High-wear-resistance far-infrared ceramic glazed brick and preparation method thereof

A kind of far-infrared ceramics and far-infrared technology, applied in the field of ceramic tile production and manufacturing, can solve the problems of rough texture, no mass production of far-infrared glazed tiles, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. The raw material formula of the green body is: 5% selected sodium stone powder, 15% medium temperature sand, 15% low temperature sodium sand, 18% Bangsha, 6% Shaoguan ball clay, 12% washed ball clay, 6% calcined bauxite, 1% black talc, 18% potassium aluminum sand, 4% raw mud. Its chemical composition is: SiO 2 : 63.5~65%, Al 2 o 3 : 21~24%, Fe 2 o 3 : 0.4~0.7%, TiO 2 : 0.25~0.35%, CaO: 0.25~0.35%, MgO: 0.5~0.80%, K 2 O: 2.0-2.4%, Na 2 O: 2.6-3.0%, loss on ignition: 4.5-5.5%. The raw materials are molded and dried by a press to obtain a green body. The expansion coefficient of the green body is 7.4816×10 -6 / K.

[0047] 2. Apply far-infrared glaze on the green body. The formula composition of the far-infrared surface glaze: far-infrared feldspar powder 35%, albite 13%, kaolin 9%, quartz sand 20%, zirconium silicate 10%, calcined kaolin 8%, alumina 5%. The chemical composition of the far-infrared glaze is: SiO 2 : 66.82%, Al 2 o 3 : 18.05%, Fe 2 o 3 : ...

Embodiment 2

[0055] The difference from Example 1 is that the highly transparent far-infrared glazed mineral composition is: far-infrared feldspar powder 25%, zinc oxide 8%, barium carbonate 5%, burnt talc 9%, kaolin 8%, glass frit 45% . The chemical composition of the high-transmittance far-infrared glaze is: SiO 2 : 59.24%, Al 2 o 3 : 6.11%, Fe 2 o 3 : 0.20%, TiO 2 : 0.26%, CaO: 8.38%, MgO: 4.12%, BaO: 3.89%, ZnO: 8.84%, K 2 O: 3.53%, Na 2 O: 1.02%, Rb 2 O: 107ppm, Y 2 o 3 : 77ppm, loss on ignition: 2.11%. The expansion coefficient of the high-transmitting far-infrared glaze is 6.1816×10 at 40°C to 400°C -6 / K.

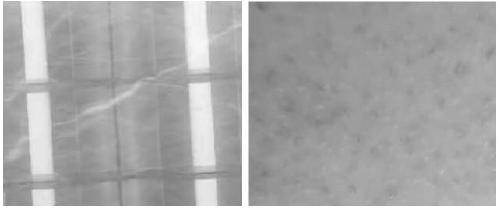

[0056] The surface of the resulting polished glazed tile is as image 3 As shown, the picture on the left is the actual photo, and the picture on the right is the photo of the glaze layer magnified 60 times. From the picture on the left, we can see that the reflection of the fluorescent tube is straight, with high mirror surface and strong sense of transparency. Fr...

Embodiment 3

[0058] The difference from Example 1 is that the highly transparent far-infrared glazed mineral composition is: far-infrared feldspar powder 27%, zinc oxide 12%, barium carbonate 8%, burnt talc 9%, kaolin 9%, glass frit 35% . The chemical composition of the high-transmittance far-infrared glaze is: SiO 2 : 54.51%, Al 2 o 3 : 6.18%, Fe 2 o 3 : 0.21%, TiO 2 : 0.26%, CaO: 7.37%, MgO: 4.06%, BaO: 6.22%, ZnO: 12.61%, K 2 O: 3.44%, Na 2 O: 1.01%, Rb 2 O: 116ppm, Y 2 o 3 : 84ppm, loss on ignition: 2.88%. The expansion coefficient of the high-transmittance far-infrared glaze is 6.1316×10 at 40°C to 400°C -6 / K.

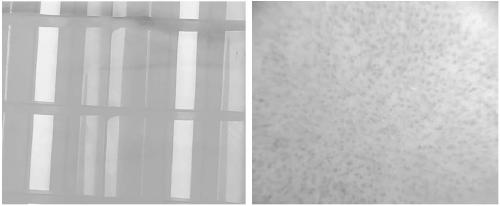

[0059] The surface of the resulting polished glazed tile is as Figure 4 As shown, the picture on the left is the actual photo, and the picture on the right is the photo of the glaze layer magnified 60 times. From the picture on the left, we can see that the reflection of the fluorescent tube is straight, with high mirror surface and strong sense of transparency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com