Vehicle-mounted organic garbage quick decomposition and fertilization system and method

A vehicle-mounted technology for organic waste, applied in the direction of organic fertilizer, organic fertilizer preparation, excretion fertilizer, etc., can solve the problems of complex composition, polluted crops, small scale, etc., and achieve the effect of high system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

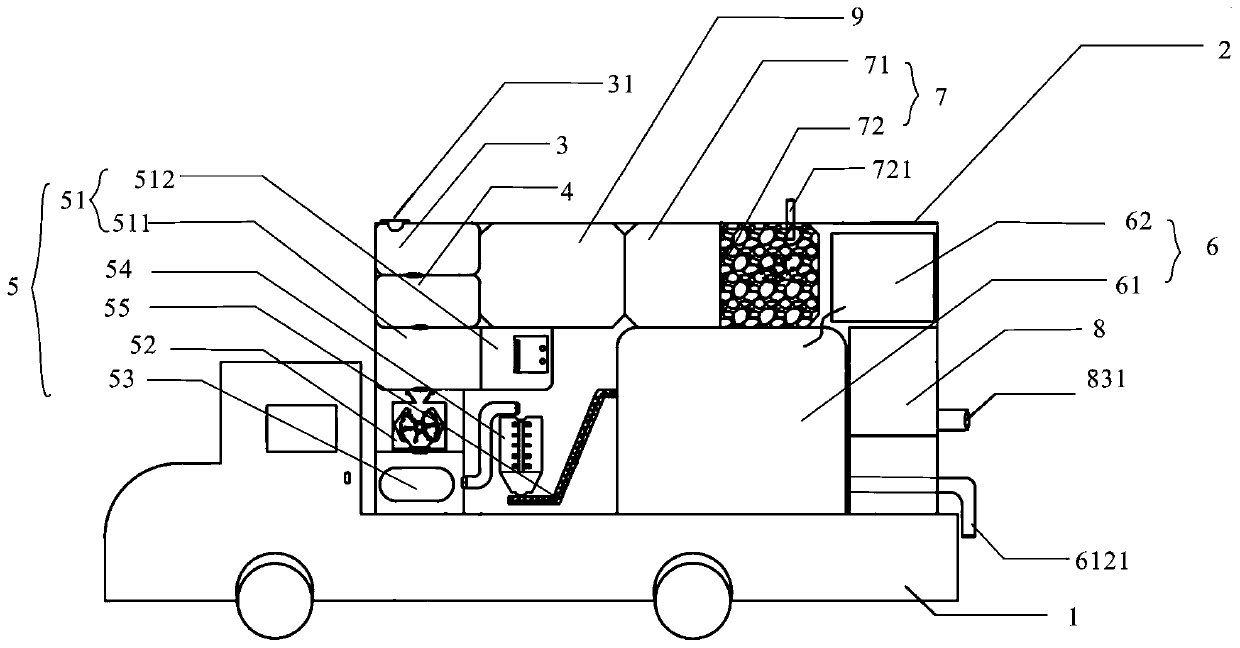

[0094] as attached Figure 1-3 As shown, a vehicle-mounted organic waste rapid decomposition and fertilization system includes a vehicle body 1 and a container casing 2, and the container casing 2 is installed on the vehicle body 1.

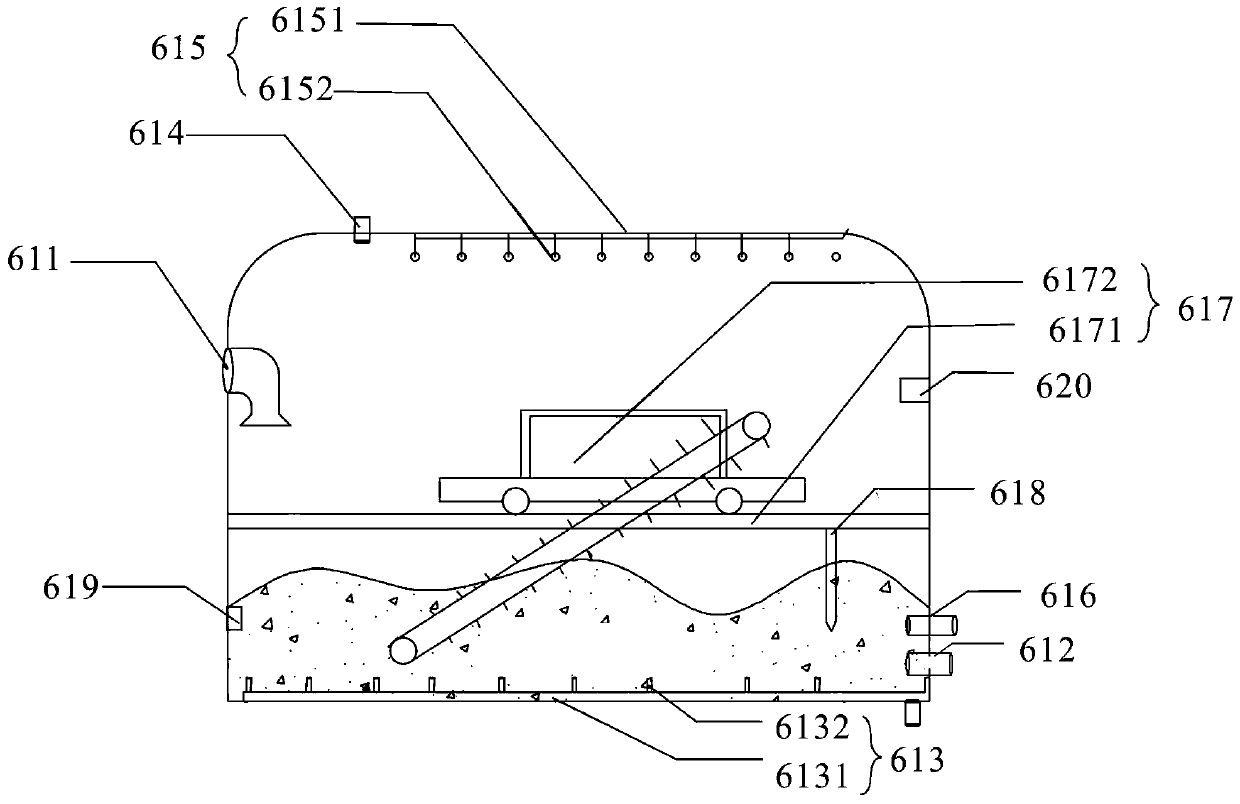

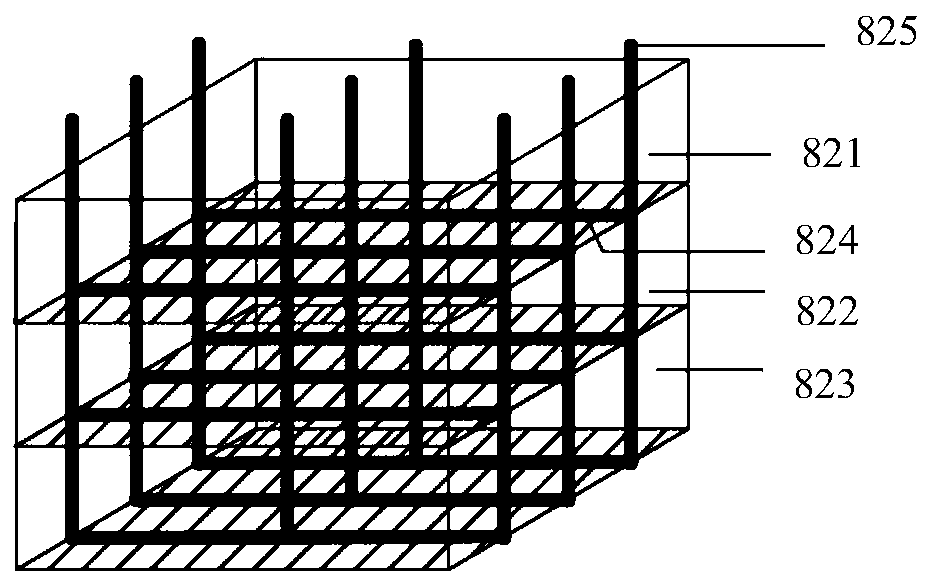

[0095] The container housing 2 is provided with a storage unit 3 , a feeding unit 4 , a pretreatment unit 5 , an aerobic fermentation unit 6 , a deodorization unit 7 and a leachate treatment unit 8 .

[0096] The outer wall of the storage unit 3 is provided with a material inlet 31 of the storage unit, and the bottom is connected to the feeding unit 4 through a switchable partition or a valve; the feeding unit 4 is provided with a conveyor belt, and the bottom of the feeding unit 4 is provided with a switchable partition plate or valve.

[0097] The pretreatment unit 5 includes a sorting device 51, a crushing device 52, a humidity regulating device 53, a stirring device 54 and a feeding device 55 which are connected in sequence;

[0098] Sortin...

Embodiment 2

[0151] Use the system and method in Example 1 for garbage disposal as an experimental group, and set up a control group: on the basis of Example 1, replace the composite bacterial liquid inoculated in the aerobic fermentation unit with the Bacillus megaterium bacterial liquid, and the bacteria Liquid concentration is 2.0×10 7 CFU / mL, the inoculation volume is 8‰.

[0152] After the fermentation, the fertilizers obtained by the two groups were tested for various indicators, and the mortality rate of roundworm eggs was calculated according to the number of roundworm eggs before garbage treatment. The results are shown in Table 1.

[0153] Table 1

[0154]

[0155]

[0156] Under the various technical parameters of the present invention, the various indexes of the prepared fertilizer are better, and are better than the index values in the "Biological Organic Fertilizer" (NY884-2012) standard.

Embodiment 3

[0158] Use the system and method in Example 1 to carry out garbage treatment, as an experimental group, and set up a control group: on the basis of Example 1, the processing time in the S5 step is adjusted, and the leachate is in the strengthened anaerobic hydrolysis reactor It stays for 6 hours inside, stays for 10 hours in the sequencing batch microbubble oxygenation device, and stays for 2.5 hours in the photocatalytic device.

[0159] The leachates obtained from the two groups of treatments were tested for various indicators, and the results are shown in Table 2.

[0160] Table 2

[0161] project test group control group COD (mg / L) 50 80 BOD 5 (mg / L)

[0162] It can be seen that under the technical scheme of the present invention, the effluent water quality is stable and reaches the urban greening and vehicle washing standards in "Urban Sewage Recycling Urban Miscellaneous Water Quality" (GB / T 18920-2002); it is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Filling density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com