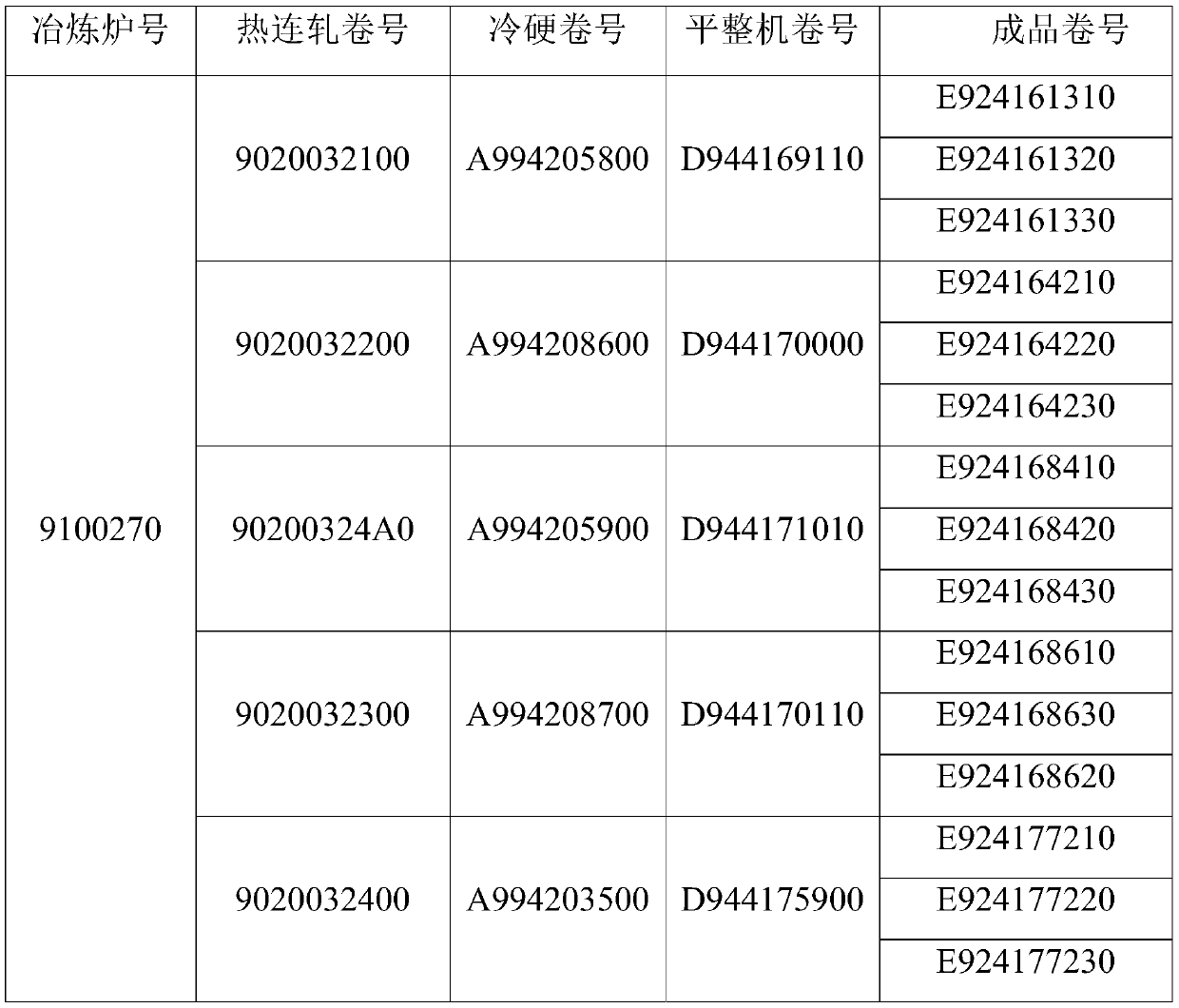

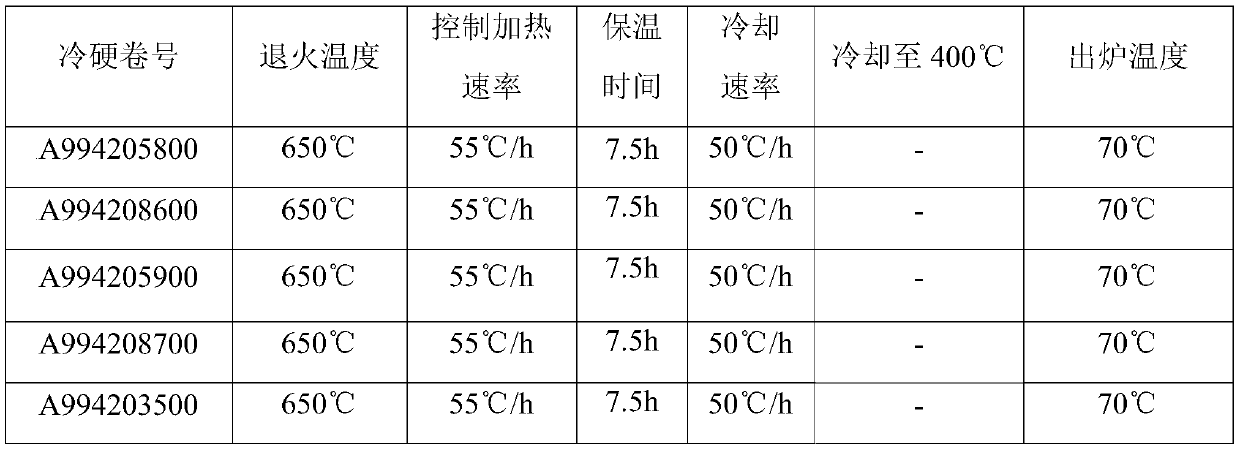

[0023] The slabs obtained from blast furnace molten iron smelting, converter molten steel smelting, LF molten steel refining, slab continuous casting, and soaking processes, the slabs are sequentially subjected to hot rolling, pickling and cold rolling, bell annealing, smoothing, and finishing processes. Get cold-rolled double-light board.

[0024] Among them, the carbon content of the argon station can be controlled at 0.1% to 0.16% in the converter molt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com